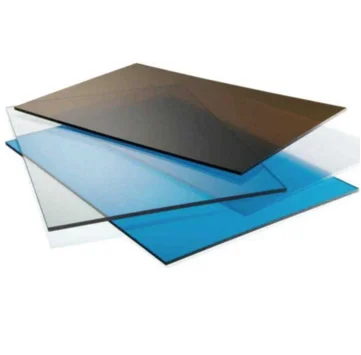

pp hollow sheet

PP hollow sheet, also known as polypropylene corrugated sheet, represents a versatile and innovative building material that has revolutionized various industries. This advanced material features a unique structure consisting of parallel channels or hollow cores running between two solid outer layers, creating a lightweight yet remarkably strong construction. The sheet's design incorporates advanced polymer technology that ensures superior durability while maintaining flexibility in application. These sheets typically range in thickness from 2mm to 12mm, offering varying degrees of strength and insulation properties. The manufacturing process involves co-extrusion technology, which allows for uniform thickness and consistent quality throughout the material. PP hollow sheets exhibit excellent chemical resistance, making them ideal for environments where exposure to harsh substances is common. They also demonstrate impressive thermal insulation properties, helping maintain stable temperatures in various applications. The material's UV resistance can be enhanced through additives during manufacturing, extending its outdoor lifespan. Notable features include its 100% recyclability, moisture resistance, and ability to withstand repeated impact without significant damage. These sheets find extensive use in packaging, construction, automotive parts, signage, and agricultural applications, demonstrating their versatility across multiple sectors.