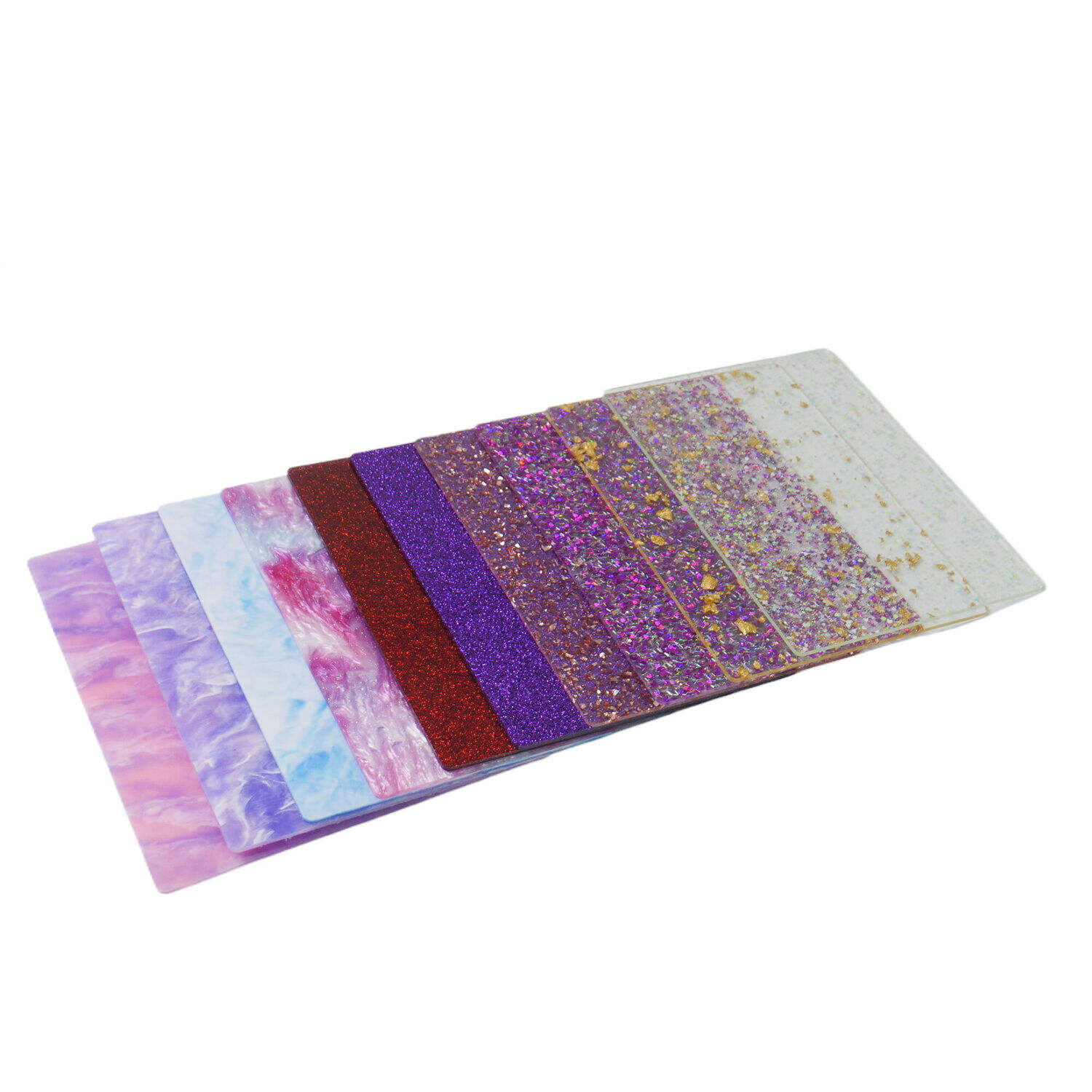

Working with decorative acrylic materials requires precision and proper techniques to achieve professional results. Glitter acrylic sheet has become increasingly popular in commercial and residential applications due to its stunning visual appeal and versatility. Understanding the correct cutting and shaping methods will ensure clean edges, prevent cracking, and maintain the material's sparkling properties throughout your project.

Essential Tools and Equipment for Cutting Glitter Acrylic

Power Tools for Precision Cutting

Selecting the right power tools significantly impacts the quality of your finished project when working with glitter acrylic sheet. A circular saw equipped with a fine-tooth blade designed for plastics delivers clean, straight cuts without chipping. The blade should have at least 80 teeth per 10-inch diameter to minimize heat buildup and prevent melting along the cut line. Maintain a steady feed rate to avoid overheating the material.

