pvdf board

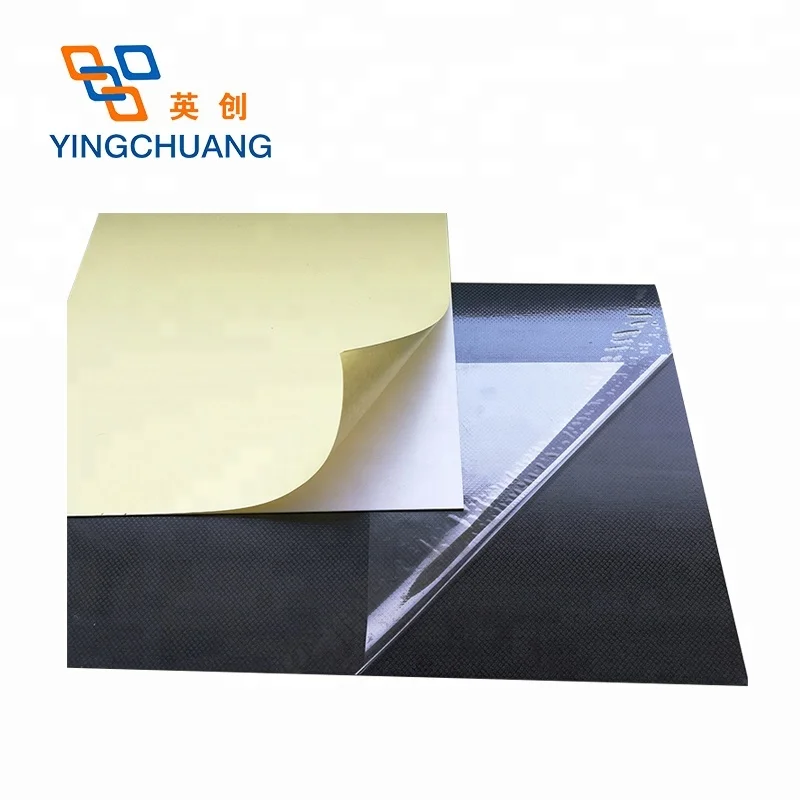

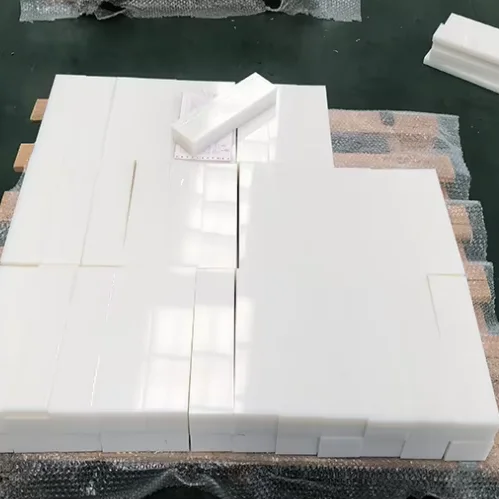

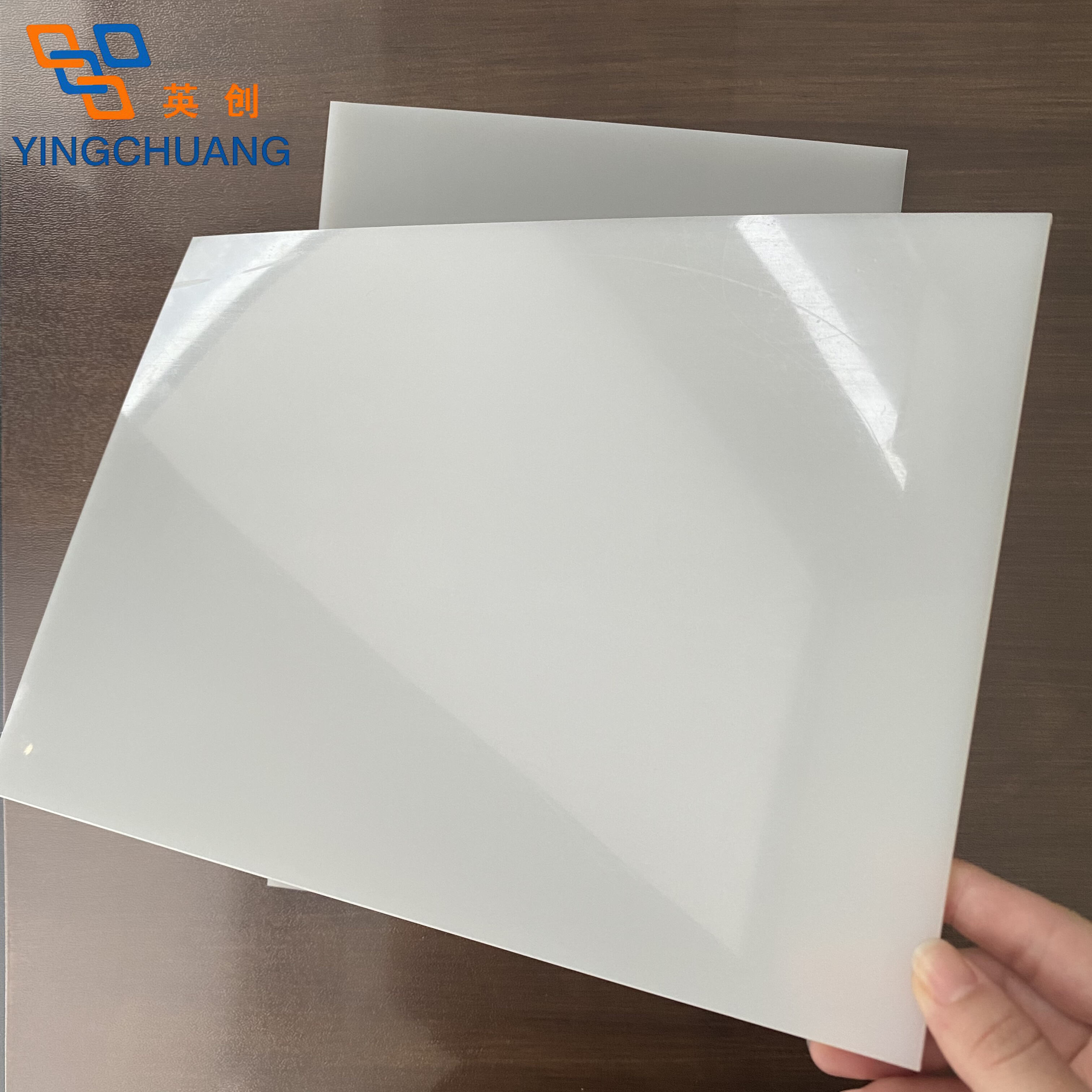

PVDF (Polyvinylidene Fluoride) board is a high-performance engineering material that combines exceptional chemical resistance with outstanding mechanical properties. This versatile material consists of a thermoplastic fluoropolymer that offers remarkable durability and reliability across various industrial applications. The board features a unique molecular structure that provides superior resistance to UV radiation, chemicals, and extreme temperatures, ranging from -40°C to 150°C. PVDF boards are manufactured through a sophisticated extrusion process that ensures consistent quality and dimensional stability. The material's inherent properties make it particularly valuable in environments where traditional materials would deteriorate quickly. These boards are available in various thicknesses and sizes, allowing for customization according to specific project requirements. The non-stick surface of PVDF boards prevents material buildup and facilitates easy cleaning, making them ideal for use in chemical processing equipment, semiconductor manufacturing, and pharmaceutical production facilities. Additionally, the material's low flame spread characteristics and minimal smoke generation contribute to its safety profile, making it suitable for applications where fire resistance is crucial.