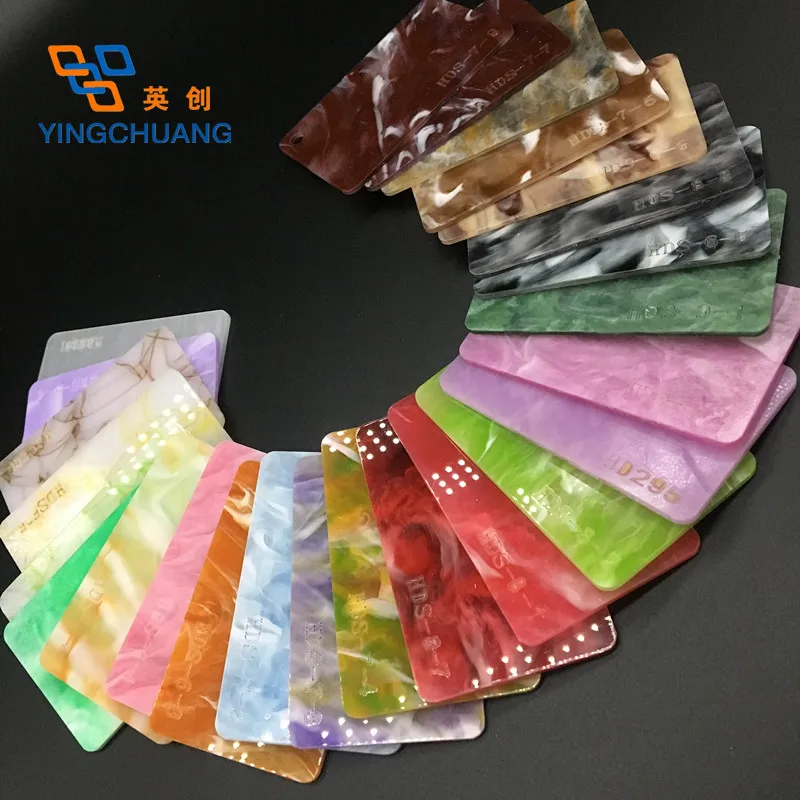

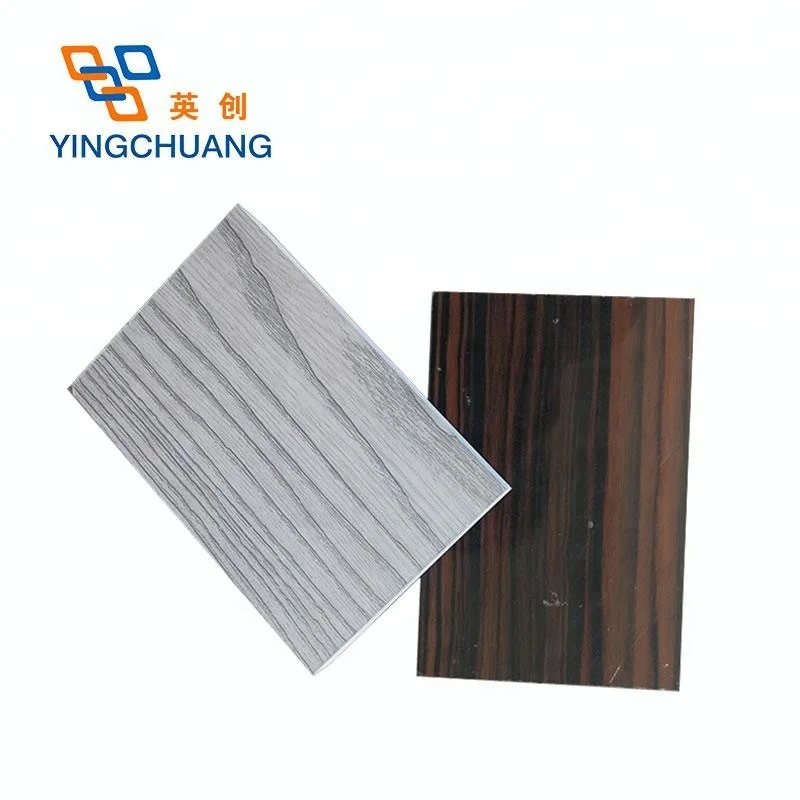

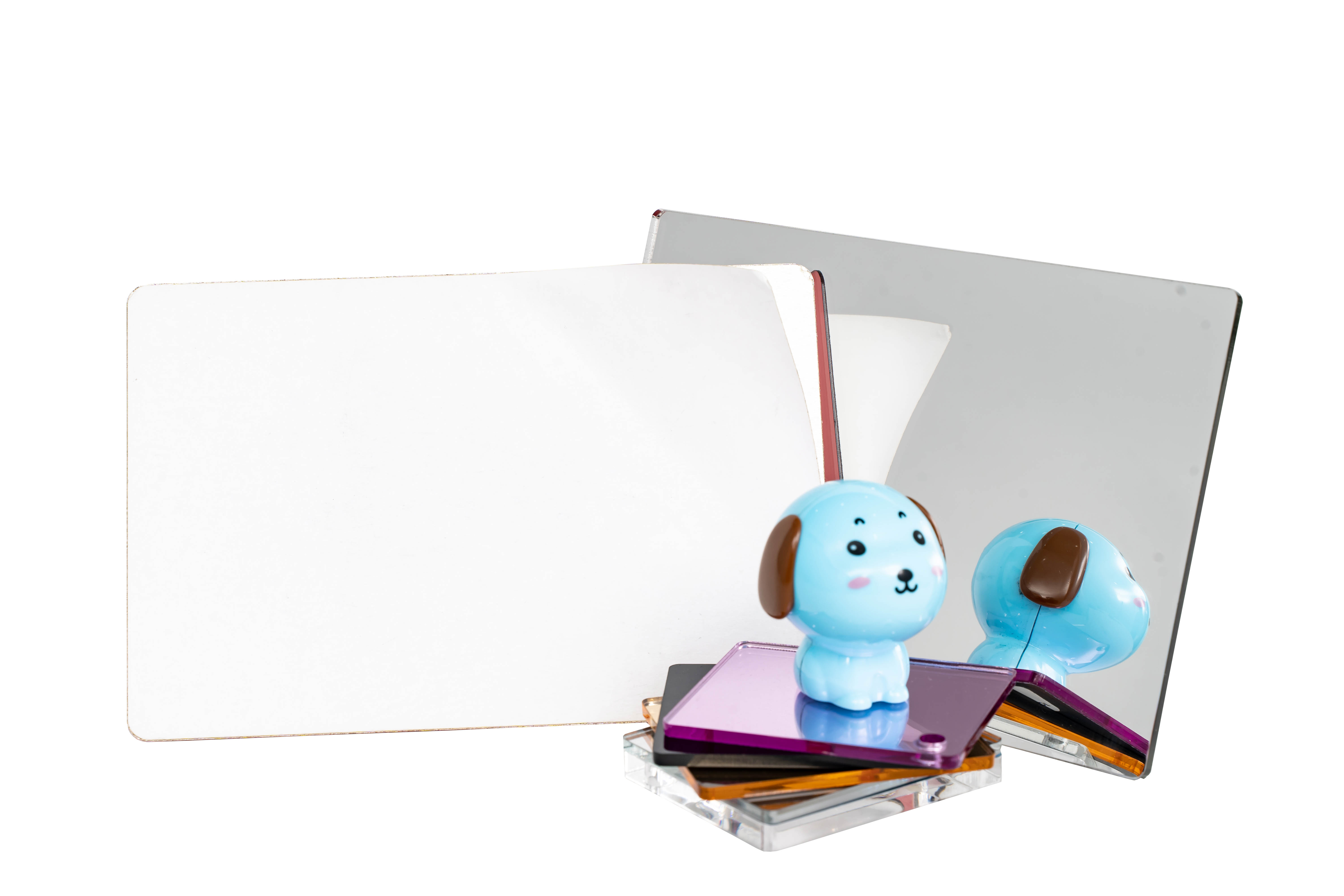

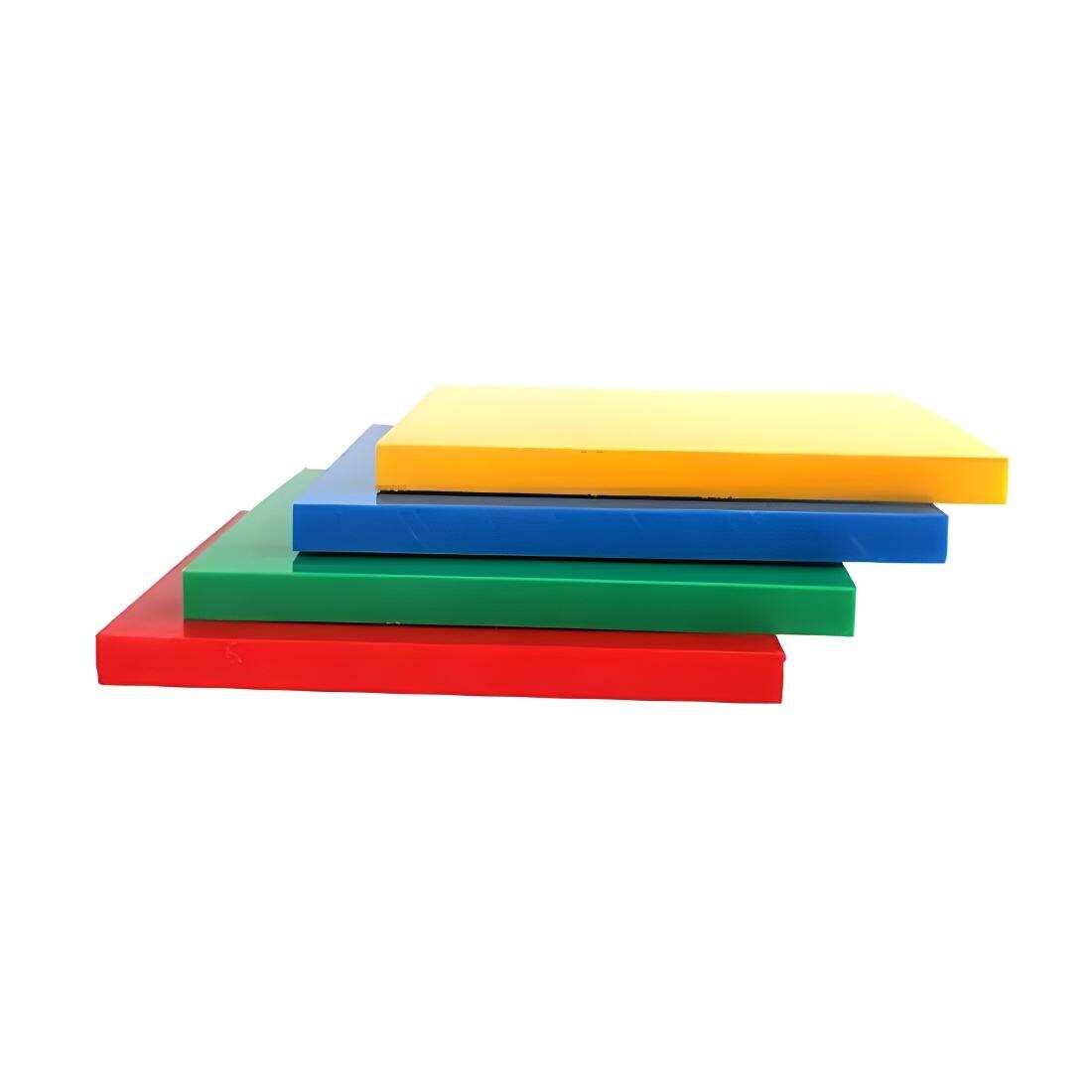

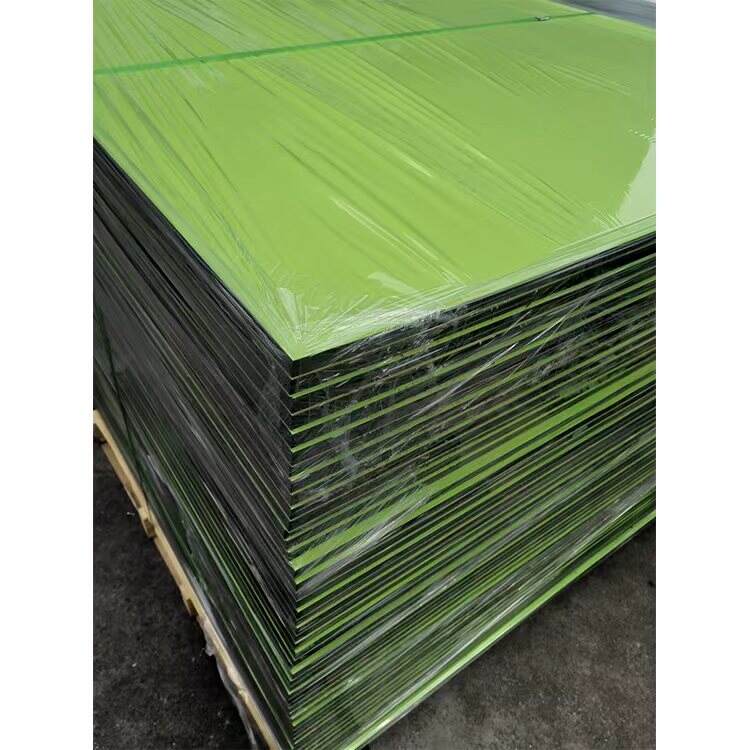

custom hdpe sheets

Custom HDPE sheets represent a versatile and robust material solution in modern manufacturing and construction. These high-density polyethylene sheets are engineered to exact specifications, offering exceptional durability and chemical resistance. The manufacturing process involves careful molecular structuring, resulting in sheets that maintain their integrity across diverse environmental conditions. These custom sheets can be fabricated in various thicknesses, sizes, and colors to meet specific project requirements. The material's inherent properties include excellent impact resistance, low moisture absorption, and outstanding UV stability, making it ideal for both indoor and outdoor applications. HDPE sheets demonstrate remarkable flexibility in processing, allowing for cutting, welding, and thermoforming operations. They maintain structural stability across a wide temperature range, from -148°F to 180°F, and resist corrosion from most chemicals. Industries ranging from construction to food processing rely on these sheets for their superior performance characteristics and long service life.