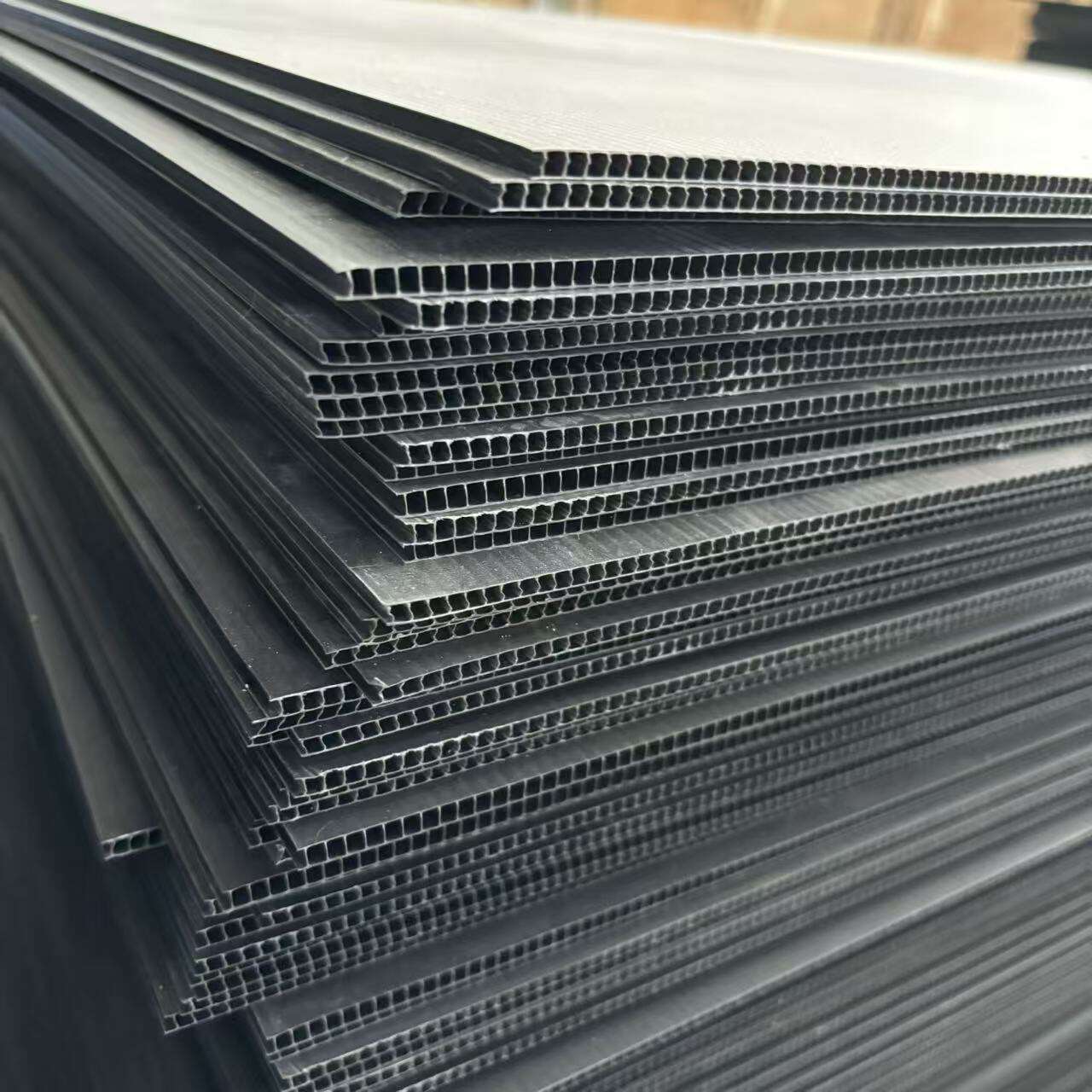

pp hollow sheet price

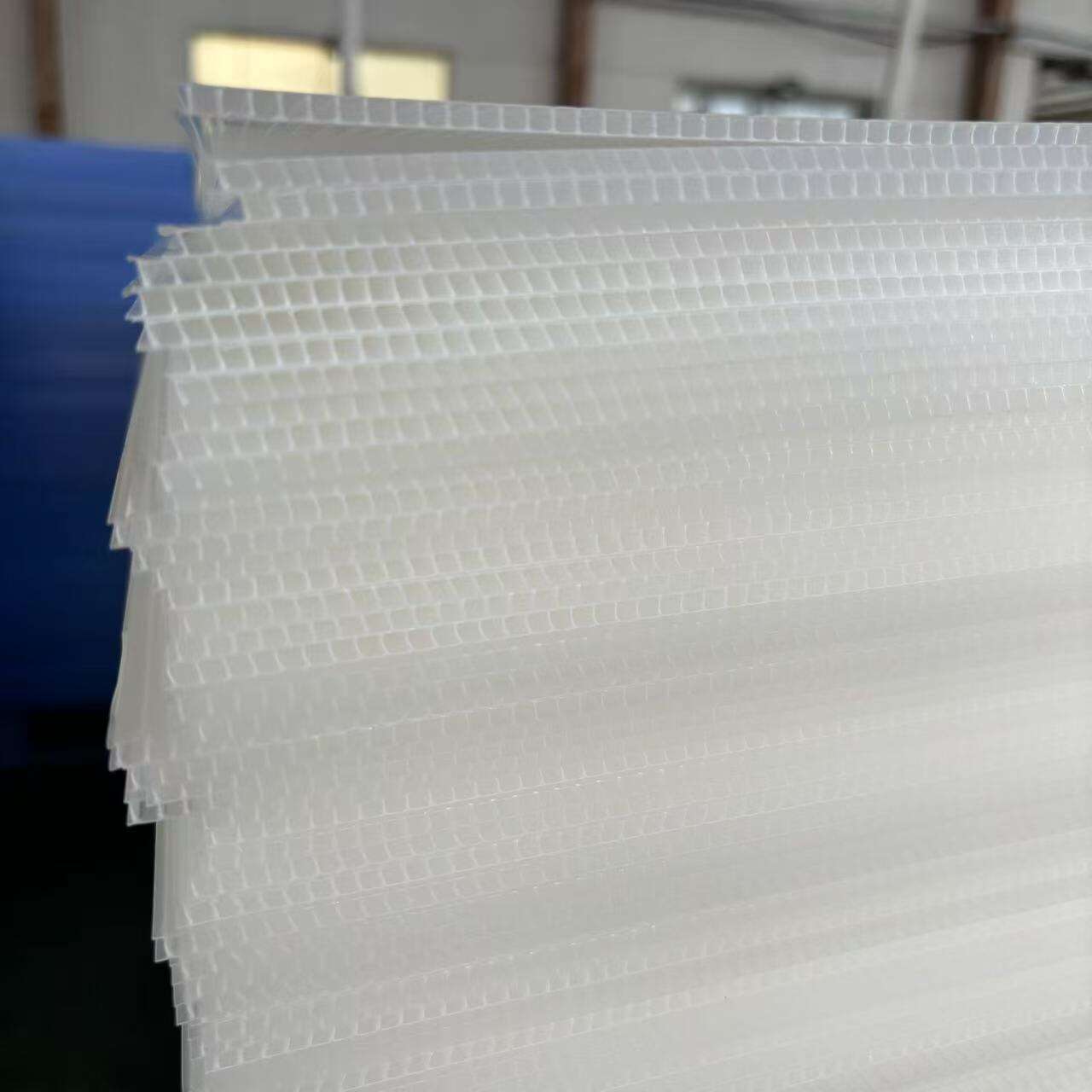

PP hollow sheet price represents a crucial consideration in the construction and packaging industries, offering a cost-effective solution for various applications. These sheets, manufactured through an advanced extrusion process, feature a unique hollow core structure that provides exceptional strength while maintaining lightweight properties. The pricing typically varies based on thickness, ranging from 2mm to 12mm, and dimensions that can be customized according to specific requirements. The material composition includes high-quality polypropylene resin, ensuring durability and resistance to chemical exposure. Market prices fluctuate based on raw material costs, manufacturing processes, and order quantities, generally ranging from $2 to $8 per square meter. The sheets demonstrate remarkable versatility, finding applications in construction, advertising, packaging, and agricultural sectors. Their competitive pricing, combined with features like UV resistance, weather durability, and recyclability, makes them an economical choice for both industrial and commercial applications. The cost-effectiveness is further enhanced by their long service life and minimal maintenance requirements, providing excellent value for investment across various use cases.