HIPS Sheet - High Impact Polystyrene Plastic Sheet for Fabrication & Modeling

HIPS (High Impact Polystyrene) Sheet is a versatile, economical, and user-friendly thermoplastic known for its excellent impact strength and ease of fabrication. This rigid plastic sheet is a preferred choice for a wide range of applications, from professional vacuum forming and packaging to hobbyist model making and signage. Its balanced properties provide an ideal combination of durability and workability, making it a staple in workshops and factories alike.

- Overview

- Recommended Products

HIPS (High Impact Polystyrene) Sheet is a versatile, economical, and user-friendly thermoplastic known for its excellent impact strength and ease of fabrication. This rigid plastic sheet is a preferred choice for a wide range of applications, from professional vacuum forming and packaging to hobbyist model making and signage. Its balanced properties provide an ideal combination of durability and workability, making it a staple in workshops and factories alike.

|

|

|

|

|

|

|

|

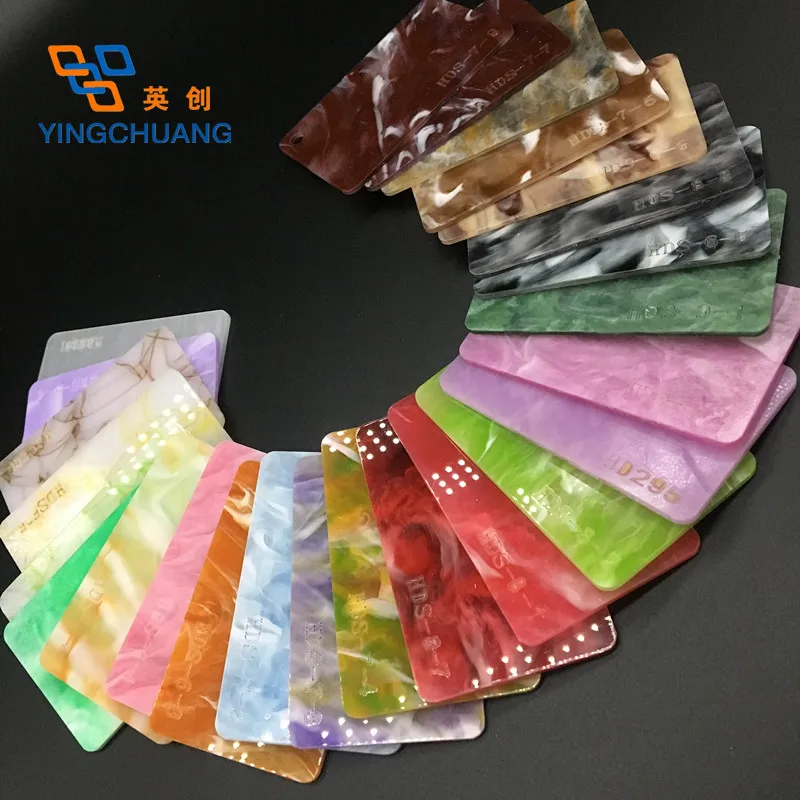

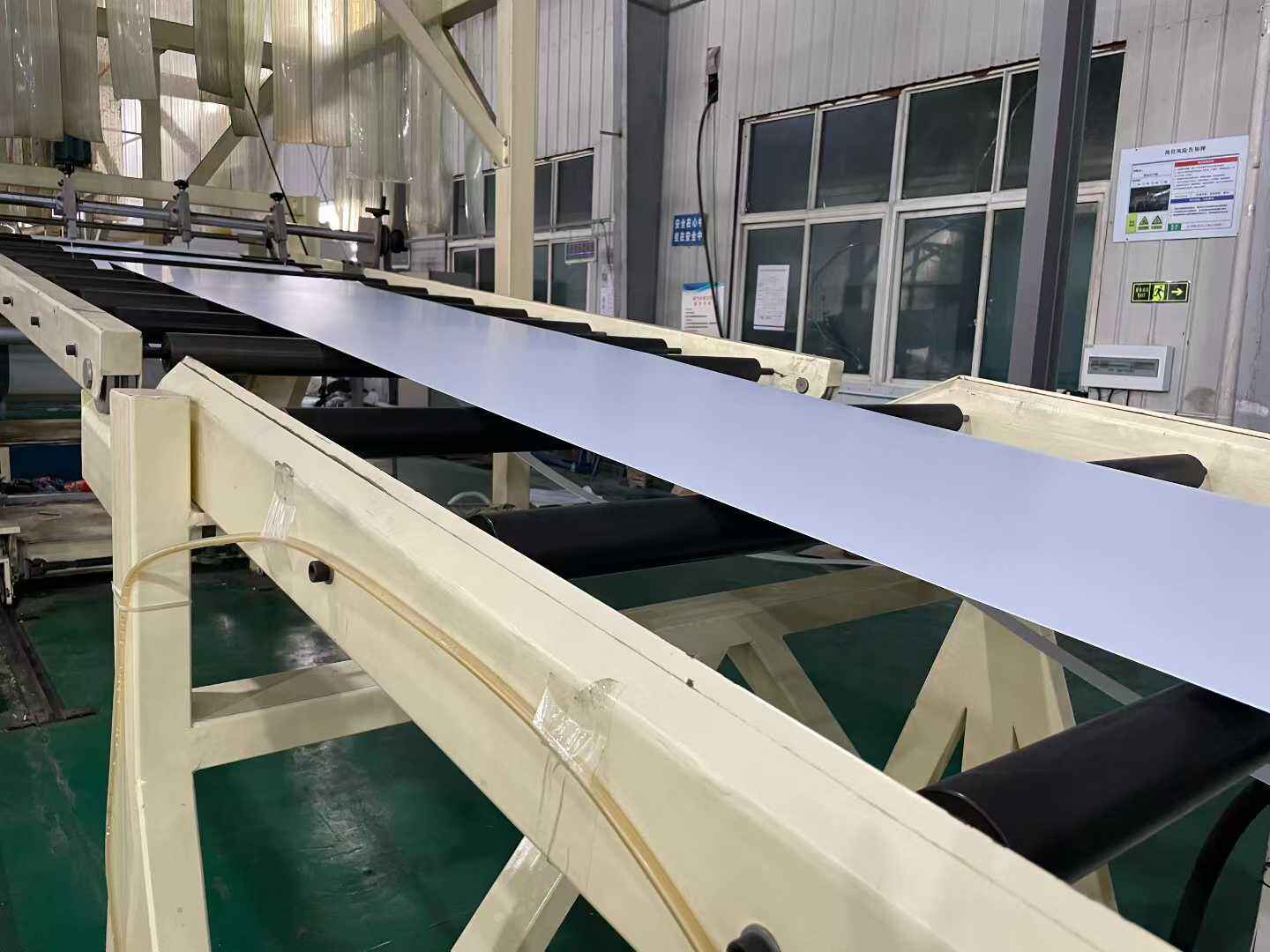

| Specifications: | Place of Origin: China |

| Brand Name: YINGCHUANG | |

| Thickness: 2mm to 10mm. | |

| Width: 1220mm, 1560mm, 2050mm, etc. | |

| Length: Customizable based on actual needs, 2440mm being common. |

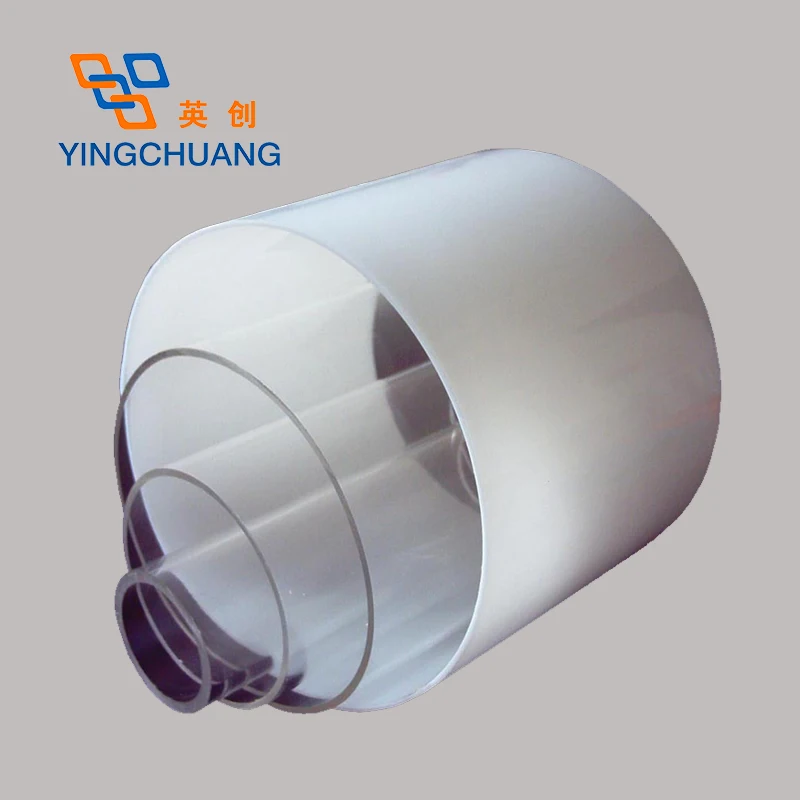

Vacuum Forming: Perfect for creating prototypes, product packaging, clamshells, and automotive interior components.

Signage & Displays: Used for indoor signs, point-of-purchase (POP) displays, and exhibition boards due to its excellent printability.

Model Making & Prototyping: A favorite among hobbyists and engineers for creating architectural models, RC airplane parts, and functional prototypes.

Packaging: Ideal for custom-formed trays, inserts, and blister packs where product protection and visibility are key.

General Fabrication: Suitable for fabrication into various industrial parts, consumer products, and educational projects.

High Impact Strength: Offers superior durability and shock resistance compared to standard polystyrene, reducing the risk of cracking or breaking during handling or use.

Exceptional Ease of Fabrication: HIPS is renowned for its excellent thermoforming capabilities, especially in vacuum forming. It can be easily cut, routed, drilled, and bent using standard workshop tools without specialized equipment.

