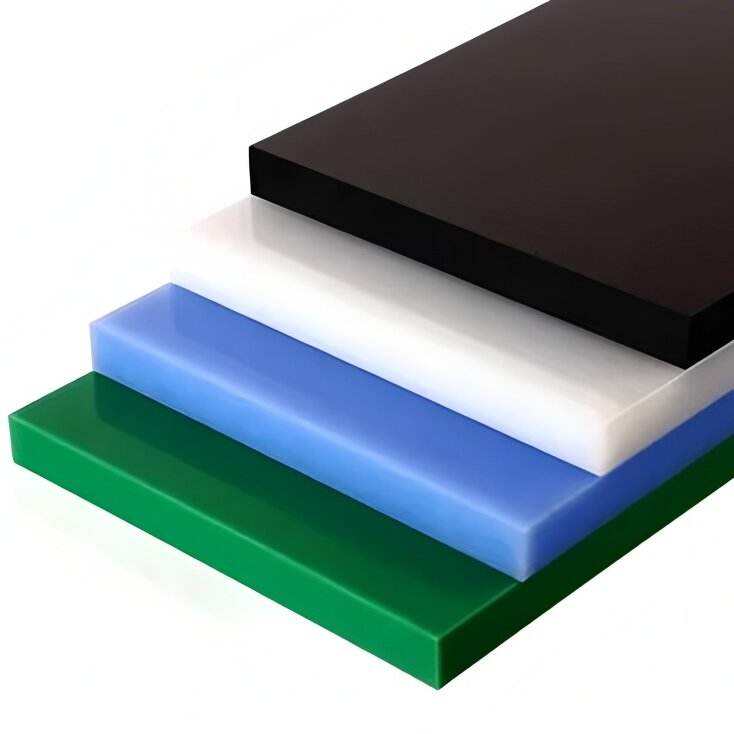

Superior Chemical and Environmental Resistance

Flexible HDPE sheets excel in their remarkable resistance to chemical exposure and environmental factors. The material's molecular structure provides exceptional protection against a wide range of chemicals, including acids, bases, oils, and industrial solvents. This inherent resistance makes these sheets ideal for containing hazardous materials and protecting surfaces in chemical processing facilities. The sheets maintain their structural integrity even when exposed to harsh weather conditions, including extreme temperatures, UV radiation, and moisture. Their resistance to environmental degradation ensures a longer service life compared to traditional materials, reducing replacement frequency and associated costs. The material's ability to withstand both chemical and environmental challenges makes it particularly valuable in outdoor applications, industrial settings, and areas with high exposure to corrosive substances.