high impact polystyrene sheet suppliers

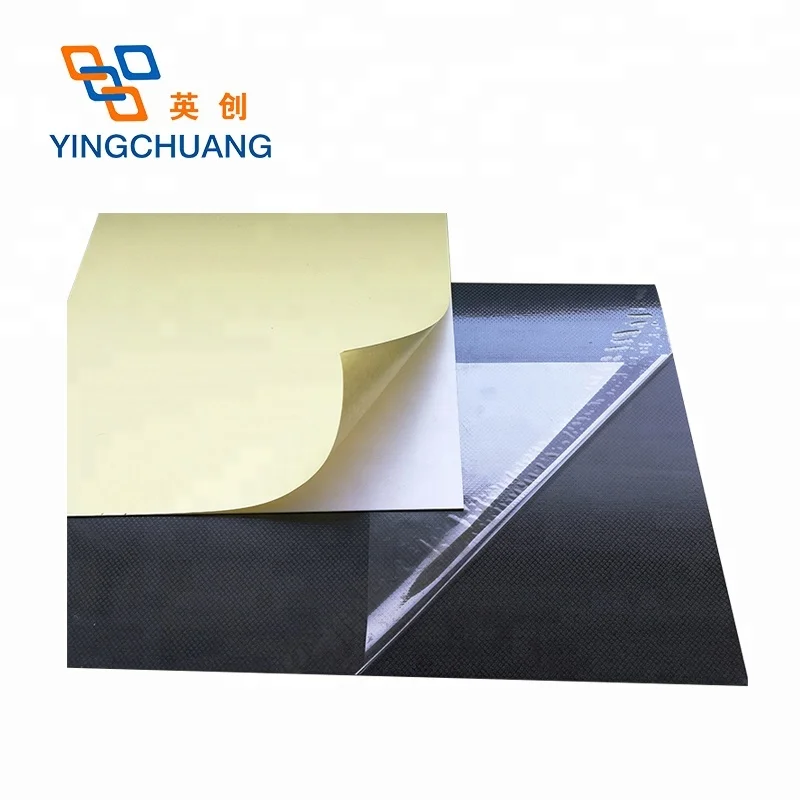

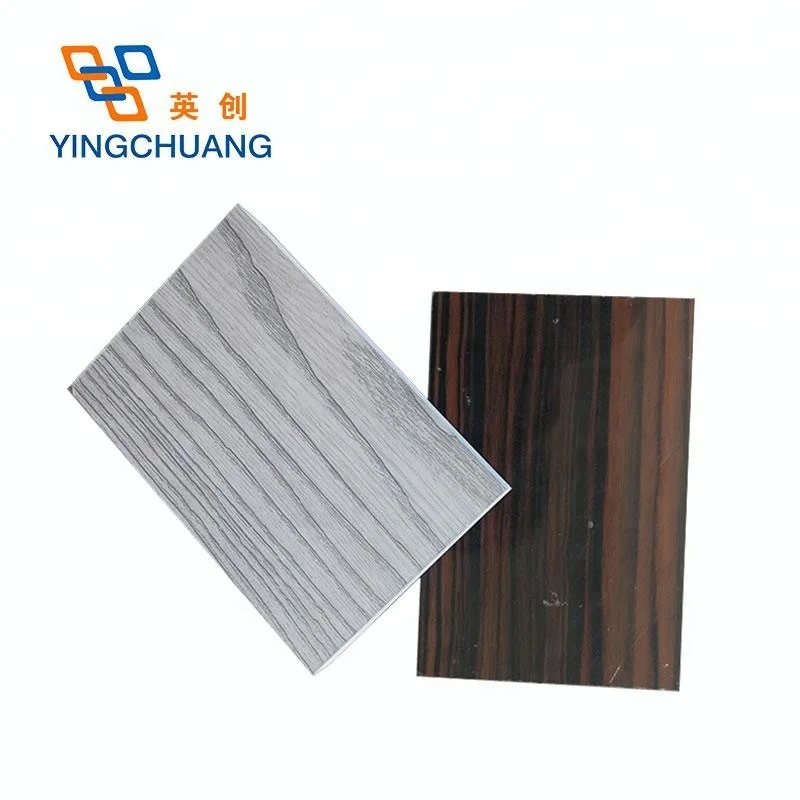

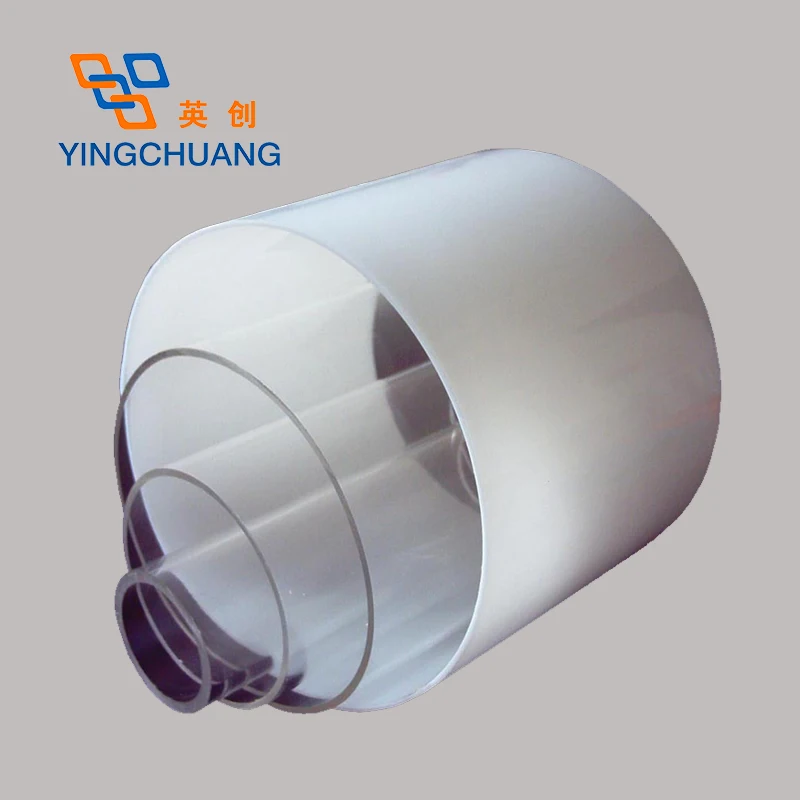

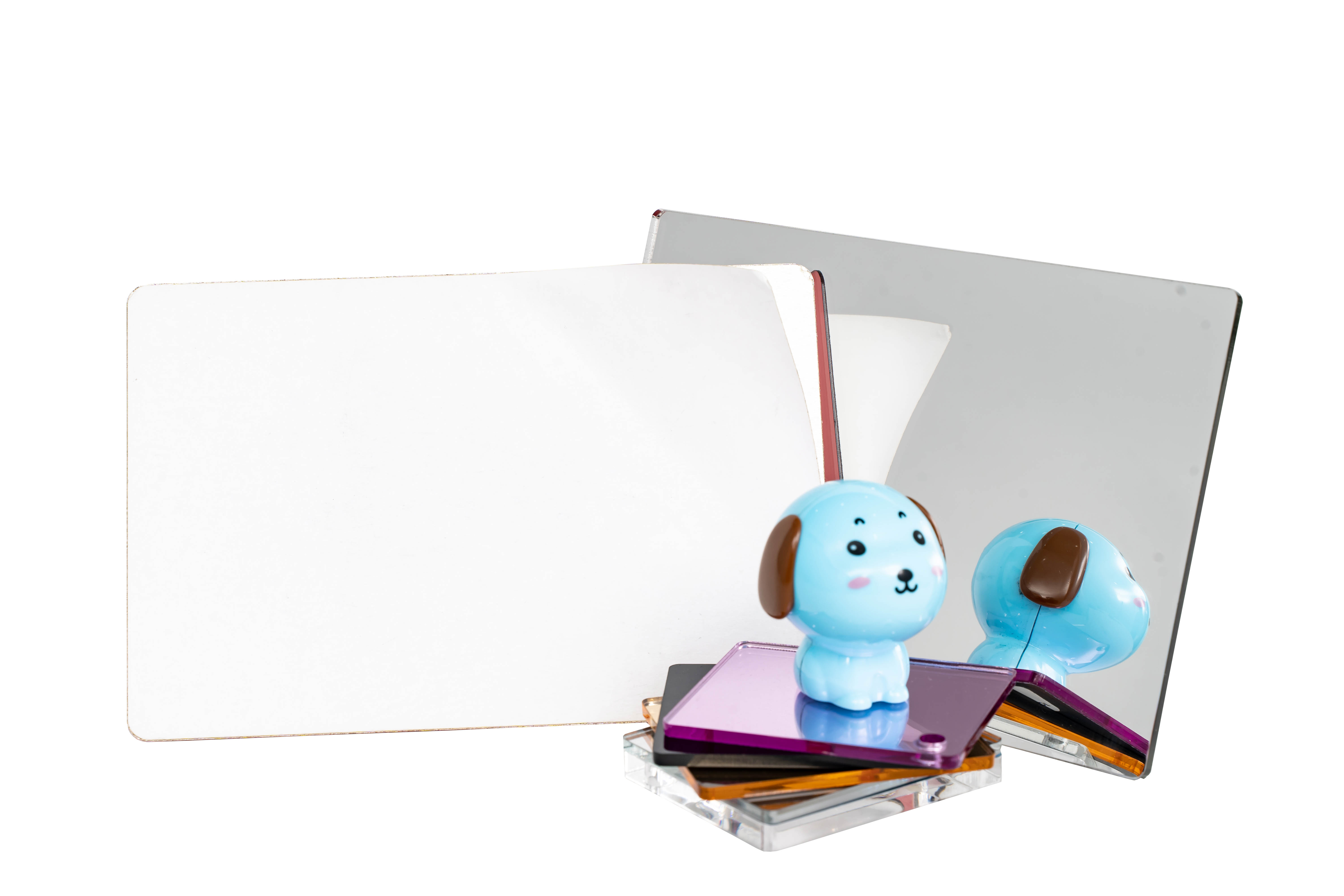

High impact polystyrene (HIPS) sheet suppliers play a crucial role in providing essential materials for various industries. These suppliers specialize in manufacturing and distributing robust, versatile plastic sheets that combine the rigidity of regular polystyrene with enhanced impact resistance. The suppliers ensure consistent quality through advanced production processes, offering sheets in various thicknesses, sizes, and colors to meet diverse customer requirements. Their products undergo rigorous quality control measures, including impact resistance testing, dimensional stability checks, and surface quality assessments. Modern HIPS sheet suppliers utilize state-of-the-art extrusion technology to produce sheets with excellent thermoforming capabilities, making them ideal for packaging, point-of-purchase displays, and consumer goods applications. They maintain extensive inventory systems and efficient distribution networks to ensure prompt delivery and reliable supply chain management. Many suppliers also provide custom solutions, including cut-to-size services, specialty colors, and texture options. These suppliers serve numerous sectors, including packaging, automotive, medical device manufacturing, and consumer electronics, offering technical support and material selection guidance to optimize product performance for specific applications.