Table saws offer excellent control for larger sheets and repetitive cuts. Install a triple-chip grind blade with carbide tips to handle the abrasive nature of glitter particles embedded within the acrylic. Keep the blade height just above the material thickness to reduce tear-out on the exit side. A zero-clearance insert helps prevent small pieces from falling through the table opening.

Hand Tools and Manual Cutting Methods

Hand tools provide excellent control for detailed work and smaller pieces of glitter acrylic sheet. A scoring knife with a sharp blade creates precise score lines for snap-cutting thin sheets up to 3mm thickness. Apply firm, consistent pressure in a single pass to avoid multiple score marks that weaken the material. Follow the score line with steady downward pressure to achieve a clean break.

Fine-tooth handsaws work effectively for curved cuts and intricate shapes. Choose saws with 18-24 teeth per inch to minimize chipping around glitter particles. Support the material properly during cutting to prevent flexing that could cause stress cracks. Maintain a consistent cutting angle and use light pressure to let the blade do the work.

Preparation and Safety Considerations

Workspace Setup and Material Handling

Proper preparation ensures successful results when cutting glitter acrylic sheet materials. Clean your workspace thoroughly to remove any debris that could scratch the surface during handling. Use padded supports or blankets to protect the decorative surface from contact marks. Ensure adequate lighting to clearly see cut lines and potential defects in the material.

Temperature control affects the cutting performance of acrylic materials. Room temperature between 68-72°F provides optimal conditions for clean cuts without thermal stress. Avoid cutting in direct sunlight or near heat sources that could cause thermal expansion. Allow materials stored in cold environments to reach room temperature before cutting to prevent brittleness.

Personal Protection and Safety Protocols

Safety equipment protects against potential hazards when working with glitter acrylic sheet and power tools. Safety glasses with side shields prevent glitter particles and acrylic chips from reaching your eyes. Dust masks filter airborne particles created during cutting operations. Hearing protection reduces noise exposure from power tools during extended work sessions.

Secure workpieces properly using clamps or fixtures to prevent movement during cutting. Never attempt to hold small pieces by hand when using power tools. Keep fingers away from blade paths and maintain proper body positioning to avoid injury if tools slip or bind. Disconnect power tools when changing blades or making adjustments.

Cutting Techniques for Different Thicknesses

Thin Sheet Processing Methods

Thin glitter acrylic sheet materials between 1-3mm thickness respond well to score-and-snap cutting methods. Mark your cut line clearly using a straightedge and fine-tip marker. Position the material with the cut line extending slightly over the edge of your work surface. Apply steady pressure with a scoring knife to create a uniform groove approximately one-third through the material thickness.

Support both sides of the scored line when applying breaking pressure to prevent uneven fractures. Apply downward pressure in one smooth motion rather than repeatedly bending the material. The break should follow the score line precisely, creating a clean edge suitable for most applications. Light sanding with fine-grit paper removes any minor irregularities.

Medium and Thick Sheet Cutting Approaches

Thicker glitter acrylic sheet materials require power tools for effective cutting. Sheets between 4-10mm thickness cut best with circular saws or jigsaws equipped with appropriate blades. Feed the material slowly to prevent overheating and melting along the cut edge. Use cutting fluid or compressed air to remove chips and cool the cutting area during operation.

Router cutting provides excellent edge quality for thick materials when precision matters. Use straight-flute bits designed for plastics and maintain moderate spindle speeds to avoid heat buildup. Multiple passes at increasing depths produce better results than attempting full-depth cuts in single passes. Climb cutting helps prevent chip-out on the exit side of through cuts.

Shaping and Forming Techniques

Heat Forming and Thermoforming Methods

Heat forming allows glitter acrylic sheet materials to be shaped into curved or complex forms while maintaining structural integrity. Preheat forming ovens to 280-320°F depending on material thickness and desired bend radius. Thicker sheets require higher temperatures and longer heating times to achieve uniform plasticity throughout the cross-section.

Create forming fixtures from heat-resistant materials like aluminum or steel to maintain dimensional accuracy during cooling. Support the heated material evenly to prevent sagging or distortion in unsupported areas. Work quickly once the material reaches forming temperature, as the working window closes rapidly as cooling begins. Allow gradual cooling to room temperature to minimize internal stresses.

