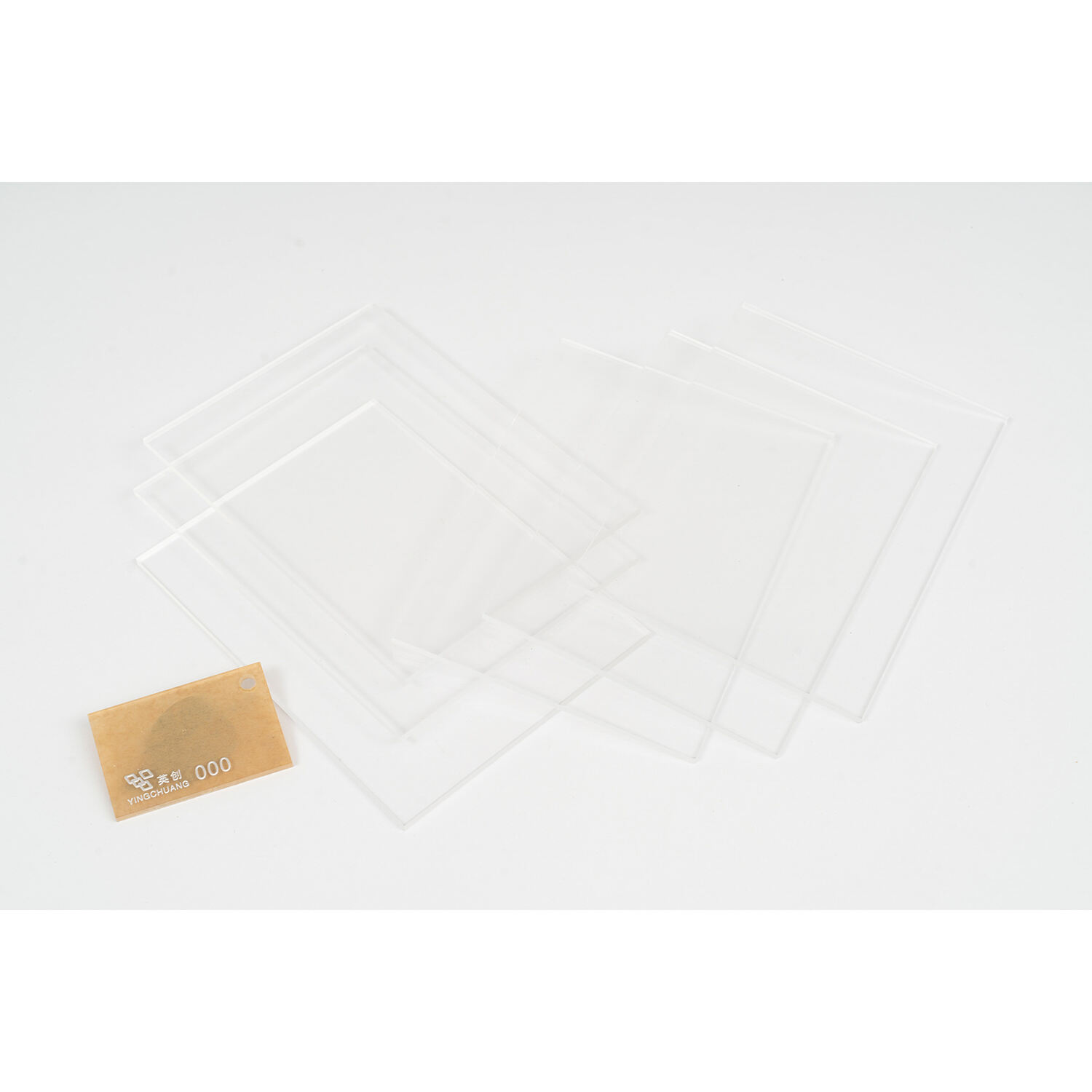

pvdf plate

PVDF (Polyvinylidene Fluoride) plates are advanced engineering materials that combine exceptional chemical resistance with outstanding mechanical properties. These plates are manufactured through a sophisticated process that ensures uniform thickness and consistent quality throughout the material. PVDF plates exhibit remarkable resistance to harsh chemicals, UV radiation, and extreme temperatures, making them ideal for demanding industrial applications. The material's inherent properties include excellent thermal stability, maintaining its structural integrity across a wide temperature range from -30°C to 150°C. PVDF plates are particularly valued for their self-extinguishing properties and low smoke emission characteristics, contributing to enhanced safety in various installations. The material's smooth surface finish and low friction coefficient make it suitable for applications requiring minimal maintenance and extended service life. In industrial settings, PVDF plates are extensively used in chemical processing equipment, semiconductor manufacturing, and water treatment facilities. Their non-toxic nature and compliance with FDA regulations also make them suitable for food processing and pharmaceutical applications. The plates can be fabricated into various shapes and sizes, offering versatility in design and implementation across different sectors.