Understanding Modern Mirror Solutions in Manufacturing

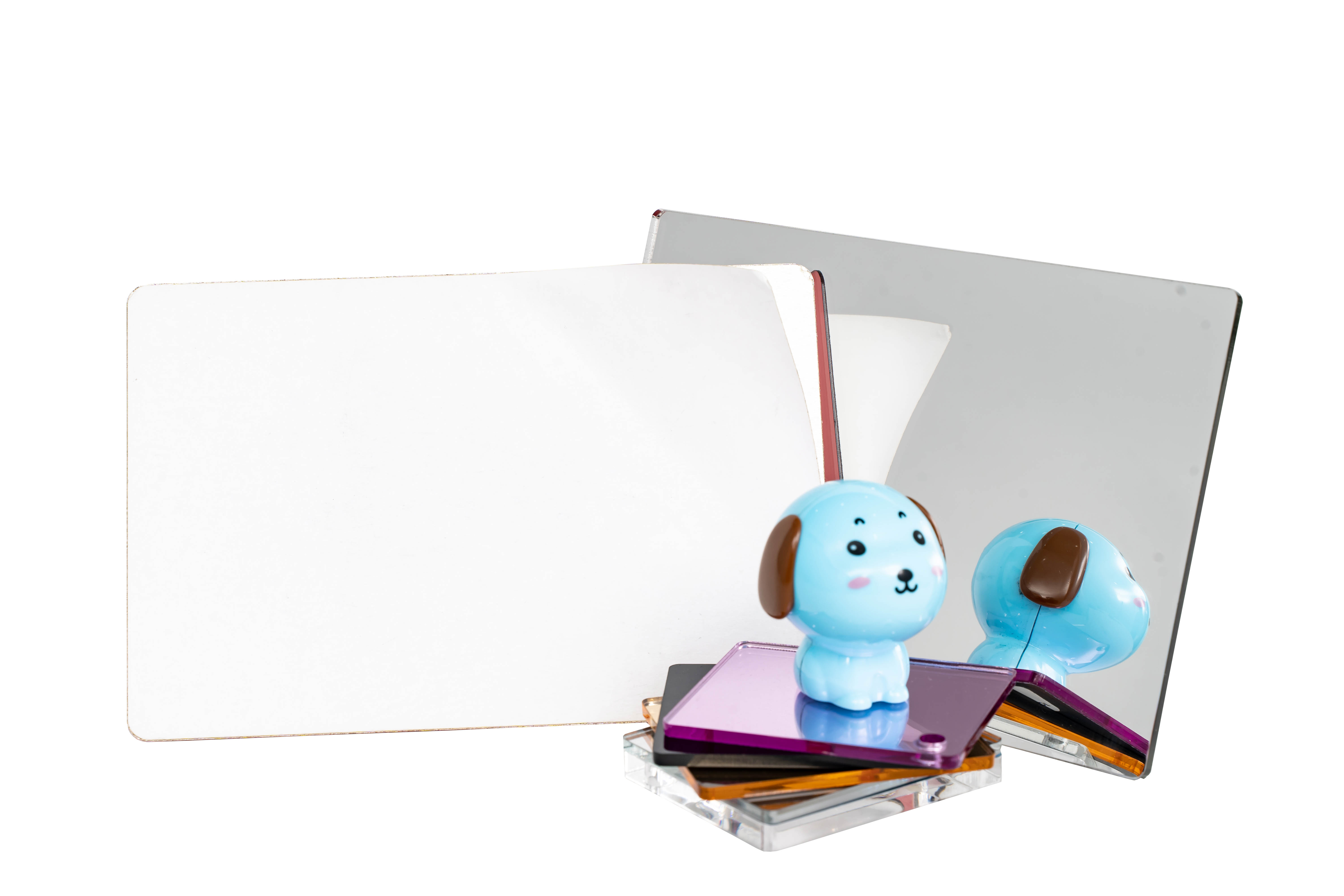

The evolution of mirror technology has brought us innovative materials that combine functionality with practicality. Among these advances, acrylic mirror sheet stands out as a versatile alternative to traditional glass mirrors. This lightweight, shatter-resistant material has revolutionized various industries, from interior design to safety applications, offering a perfect blend of aesthetics and durability.

As manufacturers and designers increasingly seek materials that provide both form and function, acrylic mirror sheet has emerged as a leading choice. Its unique combination of properties makes it suitable for diverse applications, from commercial spaces to residential projects, while maintaining cost-effectiveness and ease of installation.

Essential Properties of Acrylic Mirror Materials

Physical Characteristics and Durability

Acrylic mirror sheet possesses remarkable physical properties that set it apart from conventional mirror materials. At just half the weight of glass mirrors, these sheets offer superior handling and installation advantages. The material's inherent flexibility allows it to be curved or shaped without compromising its reflective properties, opening up possibilities for creative architectural applications.