Cold Forming and Mechanical Shaping

Cold forming techniques work effectively for gentle curves and gradual bends in glitter acrylic sheet materials. Strip heaters concentrate heat along narrow bend lines without heating entire sheets. Position the bend line directly over the heating element and wait for the material to become pliable before applying bending force.

Mechanical forming uses jigs and fixtures to shape materials without heat application. This method works best for materials under 3mm thickness where flexibility allows bending without cracking. Apply pressure gradually and monitor for stress whitening that indicates excessive strain. Release pressure if whitening appears and consider alternative forming methods.

Edge Finishing and Surface Treatment

Edge Polishing and Smoothing Methods

Professional edge finishing enhances the appearance and safety of cut glitter acrylic sheet pieces. Begin with coarse sandpaper (220-320 grit) to remove saw marks and major irregularities. Progress through finer grits (400, 600, 800) to achieve increasingly smooth surfaces. Maintain consistent pressure and use circular motions to avoid creating directional scratches.

Flame polishing produces crystal-clear edges on thick acrylic materials when performed correctly. Use a clean torch flame and move steadily along the edge to avoid overheating any single area. The surface should become glossy without bubbling or distortion. Practice on scrap pieces before attempting flame polishing on finished projects.

Surface Protection and Maintenance

Protecting cut edges during assembly prevents damage to finished surfaces. Apply protective tape to polished edges before handling or installation. Remove tape carefully to avoid leaving adhesive residue that attracts dirt and debris. Clean surfaces with appropriate acrylic cleaners and lint-free cloths.

Storage conditions affect the longevity of finished glitter acrylic sheet components. Store pieces vertically when possible to prevent sagging under their own weight. Separate pieces with soft interleaving materials to prevent surface scratching. Avoid exposure to solvents or harsh chemicals that could damage the glitter coating or acrylic substrate.

Troubleshooting Common Issues

Preventing and Addressing Cracks

Stress cracks in glitter acrylic sheet materials typically result from improper cutting techniques or excessive force application. Dull blades create excessive heat and pressure that leads to internal stress concentration. Replace cutting blades regularly and maintain sharp edges for clean cuts. Reduce feed rates when cutting thick materials to minimize heat generation.

Environmental factors contribute to cracking problems in some installations. Rapid temperature changes cause thermal expansion and contraction that stresses the material. Design installations with appropriate expansion joints and flexible mounting systems. Avoid rigid mounting that prevents natural material movement with temperature variations.

Dealing with Glitter Particle Loss

Glitter particle displacement during cutting operations affects the visual appearance of finished edges. Sharp cutting blades minimize particle disruption by creating clean cuts rather than tearing through the material. Support the glitter acrylic sheet properly during cutting to prevent flexing that loosens embedded particles.

Edge sealing techniques help secure loose glitter particles after cutting operations. Clear acrylic paint or specialized edge sealers provide protective barriers over cut edges. Apply thin, even coats and allow proper curing time between applications. Test sealing products on scrap pieces to ensure compatibility with your specific material formulation.

FAQ

What blade type works best for cutting thick glitter acrylic sheet

Triple-chip grind carbide blades with 80+ teeth per 10-inch diameter provide optimal results for thick glitter acrylic materials. These specialized blades minimize heat buildup while handling the abrasive nature of embedded glitter particles. Maintain moderate feed rates to prevent overheating and melting along cut lines.

Can I use regular woodworking tools on glitter acrylic sheet

Standard woodworking tools can be adapted for glitter acrylic cutting with proper blade selection and technique modifications. Replace wood-cutting blades with plastic-specific versions featuring finer teeth and different rake angles. Reduce cutting speeds and feed rates compared to wood cutting applications to prevent heat damage.

How do I prevent melting when cutting glitter acrylic sheet

Preventing melting requires proper blade selection, appropriate cutting speeds, and effective heat management. Use sharp blades designed for plastics and maintain moderate cutting speeds to minimize friction heating. Apply cutting lubricants or compressed air cooling to remove heat and chips from the cutting area during operation.

What thickness of glitter acrylic sheet can be score-and-snap cut

Score-and-snap cutting works effectively on glitter acrylic sheet materials up to 3mm thickness under ideal conditions. Thinner materials (1-2mm) snap more reliably with clean breaks following score lines. Thicker materials may require multiple scoring passes or alternative cutting methods to achieve satisfactory results without cracking.