pvdf welding rod

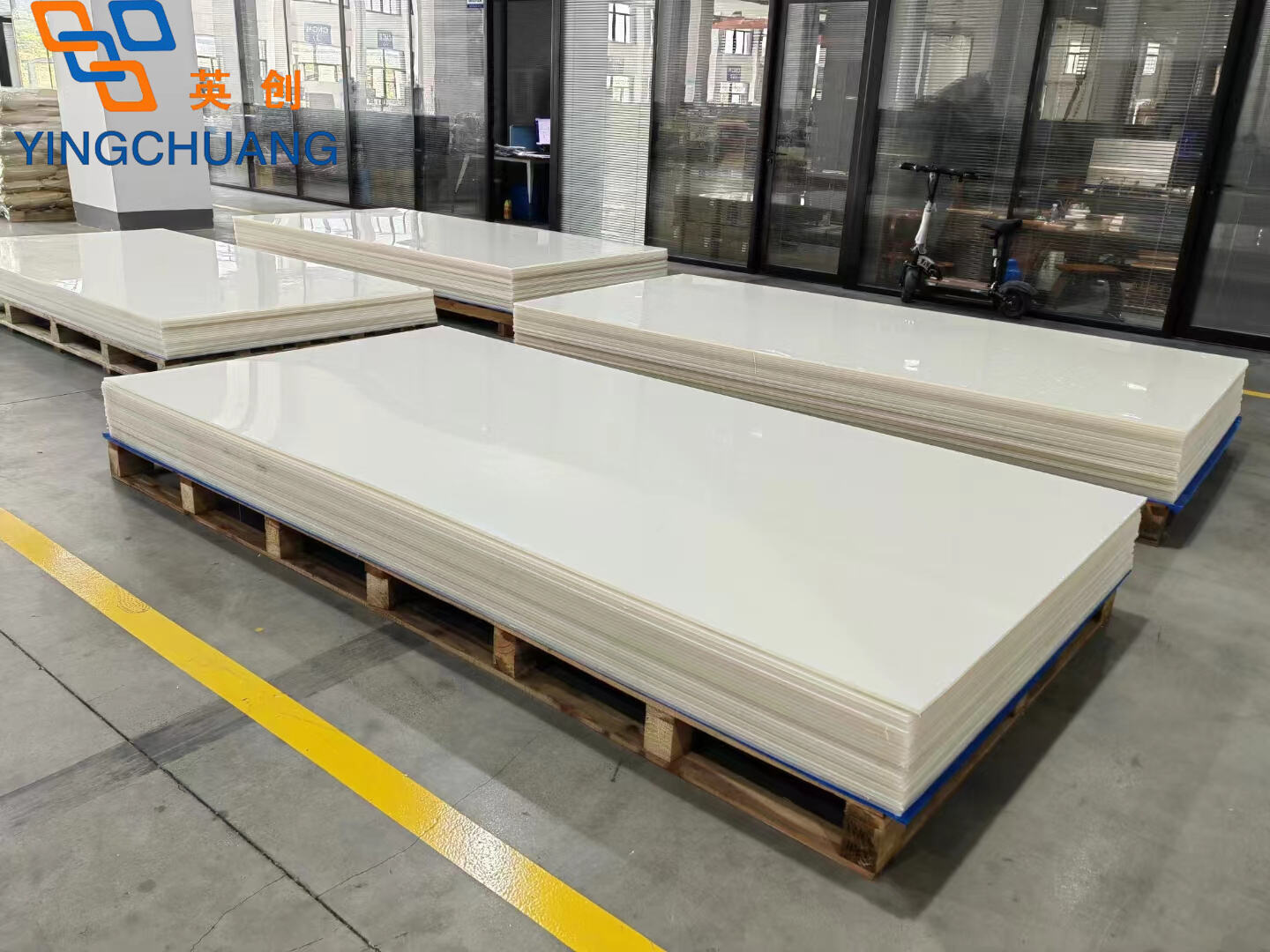

PVDF welding rods are essential components in the plastic welding industry, specifically designed for joining polyvinylidene fluoride (PVDF) materials. These high-performance thermoplastic welding rods offer exceptional chemical resistance, thermal stability, and mechanical strength, making them ideal for critical applications in various industries. The rods are manufactured using premium-grade PVDF material, ensuring consistent quality and reliable performance during welding operations. With a melting point range of 320-340°F (160-171°C), PVDF welding rods provide excellent fusion characteristics and create strong, durable bonds. The rods are available in different diameters and lengths to accommodate various welding requirements and equipment specifications. They are particularly valued in chemical processing, semiconductor manufacturing, and water treatment facilities where material purity and chemical resistance are paramount. The welding process involves heating both the rod and the base material to their melting points, allowing them to fuse together and create a homogeneous joint that maintains the original material's properties. These rods are compatible with both hot gas welding and extrusion welding techniques, offering flexibility in application methods.