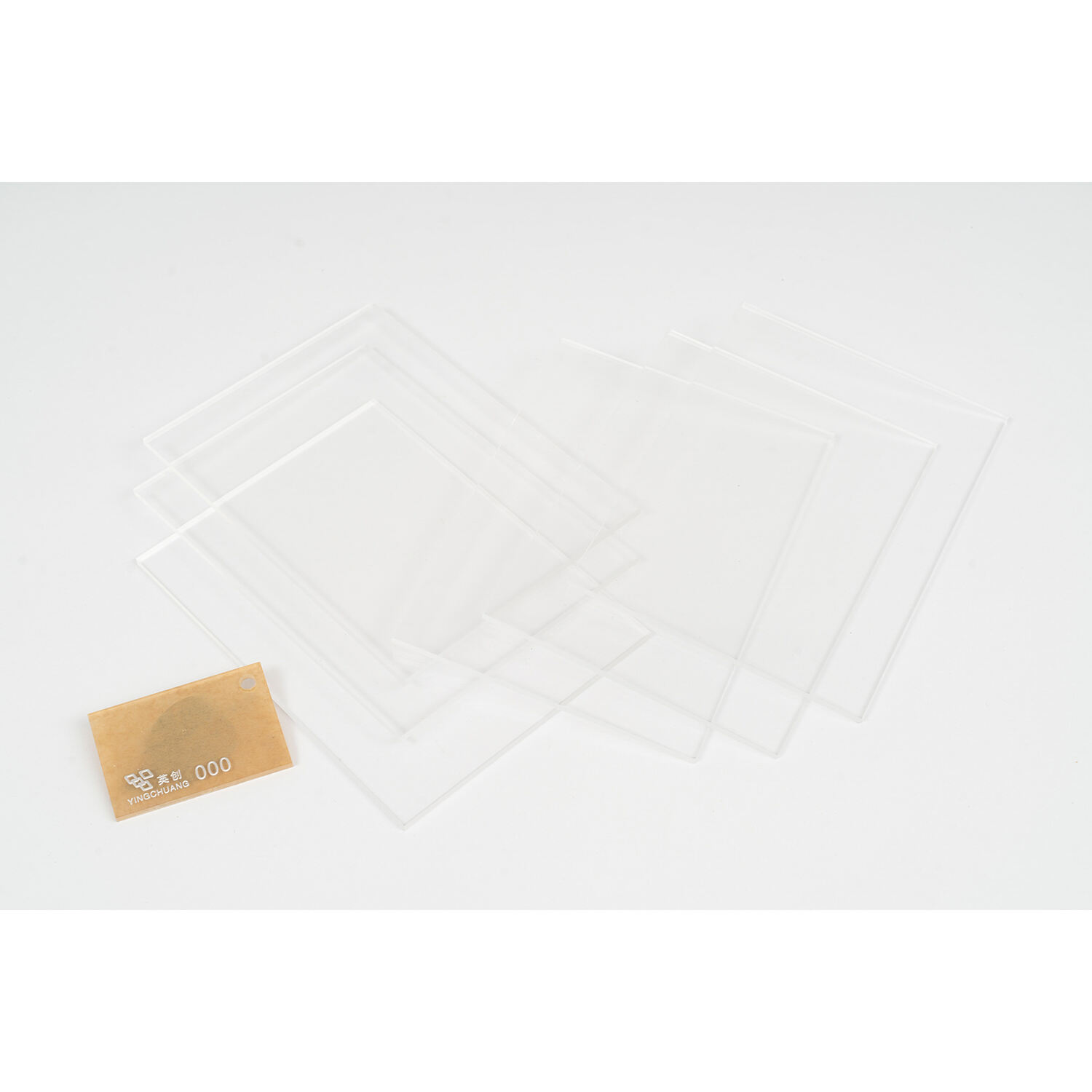

custom cut plexiglass sheets

Custom cut plexiglass sheets represent a versatile and durable acrylic material solution that offers exceptional clarity and customization possibilities. These sheets are precision-engineered using advanced cutting technology to meet specific dimensional requirements, making them ideal for various applications across multiple industries. The material boasts superior impact resistance compared to traditional glass while maintaining crystal-clear transparency and lightweight properties. Custom cut plexiglass sheets can be manufactured in various thicknesses, ranging from thin displays to robust structural applications, and can be modified with different finishes, including matte, glossy, or textured surfaces. The cutting process ensures exact measurements and clean edges, eliminating the need for post-processing in most cases. These sheets also offer excellent weather resistance, UV protection, and thermal insulation properties, making them suitable for both indoor and outdoor applications. The versatility of custom cut plexiglass extends to its ability to be thermoformed, bent, and modified to create complex shapes while maintaining structural integrity and optical clarity.