The durability of acrylic mirror sheet is particularly noteworthy. Unlike glass mirrors, these sheets are highly impact-resistant and can withstand significant force without shattering. This makes them an excellent choice for high-traffic areas or locations where safety is a primary concern. Additionally, they maintain their appearance over time, resisting yellowing and degradation when properly maintained.

Optical Performance and Clarity

When it comes to optical qualities, acrylic mirror sheet delivers exceptional performance. The material offers up to 92% light reflectivity, creating bright and clear reflections that rival traditional glass mirrors. The surface maintains consistent reflectivity across its entire area, ensuring uniform appearance in all lighting conditions.

The optical clarity of these sheets is enhanced by their resistance to UV radiation, which helps prevent degradation of the reflective coating. This stability makes them suitable for both indoor and outdoor applications, maintaining their performance even under challenging environmental conditions.

Industrial and Commercial Applications

Retail Display Solutions

The retail industry has embraced acrylic mirror sheet as a versatile display solution. Store designers utilize these mirrors to create illusions of space, enhance product presentations, and improve overall shopping environments. The lightweight nature of the material allows for easy installation in ceiling displays, wall panels, and free-standing fixtures.

Visual merchandisers particularly appreciate the flexibility of acrylic mirror sheet in creating dynamic displays. The material can be cut to precise specifications, curved into attractive shapes, and integrated seamlessly with other display elements. This versatility enables retailers to refresh their store layouts frequently without the concerns associated with handling heavy glass mirrors.

Safety and Security Implementation

Security applications represent another significant use case for acrylic mirror sheet. Organizations implement these mirrors in surveillance systems, blind corner solutions, and security monitoring stations. The shatter-resistant properties make them ideal for environments where safety is paramount, such as schools, hospitals, and public facilities.

Transportation hubs and industrial facilities often install acrylic mirror sheets in areas with limited visibility to prevent accidents and improve overall safety. The durability of the material ensures long-term performance even in high-traffic areas, while its lightweight nature simplifies installation and maintenance procedures.

Design and Architectural Integration

Interior Design Applications

Interior designers increasingly turn to acrylic mirror sheet for innovative design solutions. The material's versatility allows for creative applications in residential and commercial spaces, from feature walls to decorative ceiling installations. Its lightweight nature enables designers to implement ambitious mirror designs that would be impractical with traditional glass.

The ability to customize acrylic mirror sheet through cutting, shaping, and even tinting opens up endless possibilities for unique interior features. Designers can create seamless mirror walls, sculptural elements, and integrated lighting solutions that transform spaces while maintaining practical functionality.

Exterior and Environmental Solutions

In exterior applications, acrylic mirror sheet proves its worth through weather resistance and durability. Landscape designers utilize these mirrors to create illusions of space in gardens and outdoor living areas, while architects incorporate them into building facades for both aesthetic and practical purposes.

The material's resistance to environmental factors makes it suitable for outdoor installations where traditional mirrors might deteriorate. From decorative garden features to practical safety applications in parking facilities, acrylic mirror sheet maintains its performance and appearance despite exposure to weather elements.

Installation and Maintenance Guidelines

Professional Installation Techniques

Successful installation of acrylic mirror sheet requires attention to specific techniques and considerations. Professional installers must account for thermal expansion, ensuring proper spacing and mounting methods to prevent warping or distortion. The use of appropriate adhesives and mounting hardware is crucial for long-term stability.

Installation procedures typically involve careful handling to prevent surface scratches, proper surface preparation, and the use of specialized cutting tools when required. Unlike glass mirrors, acrylic sheets can be modified on-site, though this should be done with appropriate tools and expertise to maintain the material's integrity.

Maintenance and Care Procedures

Maintaining acrylic mirror sheet requires different approaches compared to traditional glass mirrors. Regular cleaning with appropriate non-abrasive solutions helps preserve the surface quality and reflective properties. Avoiding harsh chemicals and abrasive cleaning tools prevents damage to the acrylic surface.

Long-term care includes periodic inspection for any signs of stress or damage, particularly in high-traffic areas or outdoor installations. Proper maintenance procedures extend the life of the installation while maintaining optimal performance and appearance.

Frequently Asked Questions

How does acrylic mirror sheet compare to traditional glass mirrors in terms of durability?

Acrylic mirror sheet offers superior impact resistance and is significantly less likely to shatter compared to glass mirrors. While it may be more susceptible to surface scratches, its overall durability and safety features make it an excellent choice for many applications where traditional glass mirrors might pose risks.

Can acrylic mirror sheet be used outdoors?

Yes, acrylic mirror sheet is suitable for outdoor applications due to its UV resistance and weather durability. However, proper installation and maintenance are crucial for optimal performance in exterior environments. The material should be mounted with appropriate consideration for thermal expansion and weather exposure.

What are the best cleaning methods for acrylic mirror sheet?

Clean acrylic mirror sheet using mild soap and water with a soft, non-abrasive cloth. Avoid harsh chemicals, window cleaners, or abrasive materials that could damage the surface. For stubborn marks, use specialized acrylic cleaners recommended by the manufacturer. Always pat dry with a clean, soft cloth to prevent streaking.