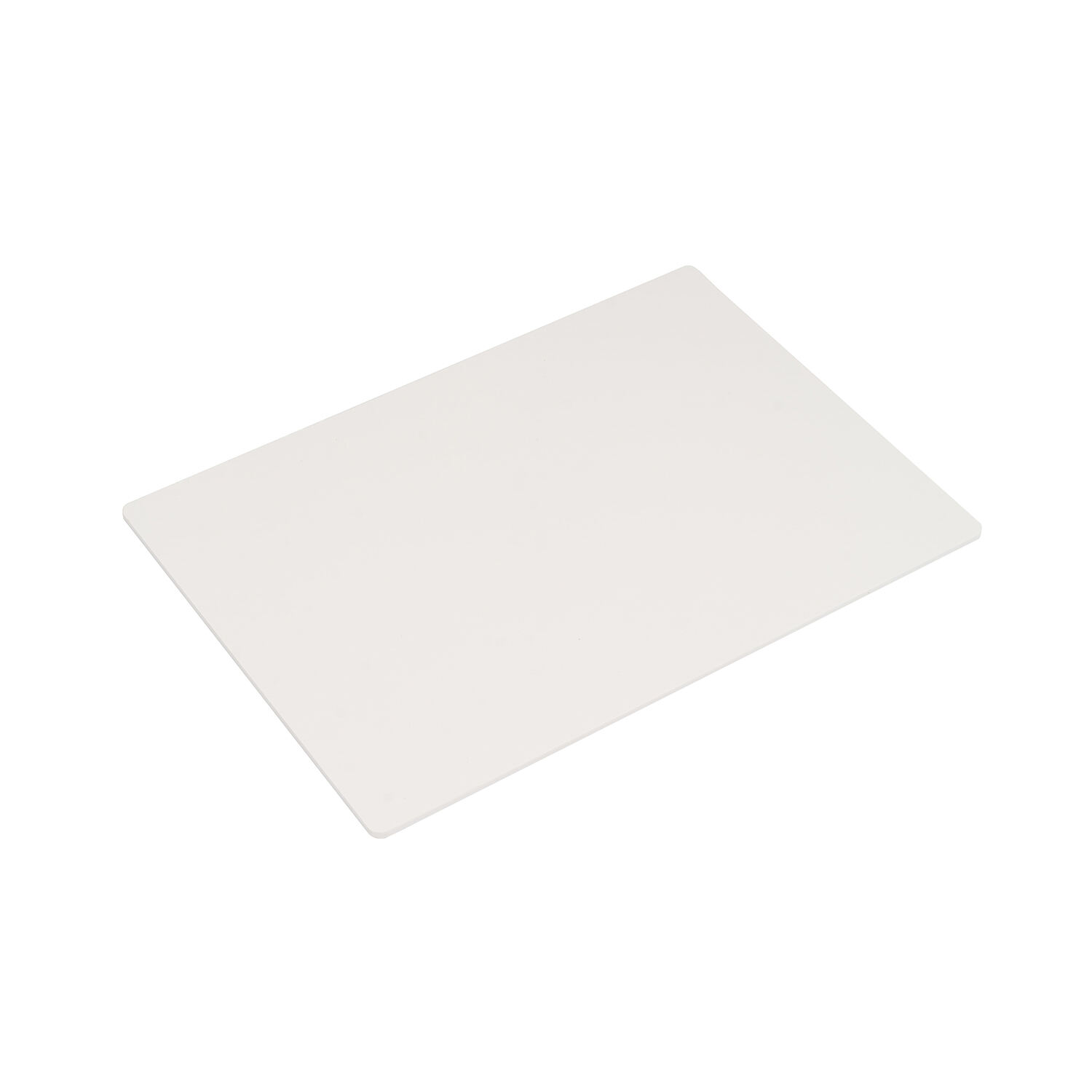

pvc celuka foam sheet

PVC Celuka foam sheet represents a revolutionary advancement in construction and industrial materials, offering a unique combination of durability and versatility. This innovative material is manufactured through a specialized extrusion process that creates a dense outer skin and a lightweight foamed core, resulting in a sheet with exceptional structural integrity. The manufacturing process involves heating PVC compounds with foaming agents, creating a uniform cellular structure throughout the material while maintaining a smooth, solid surface layer. These sheets typically range in thickness from 1mm to 30mm and can be produced in various densities to suit different applications. The material's closed-cell structure provides excellent resistance to moisture, chemicals, and environmental factors, making it ideal for both indoor and outdoor applications. Its low maintenance requirements and long service life make it a cost-effective solution for various construction and industrial needs. The sheets can be easily fabricated using standard woodworking tools, allowing for cutting, drilling, and shaping without specialized equipment. Additionally, the material's inherent fire-retardant properties and compliance with international safety standards make it suitable for applications where safety is paramount.