pvc foam core sheet

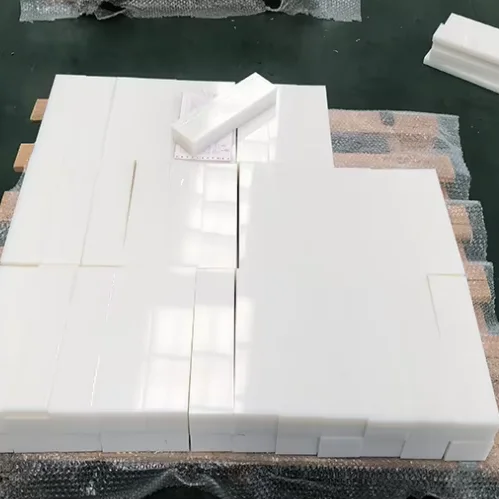

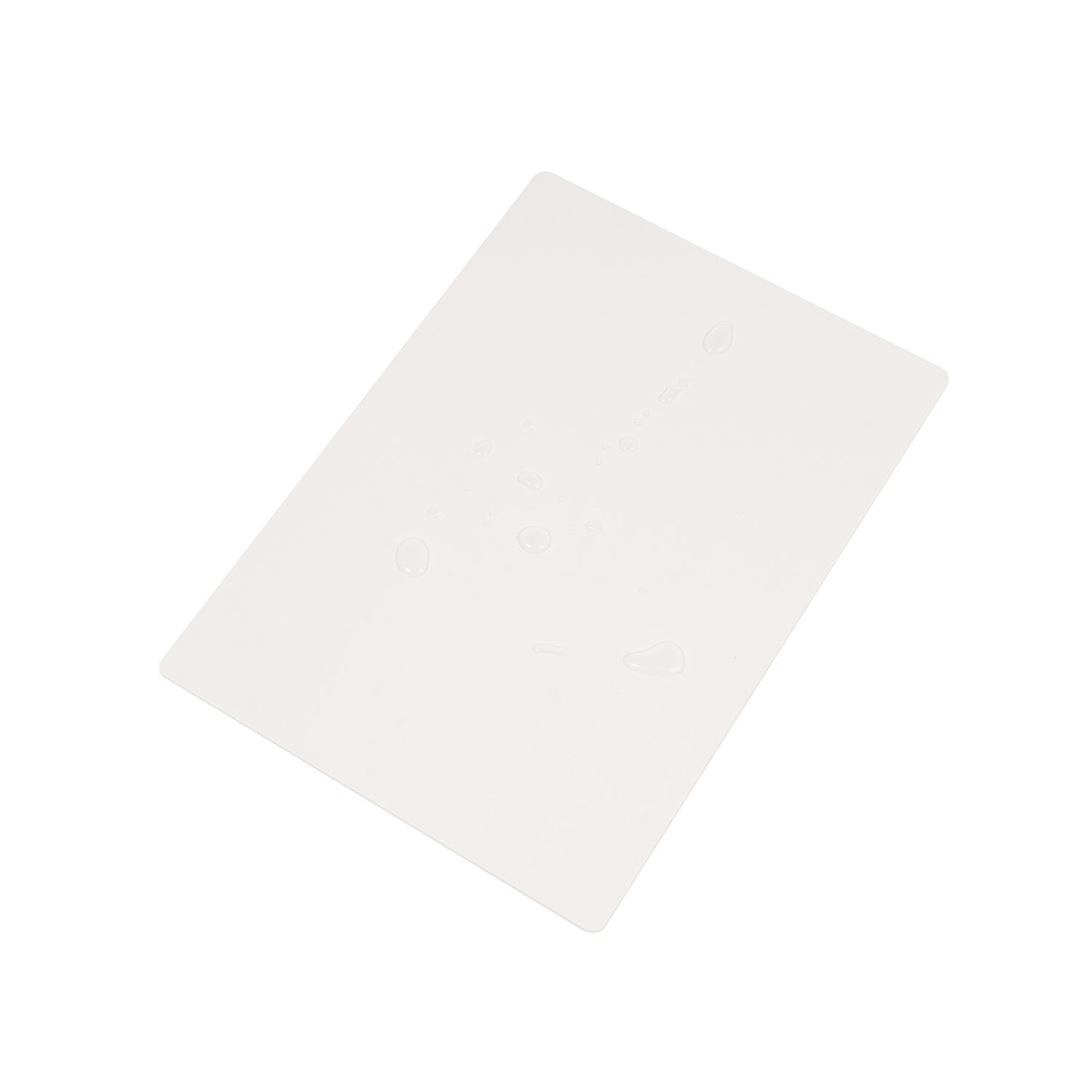

PVC foam core sheet is an advanced composite material that combines lightweight properties with exceptional strength and durability. This versatile material consists of a closed-cell PVC foam structure that provides outstanding thermal insulation, moisture resistance, and sound dampening capabilities. The sheets are manufactured through a sophisticated process that creates uniform cell structures, ensuring consistent performance across the entire surface. With densities ranging from 40 to 80 kg/m3, these sheets offer excellent strength-to-weight ratios, making them ideal for various applications in marine, construction, and industrial sectors. The material's closed-cell structure prevents water absorption while maintaining structural integrity, even in challenging environmental conditions. PVC foam core sheets exhibit remarkable compression strength and shear properties, making them suitable for sandwich panel constructions where high performance and reliability are essential. Their excellent chemical resistance and UV stability ensure long-term durability, while the smooth surface finish facilitates easy lamination and bonding with various facing materials. The sheets can be easily fabricated using standard woodworking tools, allowing for cost-effective processing and installation. Their fire-retardant properties and low thermal conductivity make them particularly valuable in applications requiring safety compliance and energy efficiency.