Understanding the Versatility of PMMA in Contemporary Manufacturing

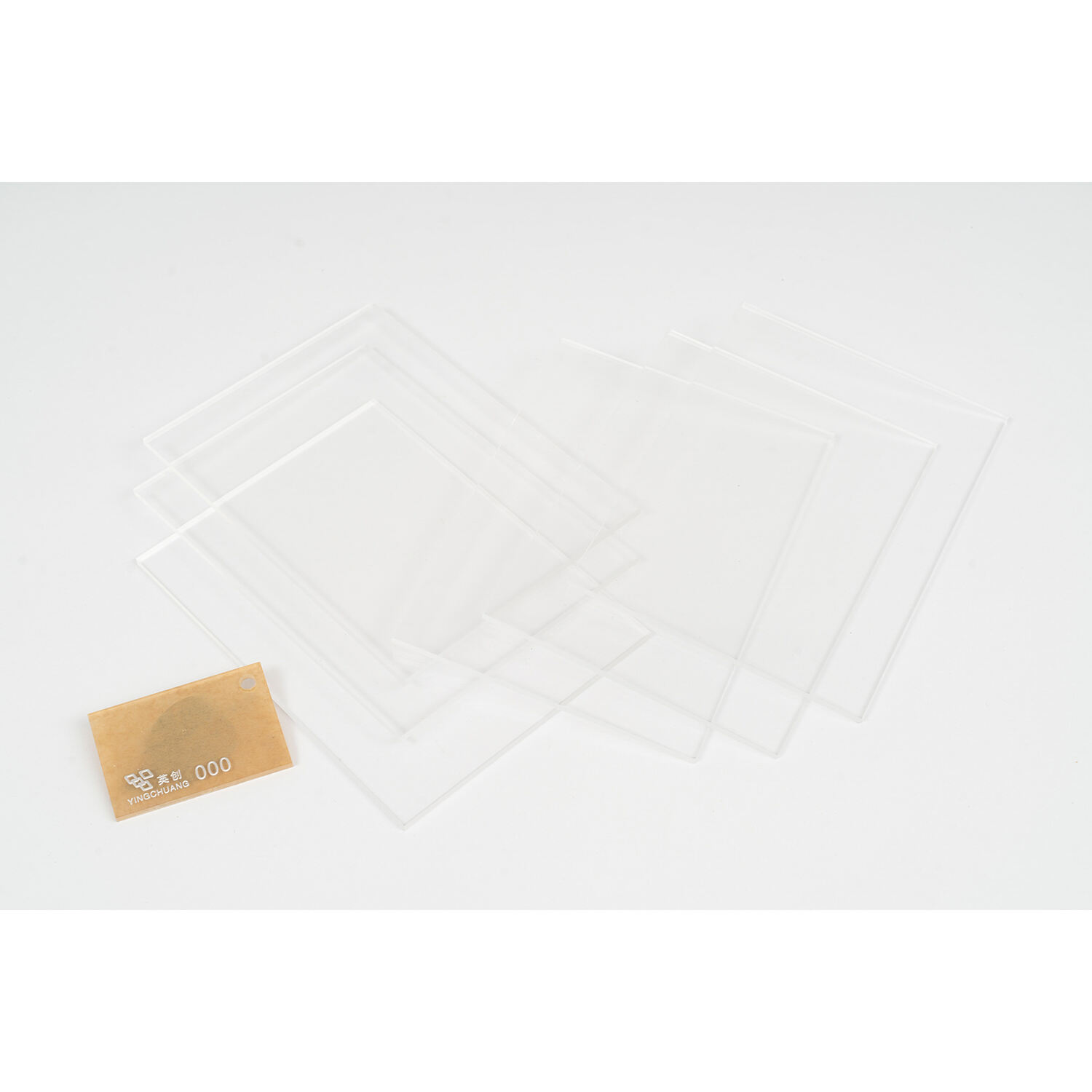

In today's rapidly evolving industrial landscape, PMMA has emerged as one of the most versatile and widely used thermoplastic materials. Also known as acrylic or poly(methyl methacrylate), PMMA combines exceptional optical clarity with impressive durability, making it an indispensable component across numerous sectors. The material's unique properties, including its weather resistance, lightweight nature, and excellent light transmission capabilities, have revolutionized manufacturing processes and product designs worldwide.

The significance of PMMA in modern industry cannot be overstated. From architectural applications to medical devices, this remarkable polymer continues to shape innovation and drive technological advancement. As we explore its diverse applications, we'll discover how PMMA has become integral to both everyday products and cutting-edge developments.

Architectural and Construction Applications

Transparent Building Elements

The construction industry has embraced PMMA as a superior alternative to traditional glass in many applications. Building designers and architects frequently specify PMMA for skylights, window panels, and transparent roofing elements. The material's exceptional clarity and impact resistance make it ideal for these applications, while its lighter weight reduces structural load requirements compared to glass installations.

