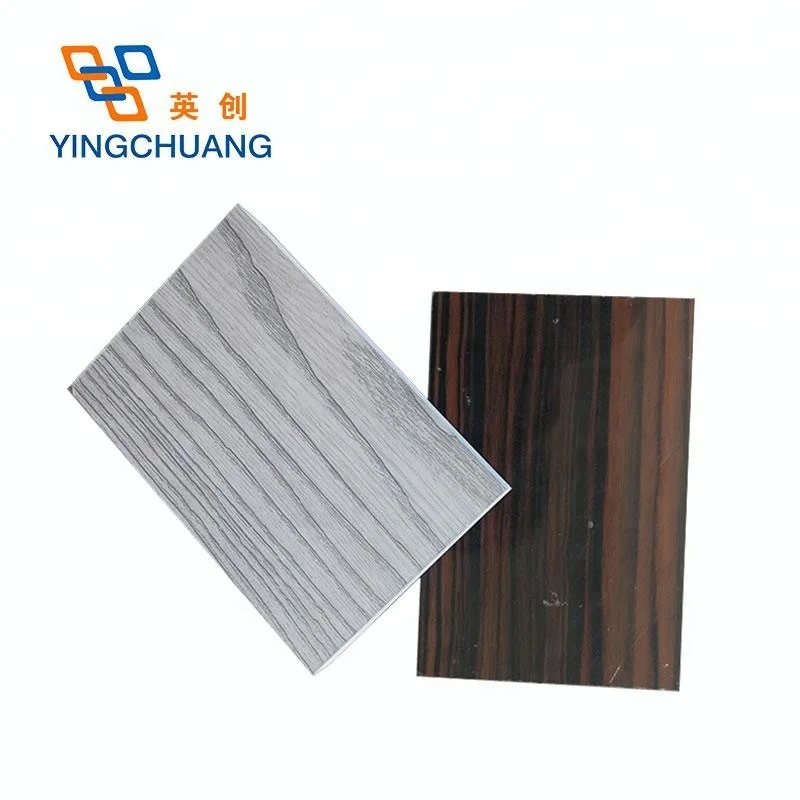

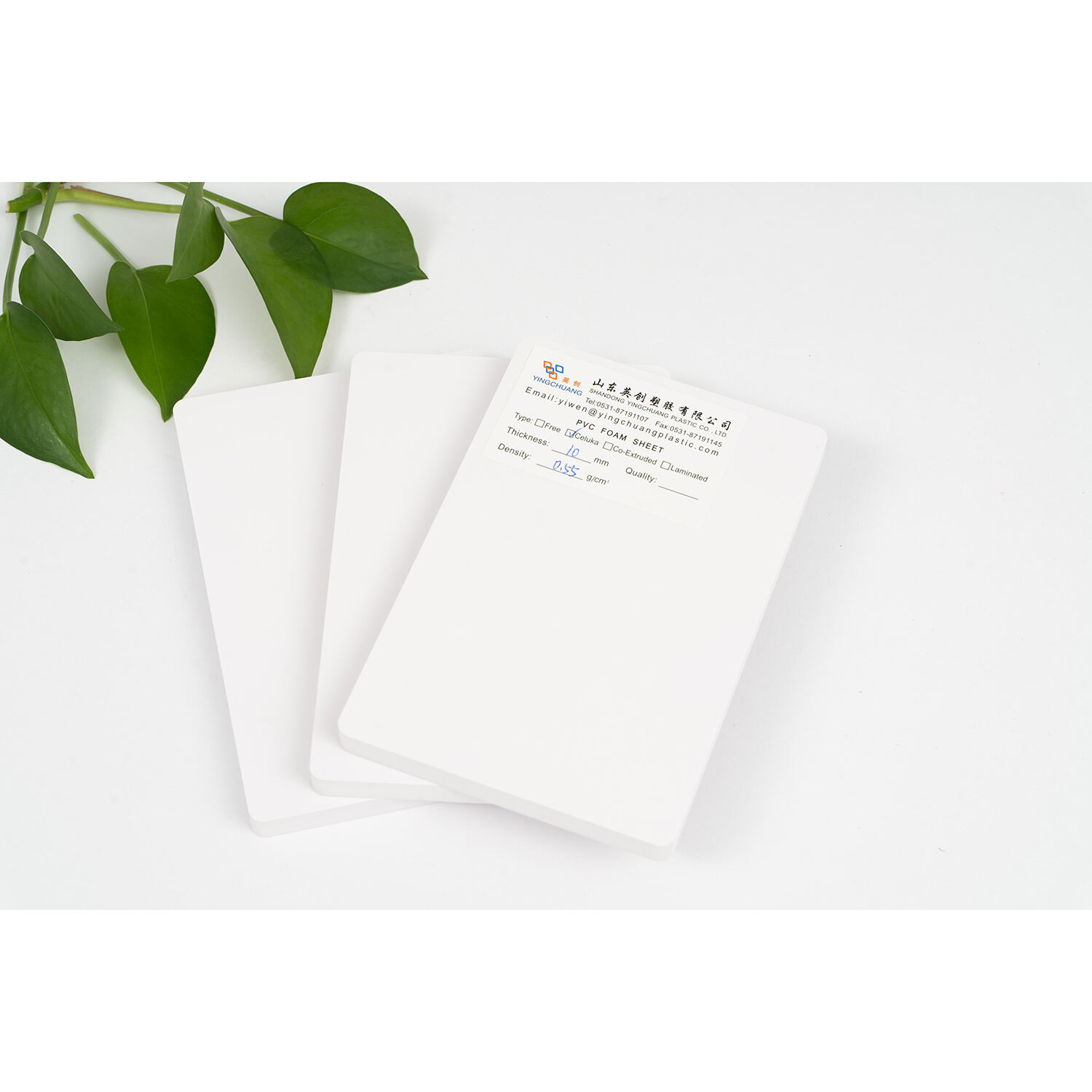

pvc foam panels

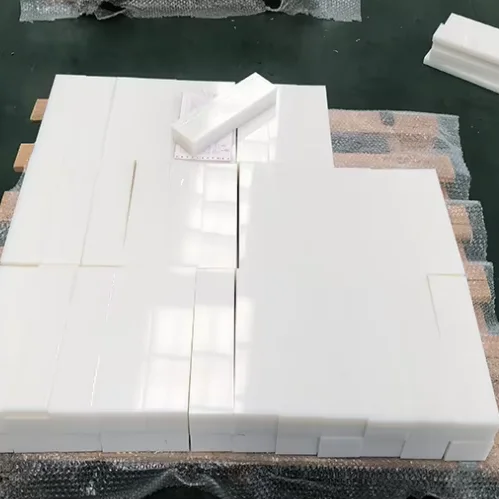

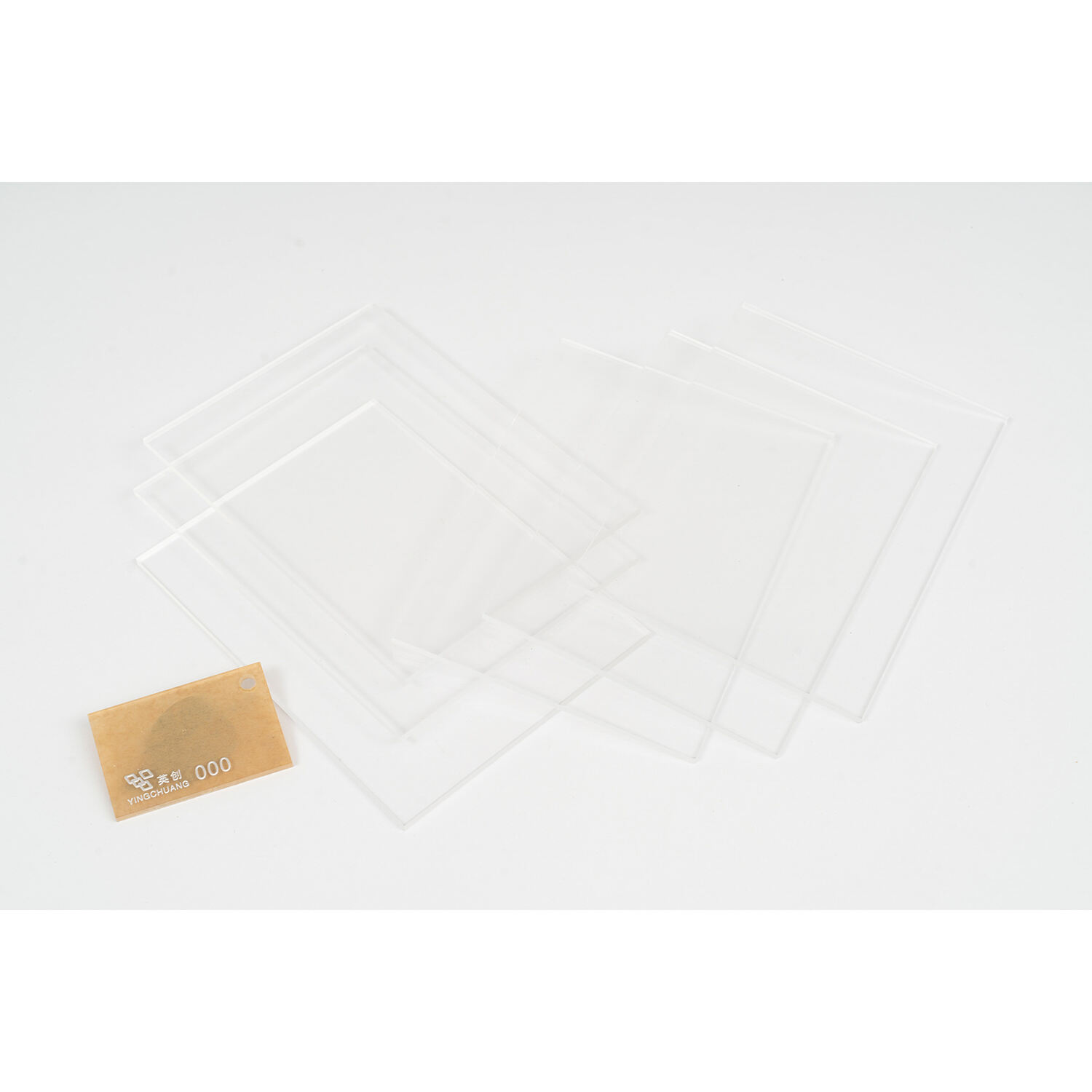

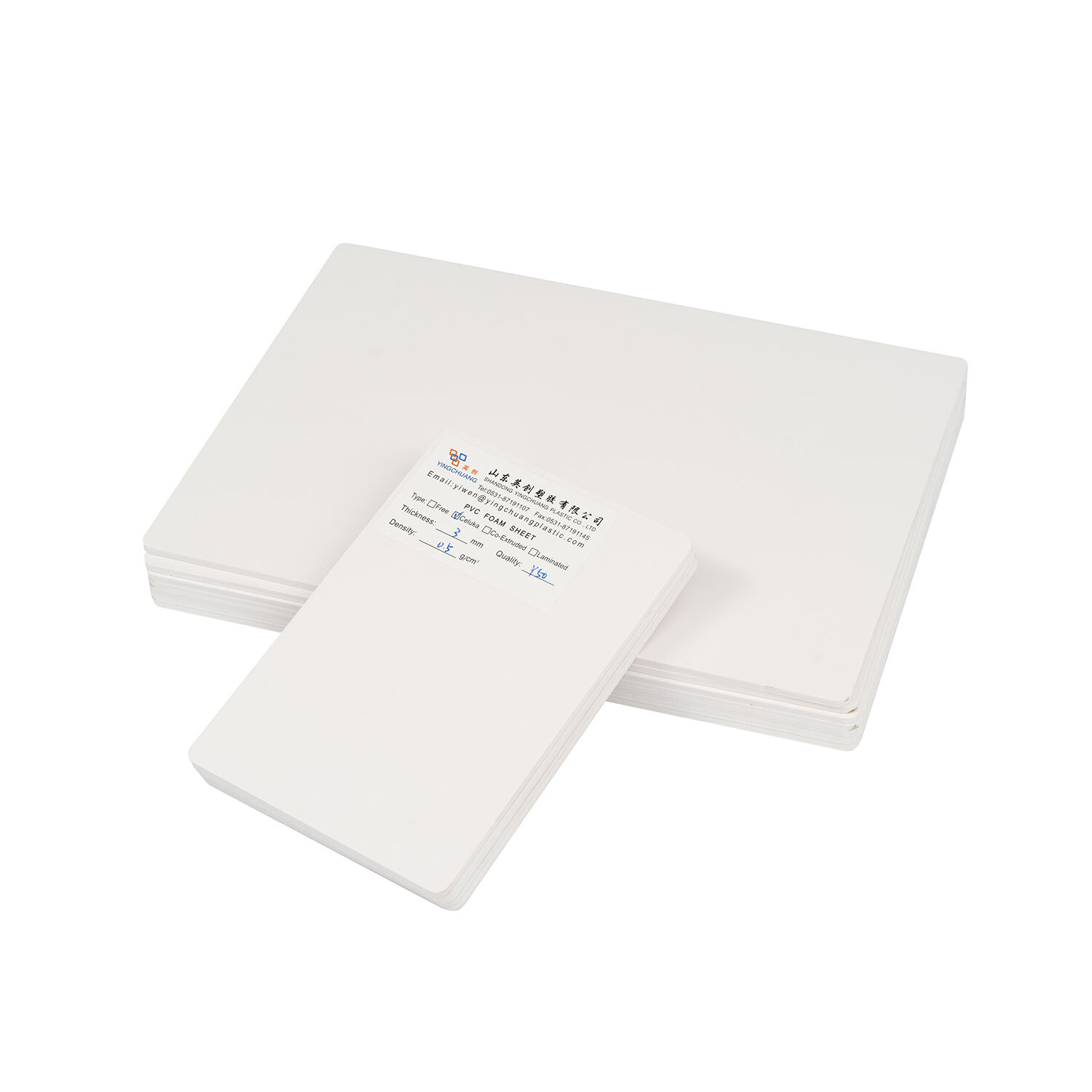

PVC foam panels represent a revolutionary building and construction material that combines durability, versatility, and cost-effectiveness. These panels are manufactured through an advanced process where polyvinyl chloride is mixed with chemical foaming agents, resulting in a lightweight yet sturdy material with exceptional thermal and acoustic properties. The cellular structure of PVC foam panels creates millions of tiny air pockets, providing superior insulation capabilities while maintaining structural integrity. These panels feature a smooth, uniform surface that's ideal for various finishing applications, including painting, laminating, and direct printing. Their closed-cell composition ensures moisture resistance and prevents water absorption, making them particularly suitable for humid environments and outdoor applications. The panels come in various thicknesses and densities, allowing for customization according to specific project requirements. They excel in both interior and exterior applications, from wall cladding and ceiling systems to signage and marine applications. The material's fire-retardant properties and resistance to chemical agents further enhance its safety profile and longevity. With their exceptional workability, these panels can be cut, drilled, and shaped using standard woodworking tools, making them highly adaptable for diverse construction and fabrication needs.