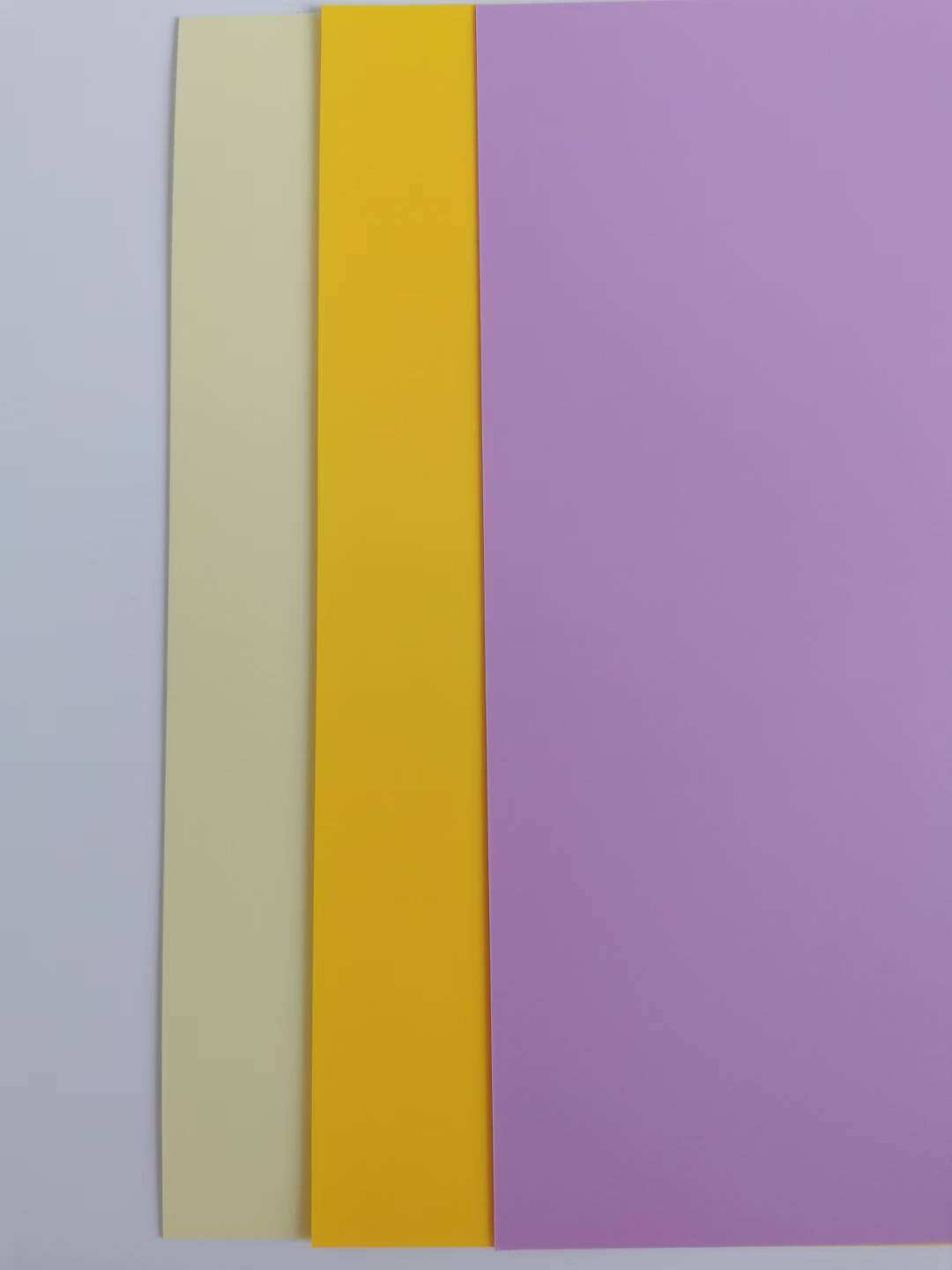

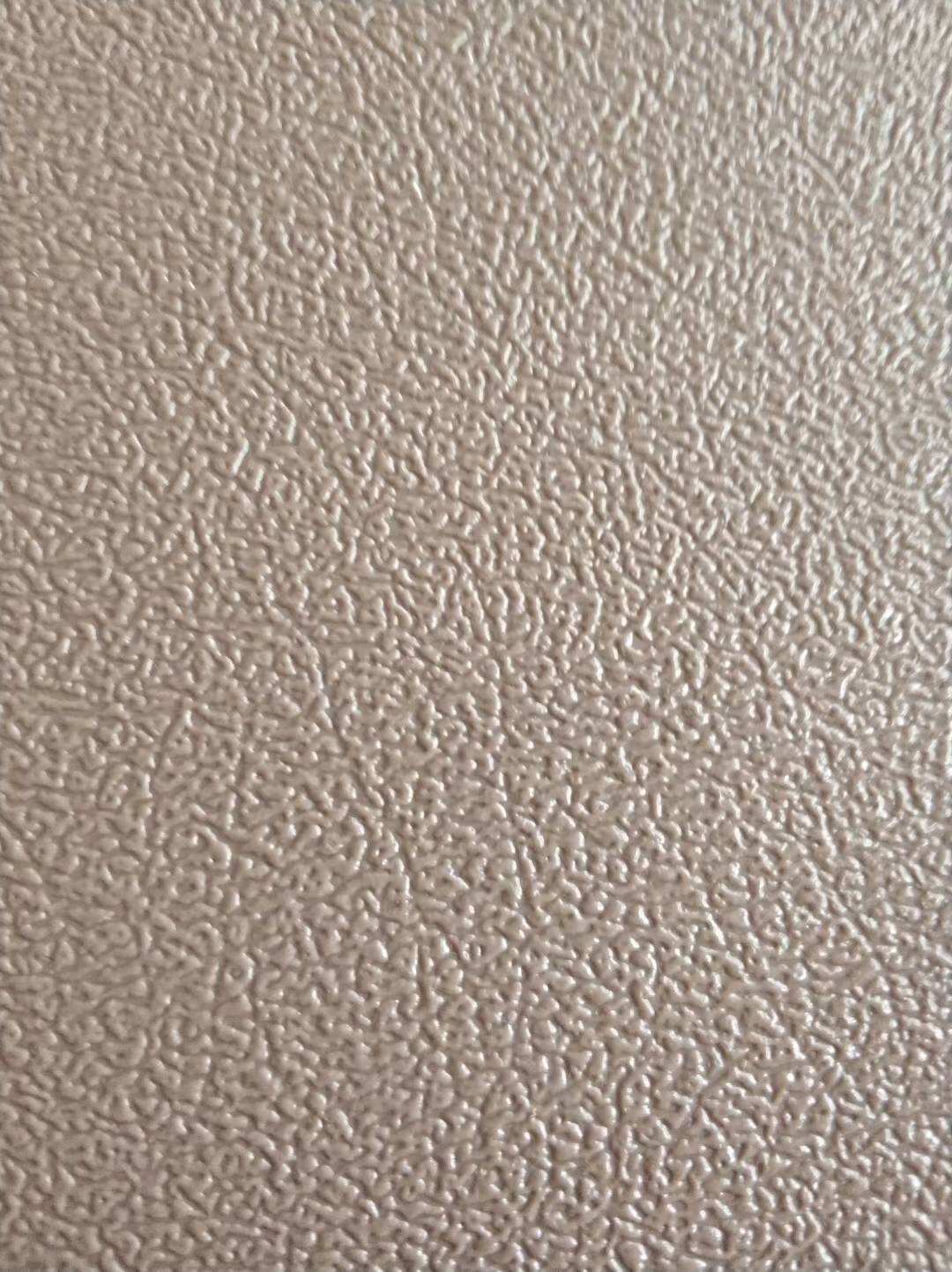

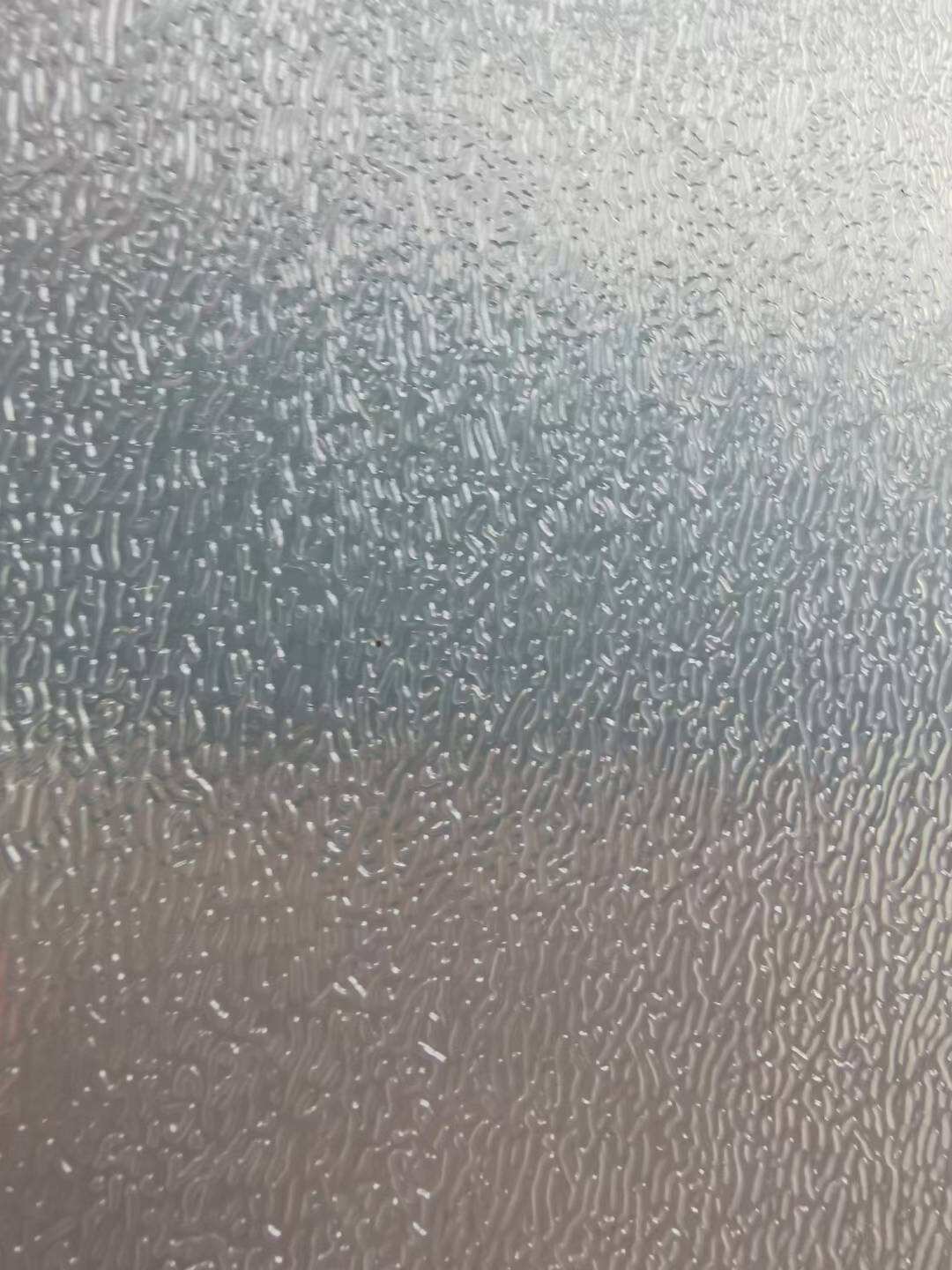

Superior Surface Finish: Provides a bright, white, and smooth surface that is ideal for direct printing, painting, gluing, and laminating. Achieve a professional, high-quality finish with minimal preparation.

Lightweight & Cost-Effective: As a low-density material, HIPS offers a high strength-to-weight ratio, reducing shipping costs and making it easy to handle. It provides outstanding value without compromising on performance.

Excellent 3D Printing Support: Widely used as a support material for ABS prints in FDM 3D printing. HIPS is soluble in limonene, allowing for clean and easy removal of supports from complex models.

1.What is the main difference between HIPS and ABS sheets?

Both HIPS and ABS are durable thermoplastics, but they have key differences. HIPS is primarily known for its ease of thermoforming and excellent performance as a soluble support material for 3D printing. ABS, on the other hand, generally offers higher heat resistance and superior mechanical strength. HIPS is often more cost-effective and is preferred for applications like vacuum forming and signage, while ABS is chosen for parts requiring higher durability and temperature resistance.

2. Can HIPS plastic be painted and glued easily?

Yes, absolutely. One of the key advantages of HIPS is its excellent surface finish, which makes it very easy to work with. It can be reliably bonded using most common plastic cements (cyanoacrylates/"Super Glue") and polystyrene cements. Its smooth, non-porous surface also accepts acrylic and enamel paints very well after a light sanding for optimal adhesion.

3. What is the best way to cut HIPS sheets?

HIPS is very easy to cut with standard tools. For straight cuts, a utility knife, plastic cutter, or table saw works excellently. For complex shapes, you can use a jigsaw, band saw, or laser cutter. When using power tools, use sharp blades and moderate speeds to prevent the plastic from melting from excessive friction.