high density polystyrene sheets

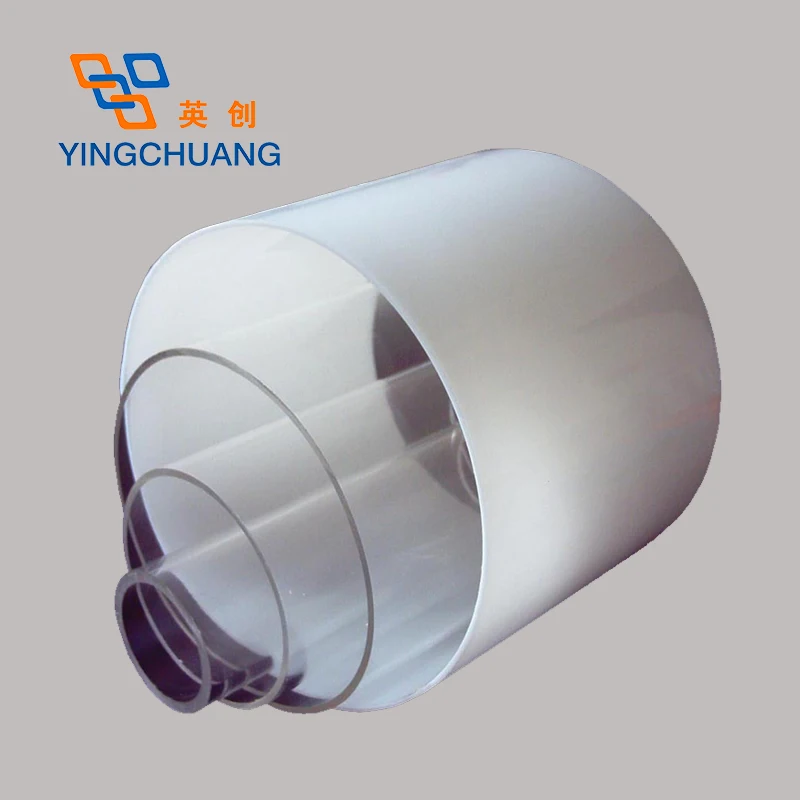

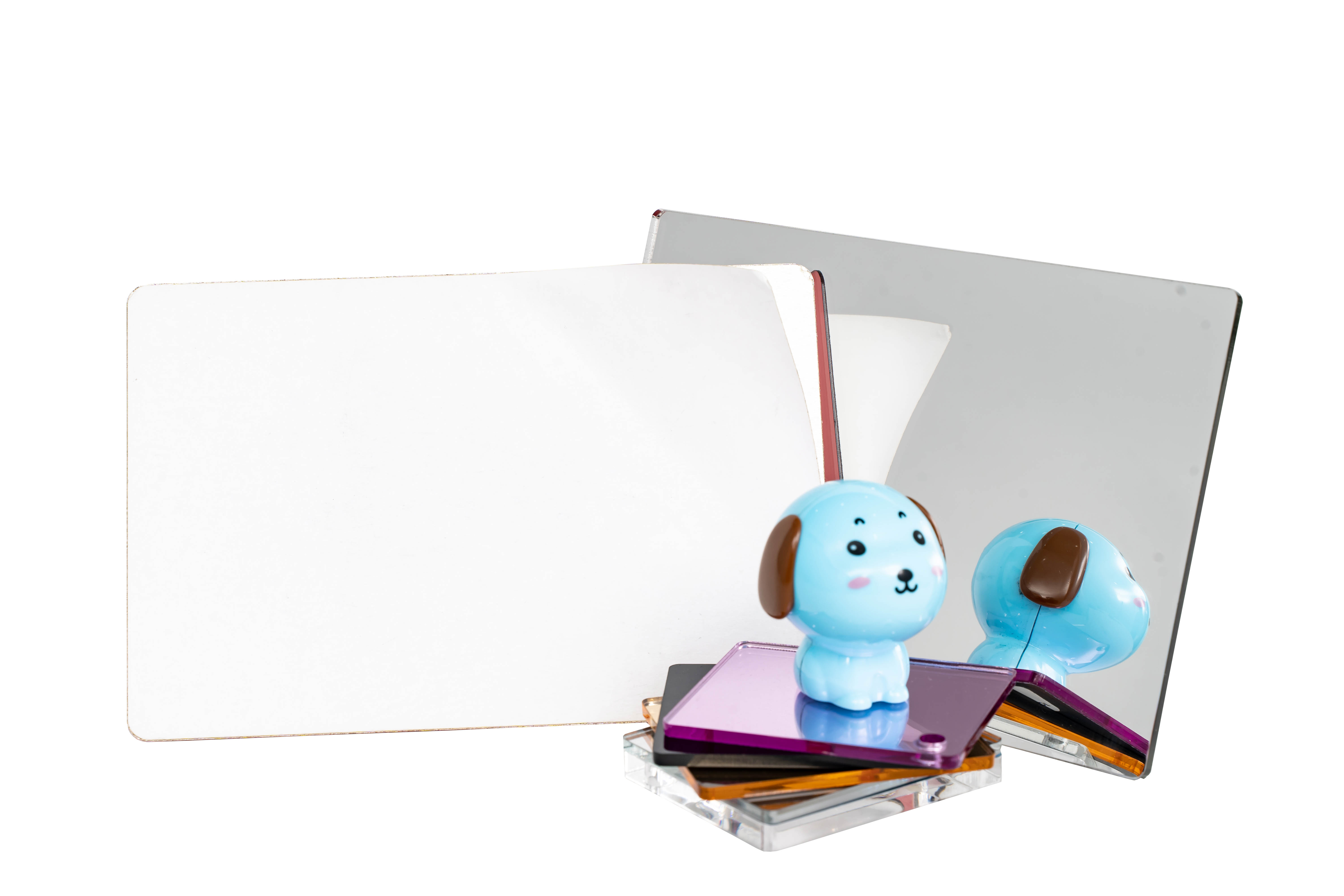

High density polystyrene sheets represent a versatile and robust material solution widely utilized across various industries. These sheets are manufactured through an advanced extrusion process that creates a dense, uniform structure with exceptional strength-to-weight characteristics. The material exhibits superior impact resistance and dimensional stability, making it ideal for both protective packaging and structural applications. With densities typically ranging from 40 to 60 pounds per cubic foot, these sheets offer remarkable durability while maintaining relatively light weight. The sheets can be easily fabricated, thermoformed, and modified to meet specific application requirements. They feature excellent moisture resistance and maintain their structural integrity across a wide temperature range. In industrial applications, high density polystyrene sheets serve as reliable components in construction, signage, and protective packaging. The material's smooth surface finish and consistent thickness make it particularly suitable for printing and display applications. Additionally, these sheets demonstrate good chemical resistance to many common substances, enhancing their versatility in various environmental conditions. Their closed-cell structure prevents water absorption, making them ideal for outdoor applications and moisture-sensitive environments.