pvc foam board sheet price

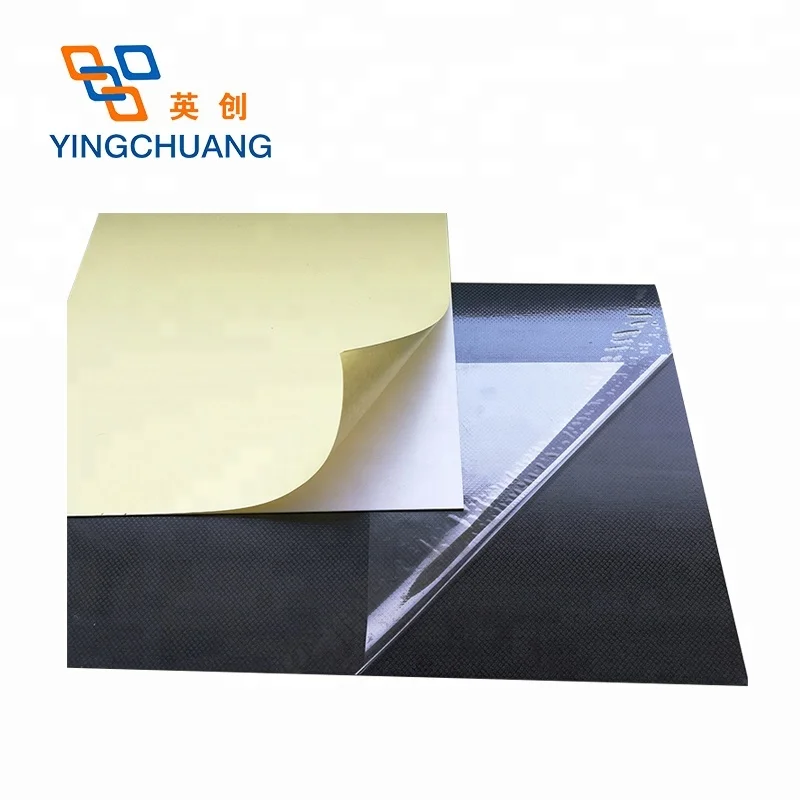

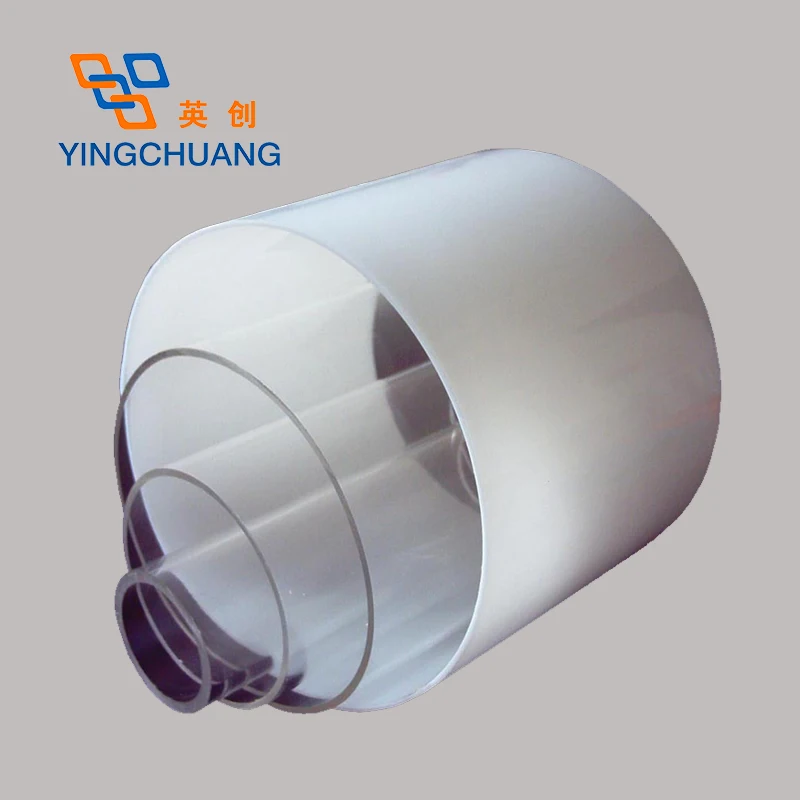

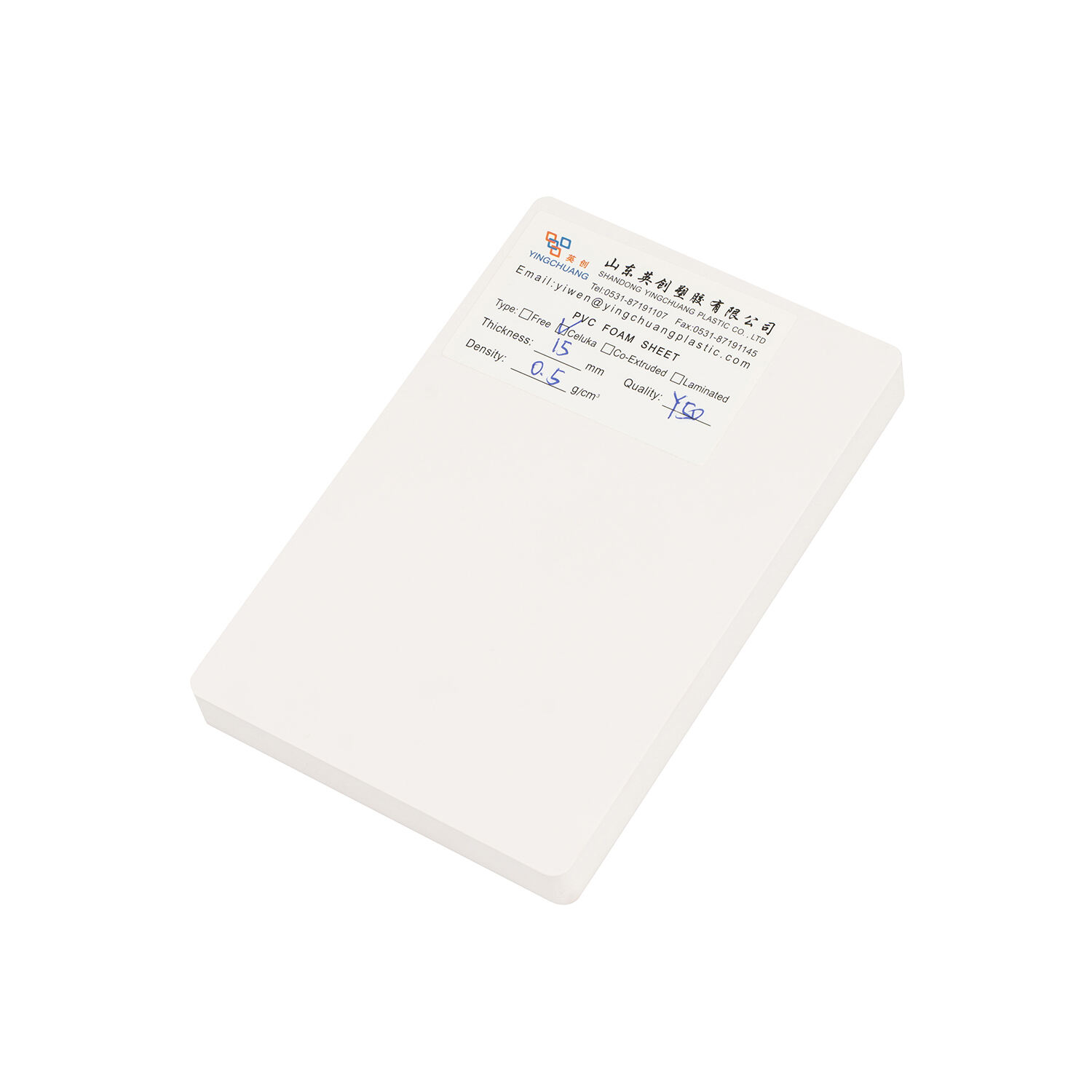

PVC foam board sheet pricing represents a crucial consideration in the construction and signage industries, offering a cost-effective solution for various applications. These versatile sheets are manufactured through an advanced extrusion process that creates a lightweight yet durable material with a cellular structure. The price typically ranges from $2 to $15 per square foot, depending on thickness, density, and quantity ordered. The sheets are available in various dimensions, commonly from 4x8 feet to 6x10 feet, with thicknesses ranging from 1mm to 30mm. The pricing structure reflects the material's superior characteristics, including excellent weather resistance, fire retardancy, and insulation properties. Manufacturers often offer bulk purchase discounts, making it more economical for large-scale projects. The cost also varies based on additional features such as UV protection, specific color requirements, and surface finish options. When considering PVC foam board sheet prices, it's essential to factor in the material's long-term durability and low maintenance requirements, which contribute to its overall cost-effectiveness.