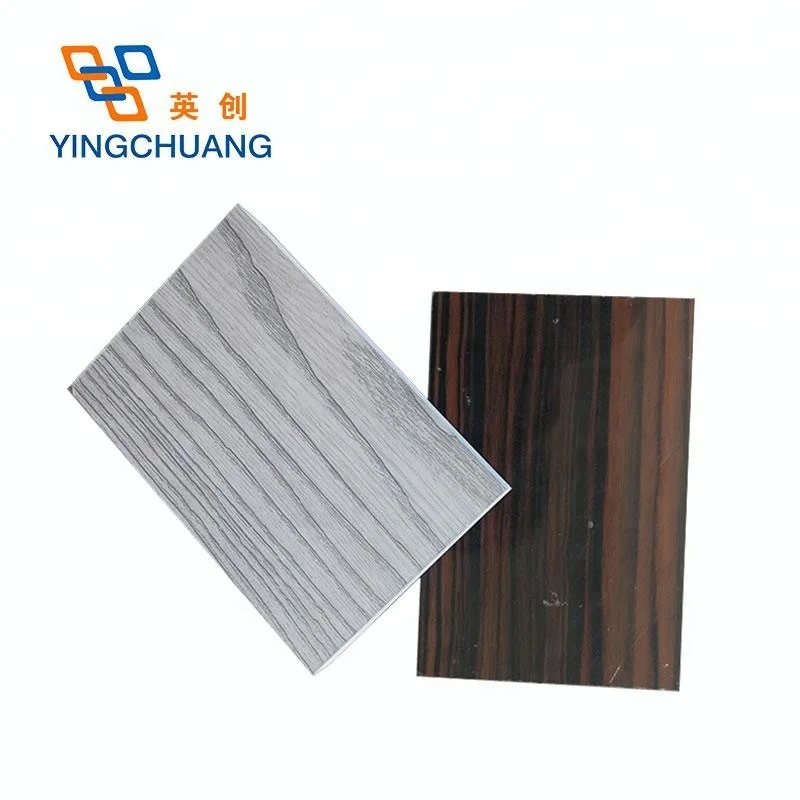

pvc foam board manufacturer

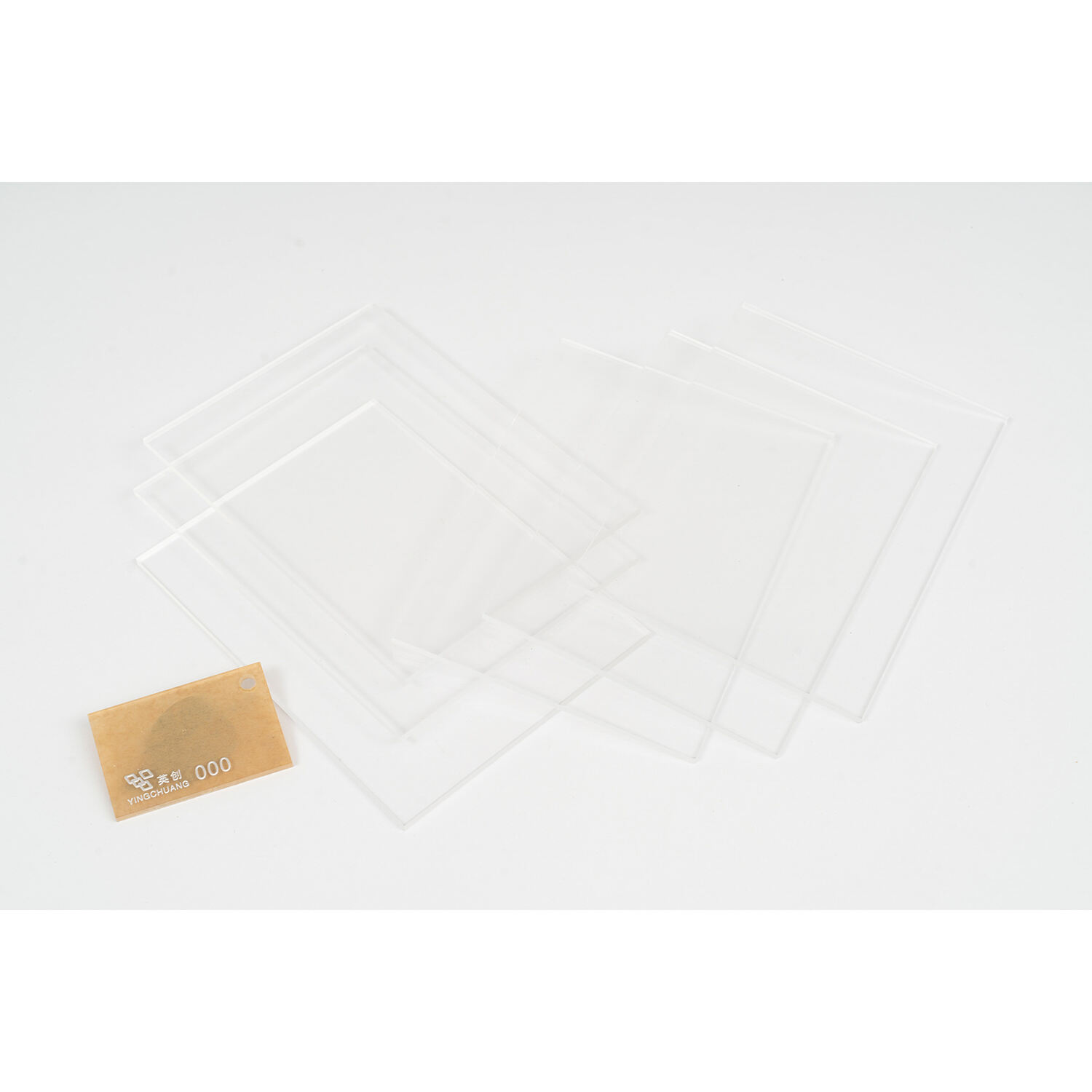

A PVC foam board manufacturer specializes in producing versatile, lightweight construction materials that have revolutionized modern building and design applications. These manufacturers employ advanced extrusion technology to create cellular PVC sheets with a consistent, closed-cell structure that offers exceptional durability and versatility. The manufacturing process involves mixing PVC resin with specific chemical foaming agents, stabilizers, and modifiers, which are then processed through sophisticated temperature-controlled systems. This results in boards with varying densities and thicknesses, customizable to meet diverse industry requirements. The facilities typically feature state-of-the-art quality control systems that monitor density, cell structure, and surface finish throughout the production process. Modern manufacturers utilize automated cutting and finishing equipment to ensure precise dimensioning and smooth edges. These facilities often maintain extensive research and development departments focused on improving product performance, developing new formulations, and exploring innovative applications. The manufacturing process is environmentally conscious, often incorporating recycled materials and implementing waste reduction strategies.