Modern architectural projects increasingly feature PMMA in innovative ways, such as creating stunning transparent facades and decorative elements that combine functionality with aesthetic appeal. The material's ability to be molded into various shapes and sizes allows architects to realize complex designs that would be impossible with conventional materials.

Safety and Security Barriers

PMMA's robust nature makes it an excellent choice for safety barriers and security installations. From bus shelters to acoustic barriers along highways, the material provides clear visibility while offering protection from environmental elements and impact. The polymer's resistance to yellowing and weathering ensures these installations maintain their appearance and structural integrity over extended periods.

Medical and Healthcare Implementations

Biomedical Devices

The healthcare sector relies heavily on PMMA for various medical applications, particularly in the manufacture of biomedical devices. The material's biocompatibility and stability make it perfect for contact lenses, dental implants, and bone cement used in orthopedic surgery. The polymer's optical clarity and durability have made it a standard material in the production of intraocular lenses for cataract surgery.

Research continues to expand PMMA's role in medical innovations, with new applications emerging in tissue engineering and drug delivery systems. The material's versatility allows for precise customization to meet specific medical requirements while maintaining strict safety standards.

Laboratory Equipment

Scientific laboratories worldwide utilize PMMA in various equipment and tools. From test tubes to optical components in diagnostic devices, the material's chemical resistance and optical properties make it invaluable in research and clinical settings. The polymer's ability to maintain clarity while resisting common laboratory chemicals has established it as a preferred material for many analytical instruments.

Automotive Industry Applications

Lighting Components

The automotive sector extensively uses PMMA in vehicle lighting systems, including headlights, taillights, and interior illumination. The material's excellent light transmission properties and weather resistance make it ideal for these applications. Modern vehicle designs increasingly incorporate complex lighting geometries that are only possible through PMMA's formability and optical characteristics.

Automotive manufacturers value PMMA for its ability to maintain clarity and performance throughout a vehicle's lifetime, even under extreme weather conditions and constant UV exposure. The material's impact resistance also contributes to improved safety standards in automotive design.

Interior and Exterior Trim

Beyond lighting applications, PMMA finds extensive use in automotive interior and exterior trim components. From instrument panel covers to decorative elements, the material's versatility allows designers to create sophisticated and functional automotive parts. The polymer's ability to be colored and textured provides additional design flexibility while maintaining structural integrity.

Electronics and Display Technology

Screen Protectors and Displays

The electronics industry relies heavily on PMMA for screen protectors and display components. The material's optical clarity and scratch resistance make it ideal for protecting smartphones, tablets, and other electronic devices. As display technology evolves, PMMA continues to play a crucial role in developing new screen solutions that combine durability with superior visual performance.

Light Guide Panels

PMMA's exceptional light transmission properties make it essential in manufacturing light guide panels for LCD displays and LED lighting systems. These components ensure uniform light distribution and improved energy efficiency in modern display technologies. The material's ability to be precisely modified for specific optical properties enables manufacturers to create increasingly sophisticated lighting solutions.

Future Trends and Innovations in PMMA Applications

Sustainable Development

The future of PMMA applications is closely tied to sustainability initiatives. Manufacturers are developing improved recycling methods and exploring bio-based alternatives to traditional PMMA production. These innovations aim to reduce environmental impact while maintaining the material's superior performance characteristics.

Research into sustainable PMMA alternatives and recycling technologies continues to advance, promising more environmentally friendly solutions for various industrial applications. The focus on sustainability is driving new developments in material science and manufacturing processes.

Advanced Manufacturing Techniques

Emerging technologies such as 3D printing and advanced molding processes are expanding PMMA's application potential. These manufacturing innovations enable the creation of complex geometries and integrated functions that were previously impossible. The combination of PMMA's versatility with new production methods is opening up exciting possibilities across multiple industries.

Frequently Asked Questions

What makes PMMA different from other transparent plastics?

PMMA stands out due to its exceptional optical clarity, weather resistance, and mechanical properties. Unlike other transparent plastics, it maintains its clarity over time without yellowing, offers superior scratch resistance, and provides excellent UV protection while being lighter than glass.

How long does PMMA typically last in outdoor applications?

When properly installed and maintained, PMMA can last 20-30 years in outdoor applications. The material's inherent UV resistance and weather durability make it highly suitable for long-term exterior use, though actual lifespan depends on environmental conditions and specific application requirements.

Can PMMA be recycled?

Yes, PMMA is fully recyclable and can be processed back into its original monomer form through depolymerization. This characteristic makes it an environmentally responsible choice for various applications, as the recycled material maintains properties similar to virgin PMMA.