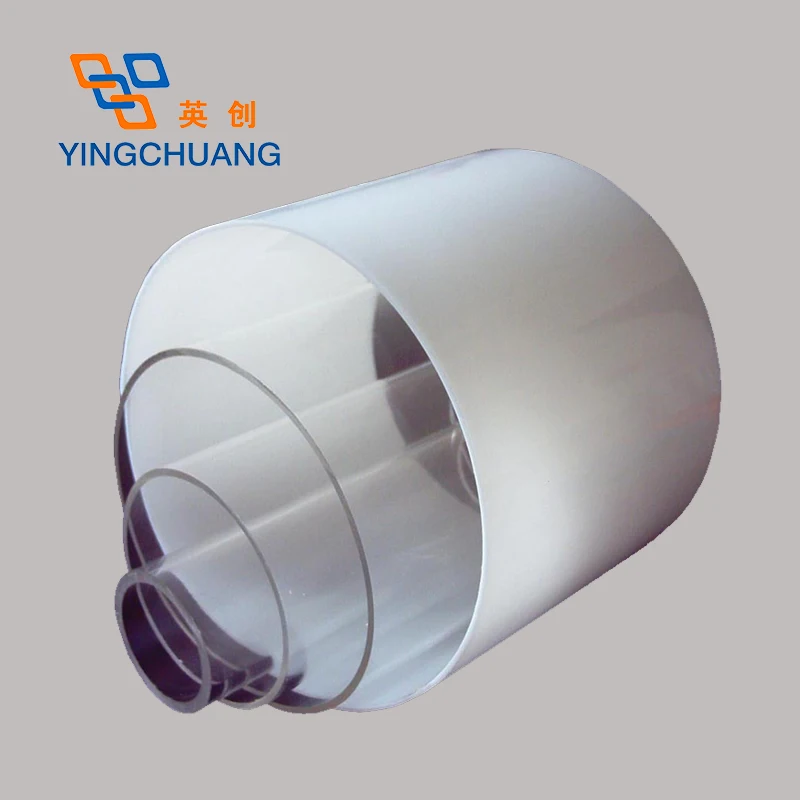

pvdf tube

PVDF (Polyvinylidene fluoride) tubes represent a crucial advancement in industrial fluid handling systems. These high-performance tubes combine exceptional chemical resistance with remarkable mechanical properties, making them ideal for demanding applications across various industries. PVDF tubes feature outstanding resistance to acids, bases, and organic solvents, while maintaining their structural integrity across a wide temperature range from -40°C to 140°C. Their non-toxic nature and compliance with FDA standards make them particularly valuable in pharmaceutical and food processing applications. The tubes excellent UV resistance and weather durability ensure long-term reliability in outdoor installations. Moreover, PVDF tubes exhibit low permeability to most gases and liquids, providing superior barrier properties. Their smooth inner surface prevents bacterial growth and reduces the risk of contamination, while their flexibility allows for easy installation and maintenance. These tubes also demonstrate remarkable resistance to abrasion and wear, contributing to their extended service life and reduced maintenance requirements.