coloured polystyrene sheets

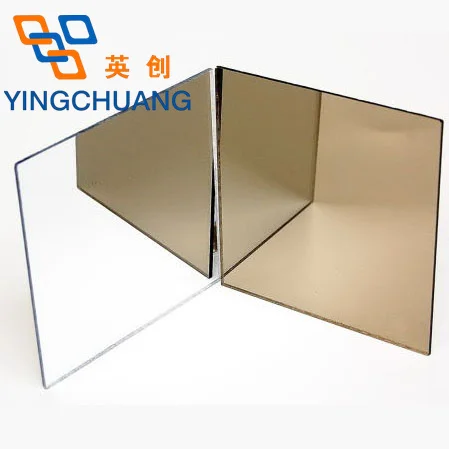

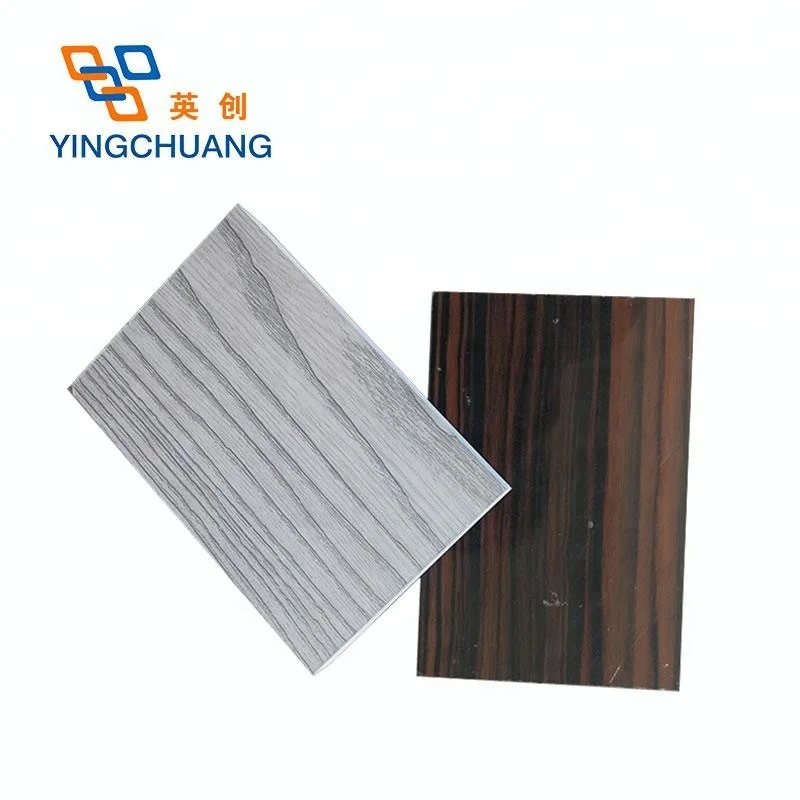

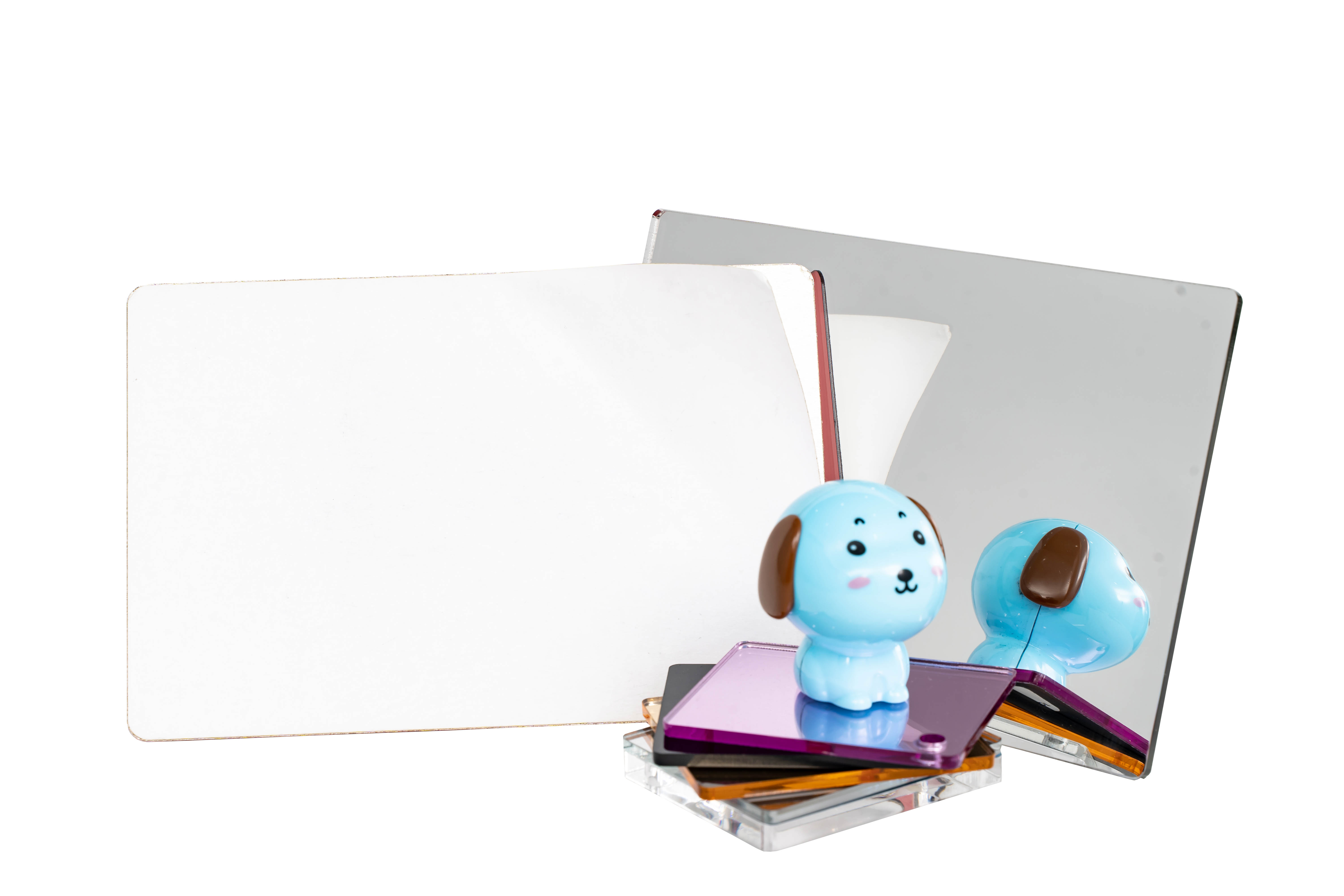

Coloured polystyrene sheets represent a versatile and innovative material solution that combines aesthetic appeal with practical functionality. These sheets are manufactured through an advanced extrusion process that incorporates high-quality pigments directly into the polystyrene material, ensuring consistent coloration throughout the entire sheet. Available in a wide spectrum of colors and thicknesses ranging from 1mm to 5mm, these sheets offer exceptional durability and dimensional stability. The material features excellent impact resistance and maintains its vibrant appearance even after prolonged exposure to indoor lighting conditions. The sheets can be easily fabricated using standard tools and techniques, including cutting, drilling, and thermoforming, making them highly adaptable for various applications. They are particularly valued in the signage industry, retail displays, and architectural applications where both visual appeal and structural integrity are essential. The sheets also demonstrate remarkable resistance to moisture and many common chemicals, making them suitable for both indoor and protected outdoor applications. Their lightweight nature, combined with high rigidity, makes them an ideal choice for projects requiring both strength and ease of handling.