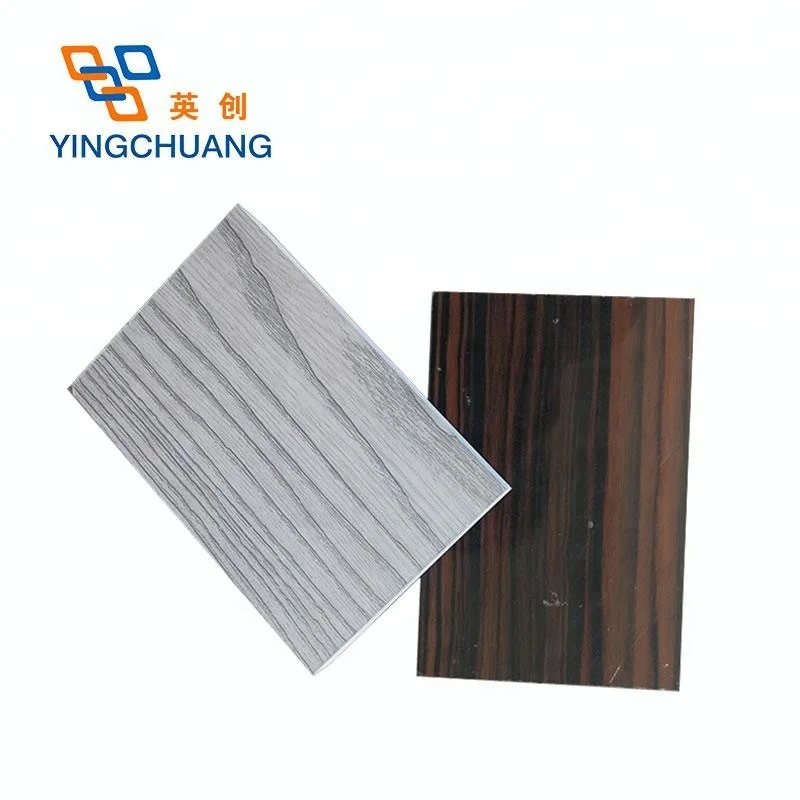

pvc foam

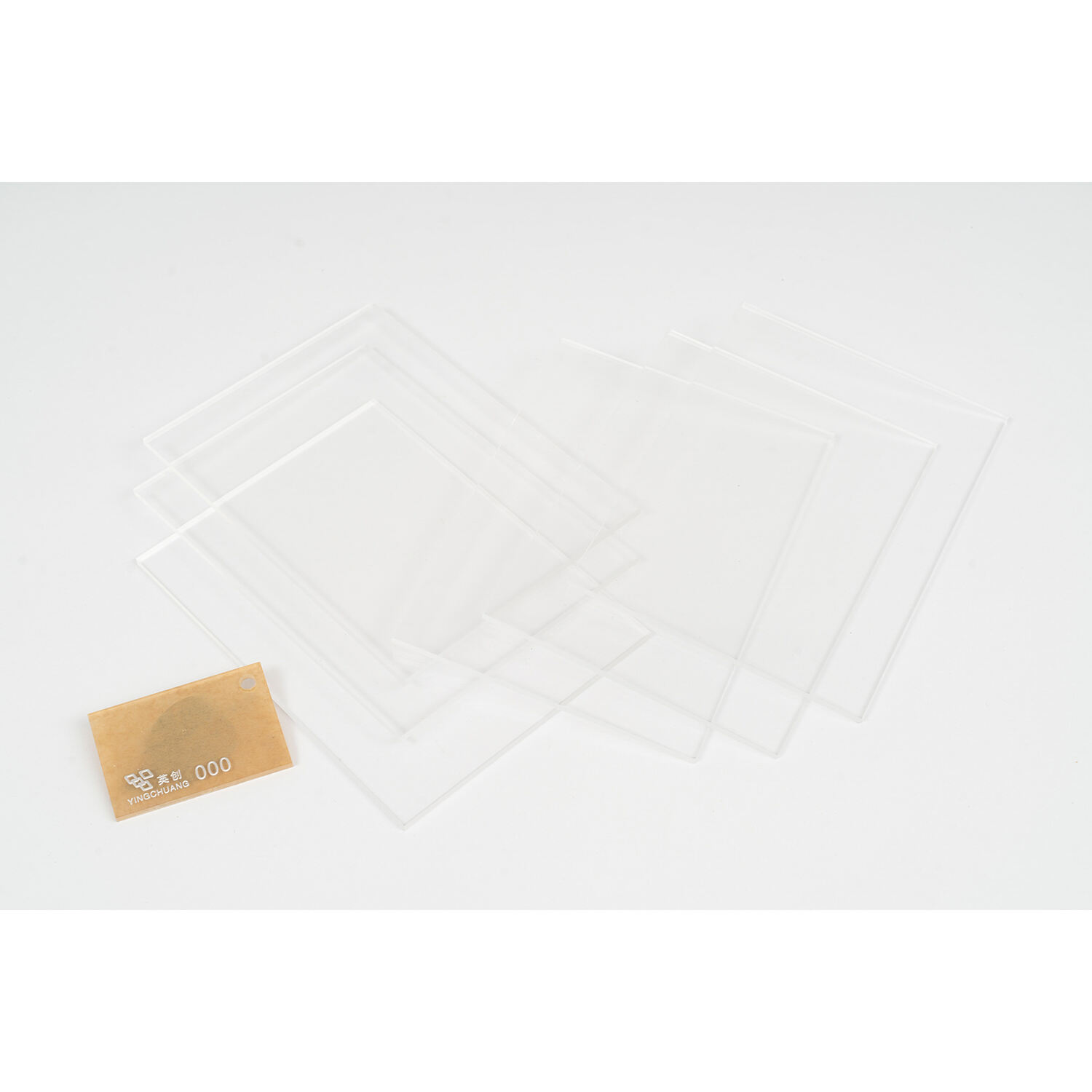

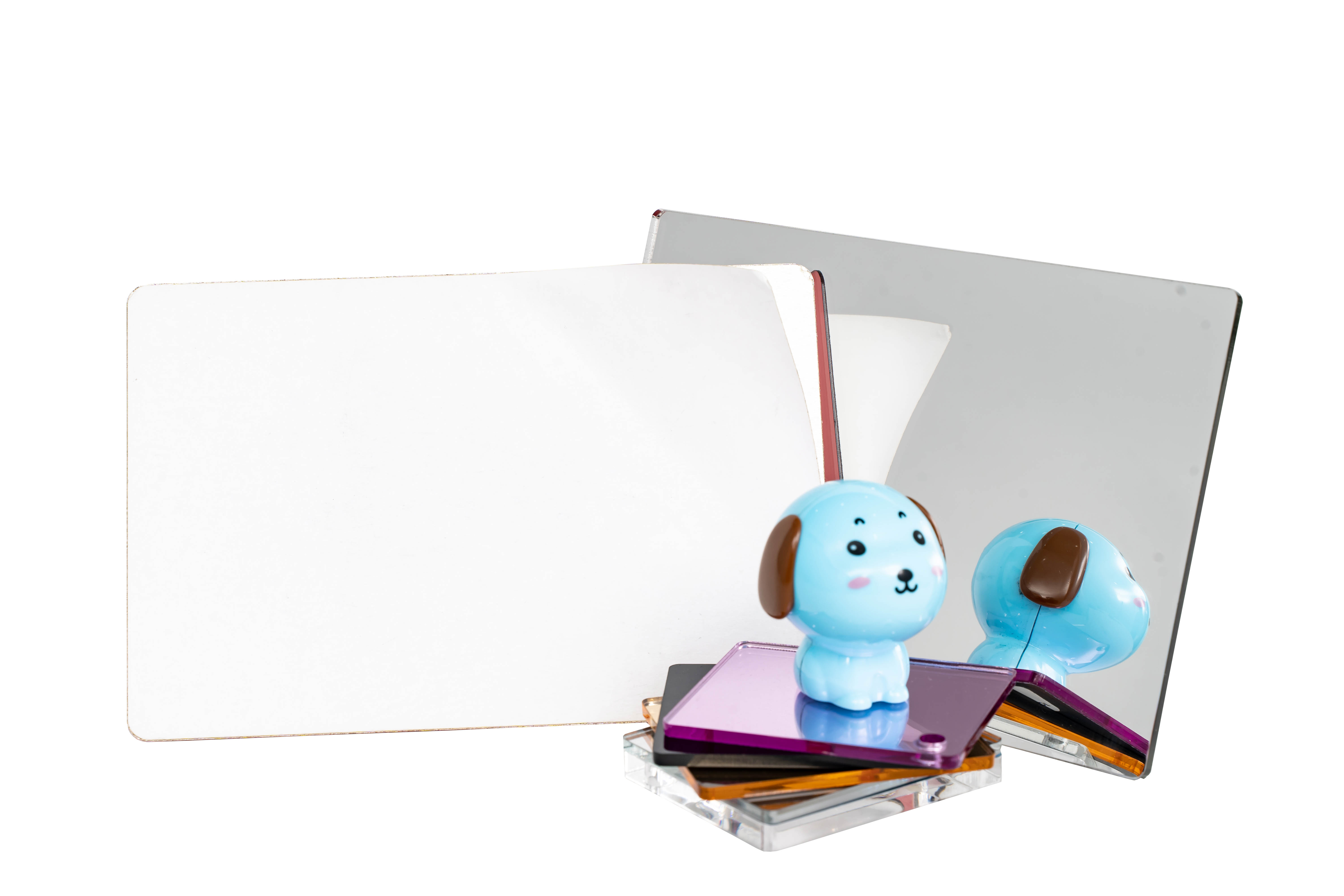

PVC foam represents a versatile and innovative material that combines the durability of PVC with the lightweight properties of cellular structures. This advanced material consists of polyvinyl chloride that has been processed to create a closed-cell structure, resulting in a lightweight yet robust material. The manufacturing process involves the careful introduction of gas bubbles into the PVC matrix, creating a uniform cellular structure that provides exceptional insulation properties and structural integrity. PVC foam sheets and boards are engineered to deliver outstanding performance across various applications, featuring excellent chemical resistance, weather resistance, and thermal insulation capabilities. The material's closed-cell structure prevents water absorption, making it ideal for marine and outdoor applications. With densities ranging from low to high, PVC foam can be customized to meet specific requirements in terms of strength, weight, and performance characteristics. The material's exceptional workability allows for easy cutting, shaping, and fabrication, making it suitable for both industrial applications and creative projects. Modern PVC foam products also incorporate UV stabilizers and fire-retardant additives, enhancing their durability and safety properties for long-term use in demanding environments.