custom size acrylic sheet

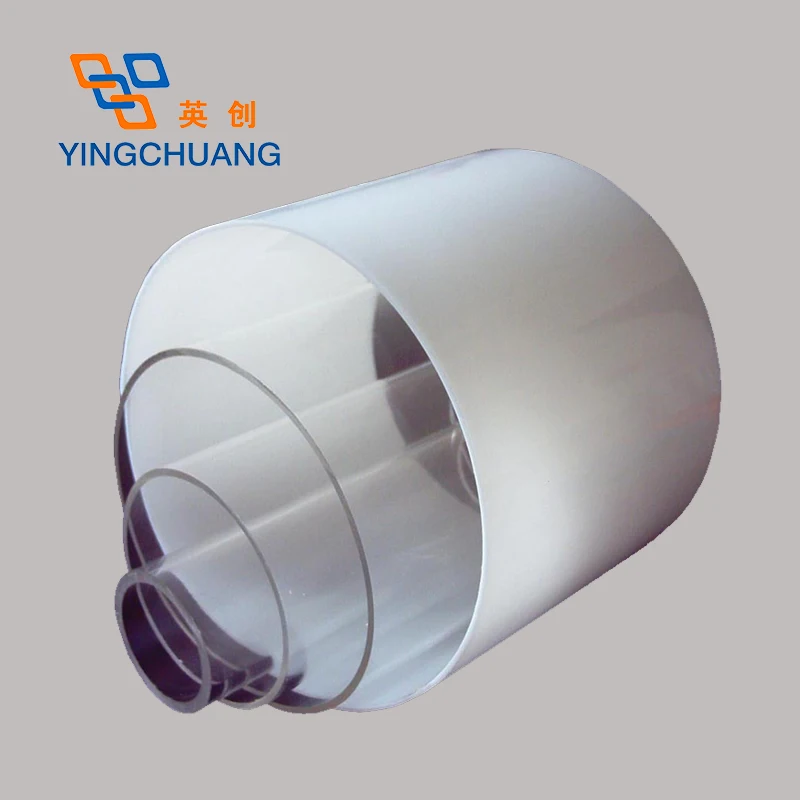

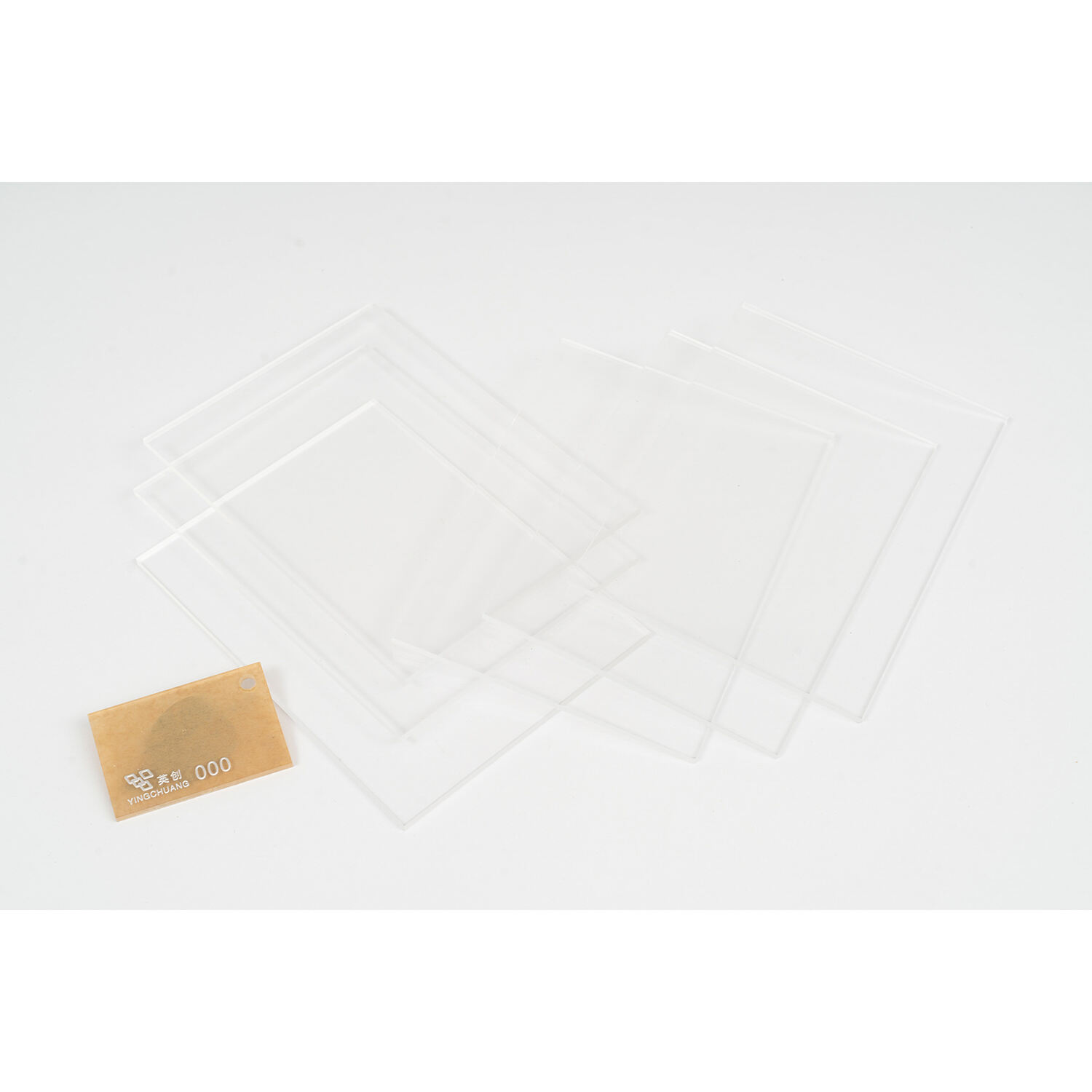

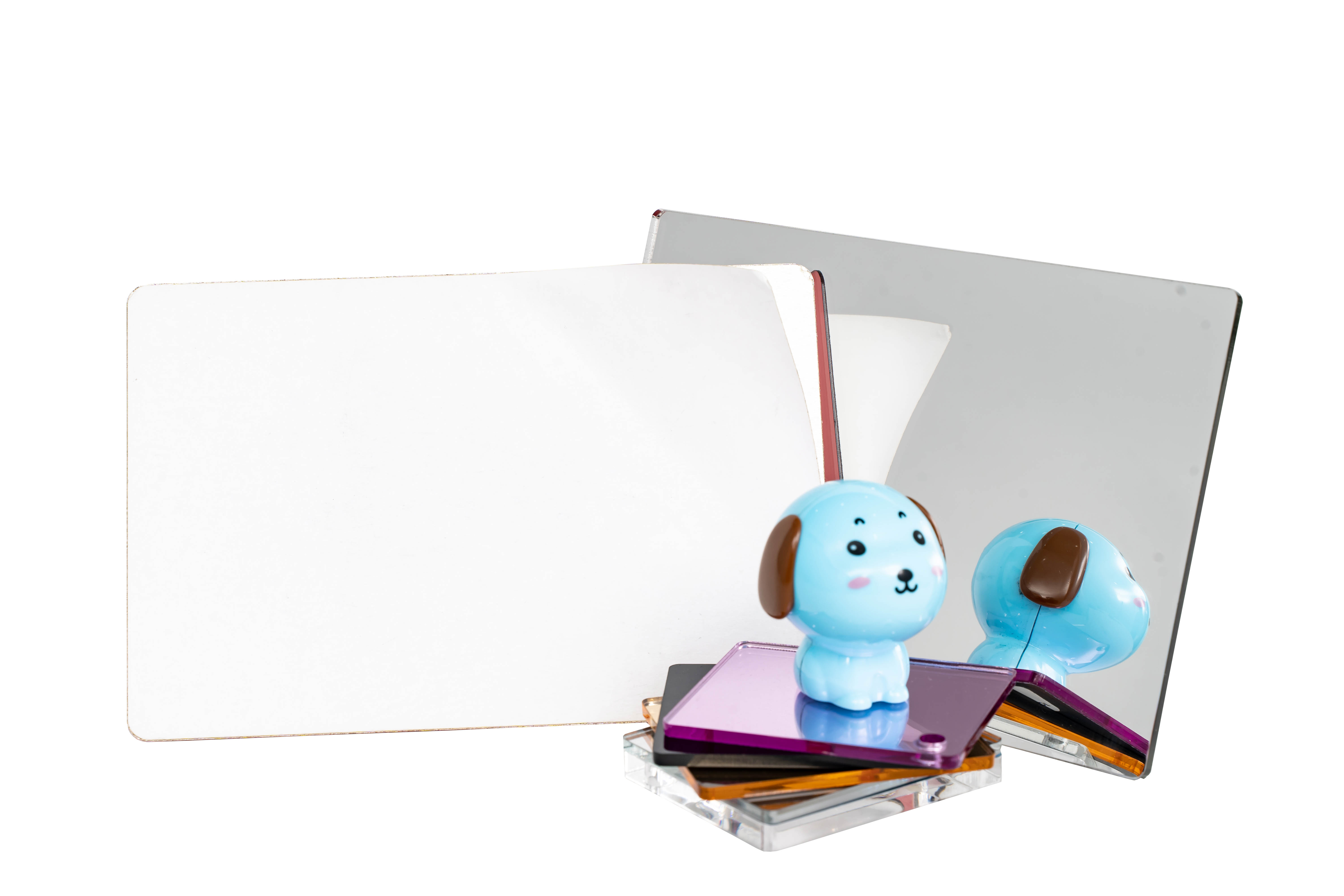

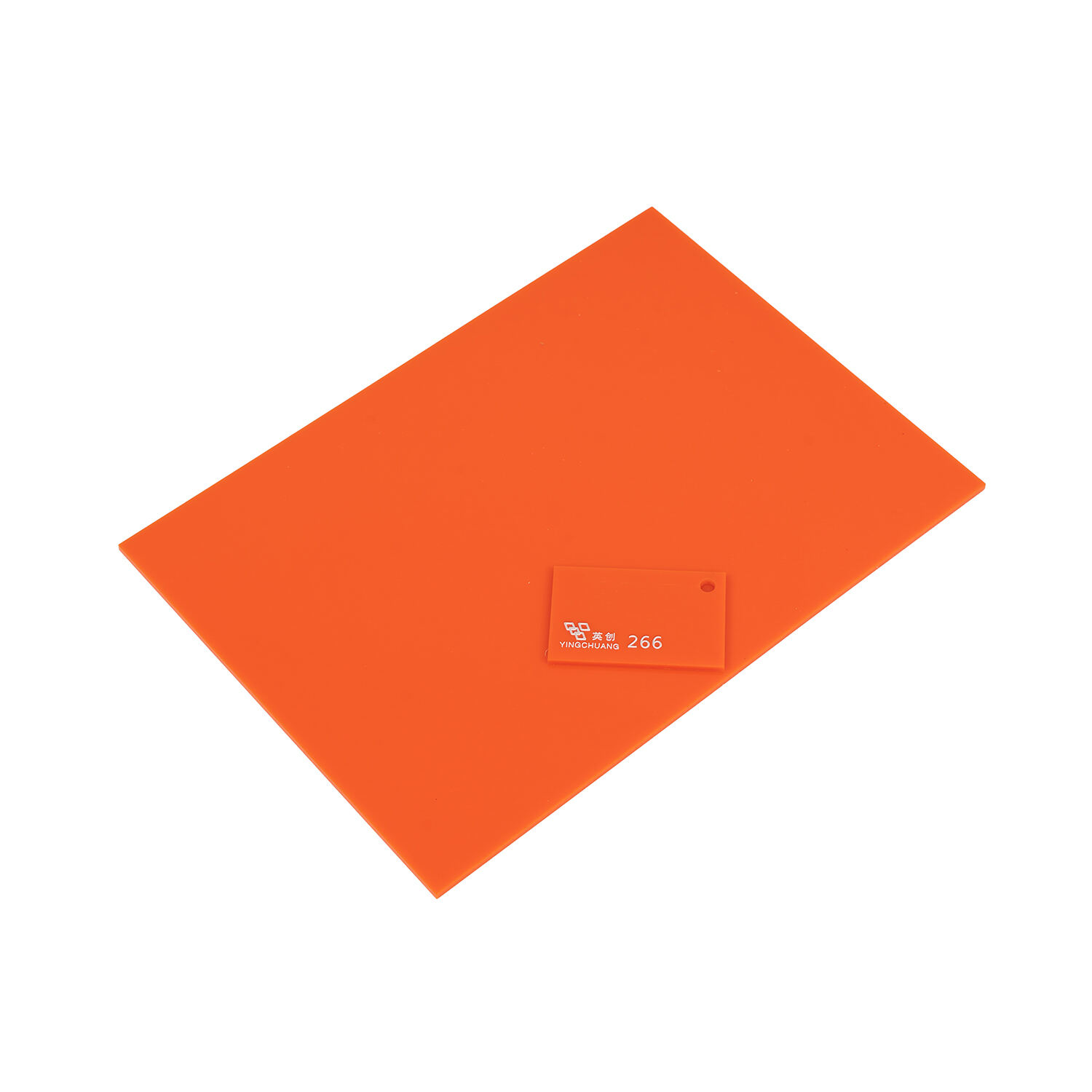

Custom size acrylic sheets represent a versatile and adaptable solution for various applications, offering remarkable clarity and durability comparable to glass but with added benefits. These sheets are manufactured through a precise process that allows for specific dimensions and thicknesses according to customer requirements. The material consists of polymethyl methacrylate (PMMA), providing exceptional light transmission properties of up to 92% and UV resistance. Custom acrylic sheets can be fabricated in thicknesses ranging from 1mm to 50mm, with the ability to accommodate unique size specifications for particular projects. The sheets demonstrate remarkable impact resistance, being 17 times stronger than traditional glass while maintaining only half the weight. They excel in both indoor and outdoor applications, maintaining their structural integrity and optical clarity across varying environmental conditions. The customization process involves advanced cutting technologies, including laser and CNC machining, ensuring precise dimensions and clean edges. These sheets can be further modified through various fabrication methods such as heating, bending, and polishing, making them suitable for architectural installations, retail displays, signage, protective barriers, and artistic installations. The material's inherent properties make it resistant to many chemicals and weathering effects, ensuring long-term durability and maintaining aesthetic appeal throughout its service life.