pvc foam board

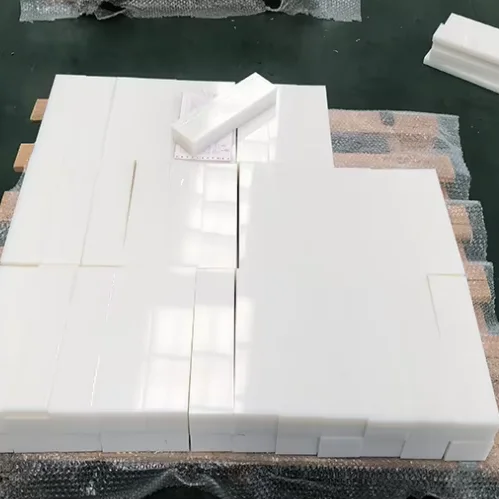

PVC foam board is a versatile construction and signage material that combines lightweight properties with exceptional durability. This innovative material consists of a cellular polyvinyl chloride core that creates a rigid yet lightweight structure. The board features a smooth, uniform surface on both sides, making it ideal for printing and various applications. Its closed-cell structure provides excellent water resistance and insulation properties, while the UV-stabilized composition ensures long-term performance in outdoor environments. The material's density typically ranges from 0.45 to 0.65 g/cm³, offering an optimal balance between weight and structural integrity. PVC foam board is manufactured through an advanced extrusion process that creates a consistent cell structure throughout the material, ensuring uniform properties and performance. The board comes in various thicknesses, typically from 1mm to 30mm, and can be easily customized to meet specific project requirements. Its chemical resistance makes it suitable for diverse environments, while its fire-retardant properties enhance safety in various applications. The material's workability allows for easy cutting, drilling, and mounting, making it a preferred choice for both construction professionals and creative designers.