pp hollow board

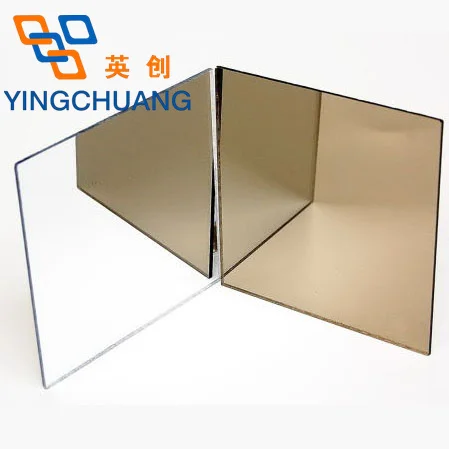

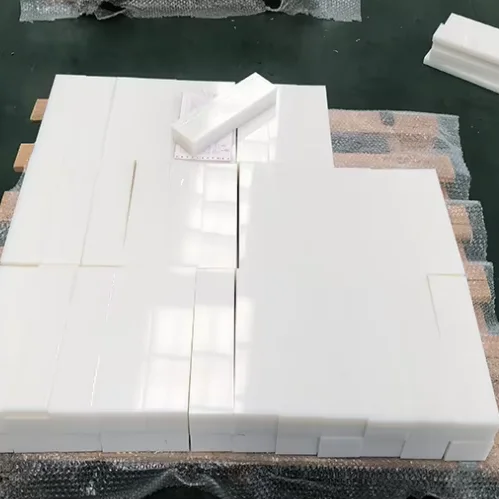

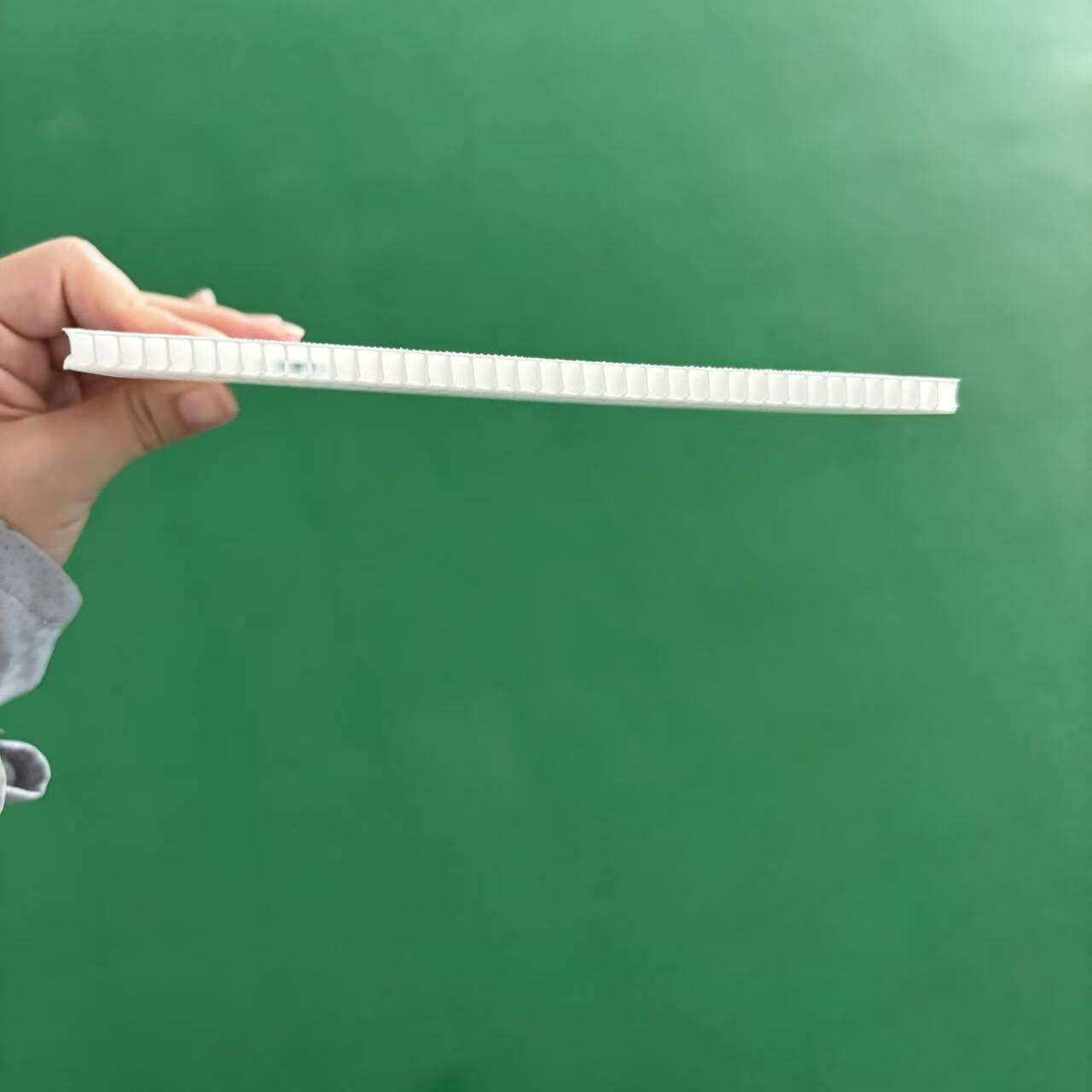

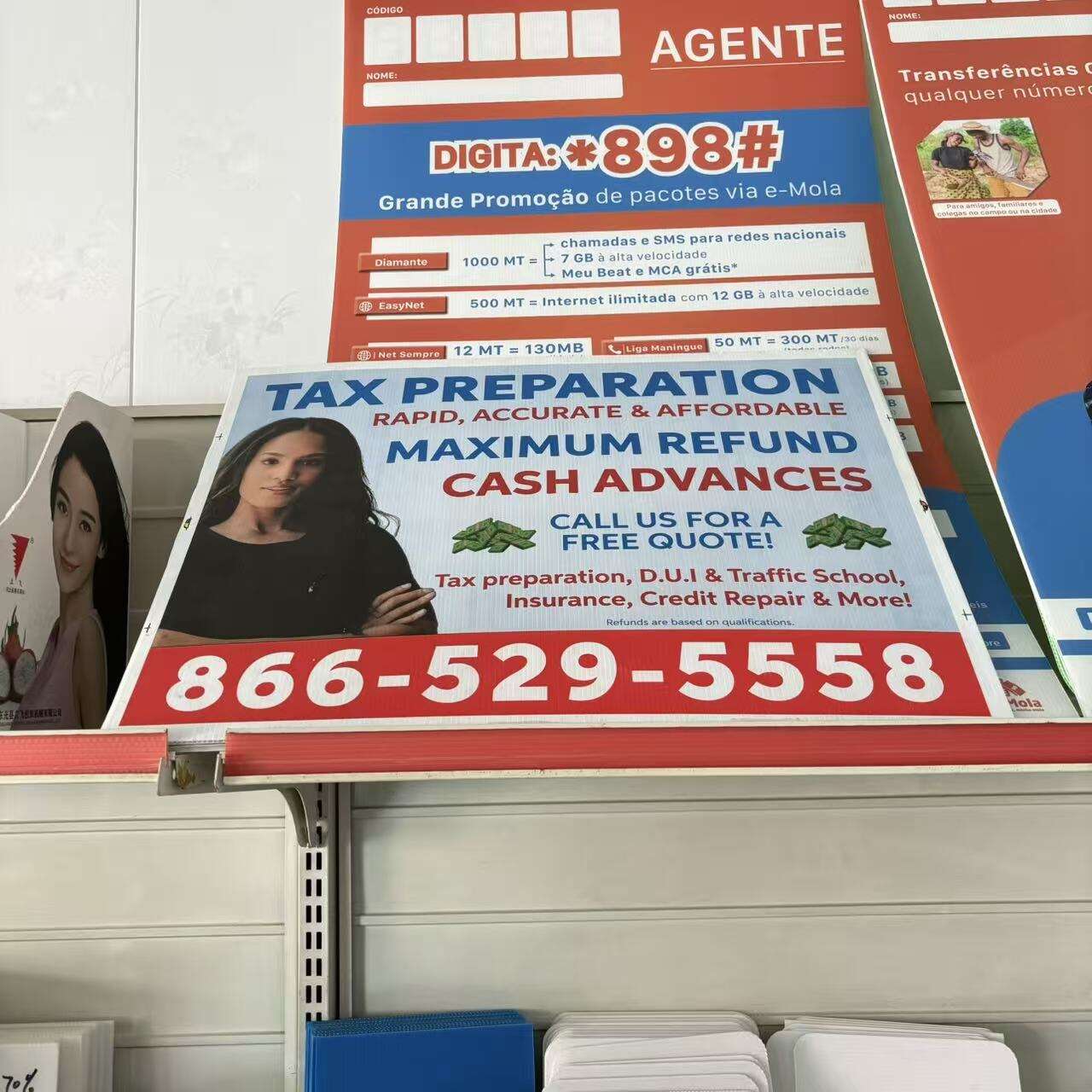

PP hollow board, also known as polypropylene corrugated sheet, represents a revolutionary advancement in sustainable packaging and construction materials. This versatile product features a unique multi-layer structure consisting of two outer flat layers and an inner corrugated core, all made from high-quality polypropylene. The distinctive design creates a lightweight yet remarkably strong material that offers superior protection and durability. The boards are manufactured through an advanced extrusion process that ensures consistent quality and structural integrity. What sets PP hollow board apart is its exceptional strength-to-weight ratio, making it an ideal choice for various applications across industries. The material's cellular structure provides excellent thermal insulation properties while maintaining structural rigidity. These boards are available in different thicknesses, colors, and surface treatments to meet specific application requirements. Their water-resistant nature and chemical stability make them suitable for both indoor and outdoor use. Additionally, the boards can be easily cut, folded, and fabricated using conventional tools, offering excellent workability for custom applications. The material's inherent recyclability aligns with modern sustainability requirements, making it an environmentally responsible choice for businesses looking to reduce their carbon footprint.