The world of decorative materials has been revolutionized by the introduction of glitter acrylic sheet options that combine functionality with stunning visual appeal. These versatile materials offer architects, designers, and crafters an innovative way to incorporate sparkle and glamour into their projects without compromising durability or structural integrity. Understanding the vast array of colors and styles available in glitter acrylic sheet products enables professionals to make informed decisions that align with their creative vision and practical requirements.

Understanding Glitter Acrylic Sheet Composition

Material Structure and Manufacturing Process

The manufacturing process of glitter acrylic sheet involves embedding reflective particles within a clear or colored acrylic substrate during the casting process. This technique ensures that the glitter elements become permanently integrated into the material structure, preventing particle separation or loss over time. The base acrylic polymer provides excellent optical clarity while maintaining the mechanical properties necessary for various applications.

Advanced production methods utilize specialized casting techniques that distribute glitter particles uniformly throughout the sheet thickness. This distribution pattern creates consistent sparkle effects across the entire surface area while maintaining structural stability. The controlled environment during manufacturing ensures that each glitter acrylic sheet meets strict quality standards for optical performance and physical durability.

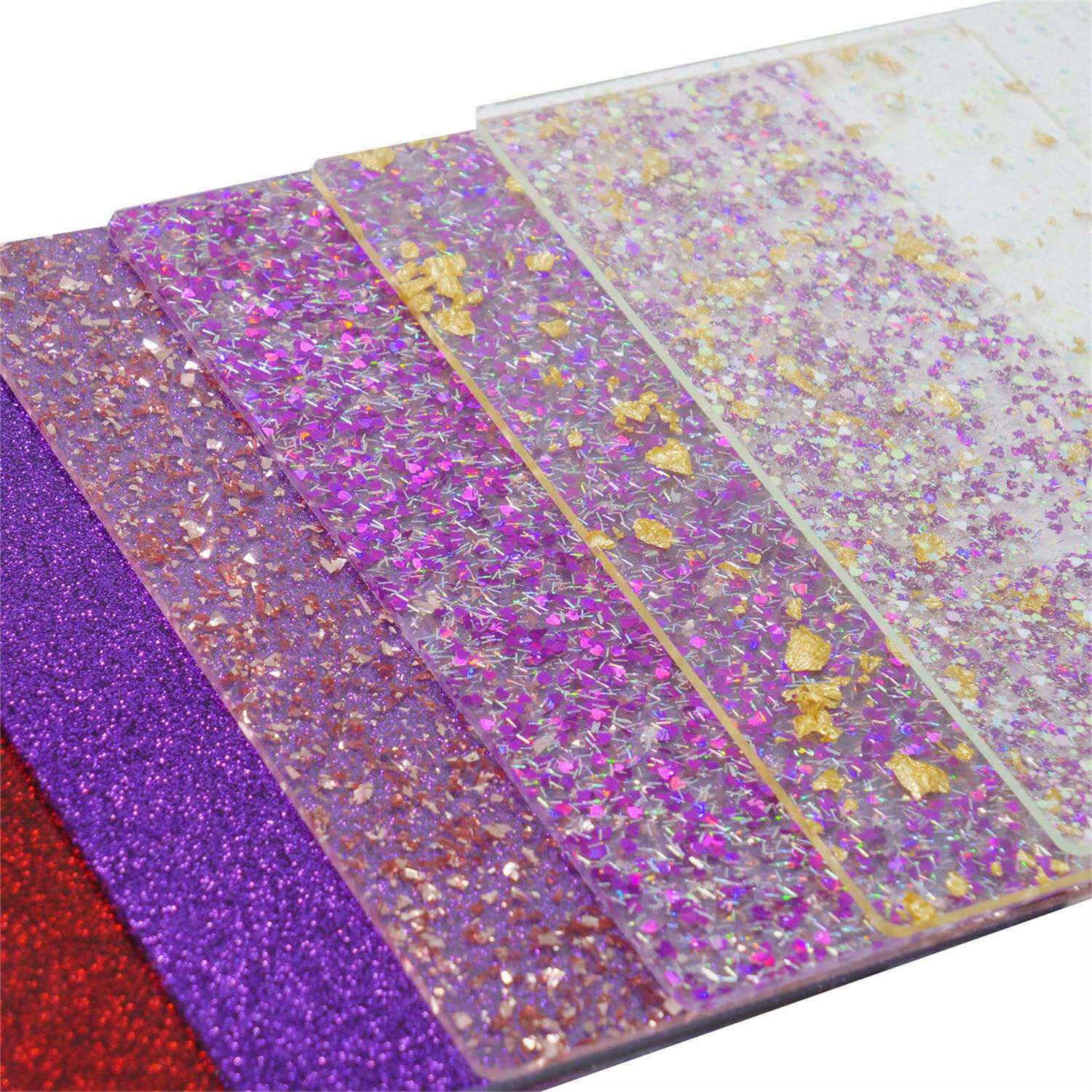

Particle Types and Reflective Properties

Various glitter particle types contribute to the unique visual characteristics of each glitter acrylic sheet variant. Metallic particles create bold, highly reflective surfaces that catch and redirect light with maximum intensity. Holographic particles produce rainbow-like color shifts depending on viewing angle and lighting conditions, adding dynamic visual interest to any application.

Iridescent particles offer subtle color variations that change based on environmental lighting, creating sophisticated visual effects suitable for upscale interior design applications. The particle size distribution within each glitter acrylic sheet determines the overall texture and light-scattering properties, with finer particles producing more uniform sparkle and larger particles creating dramatic light catching points.

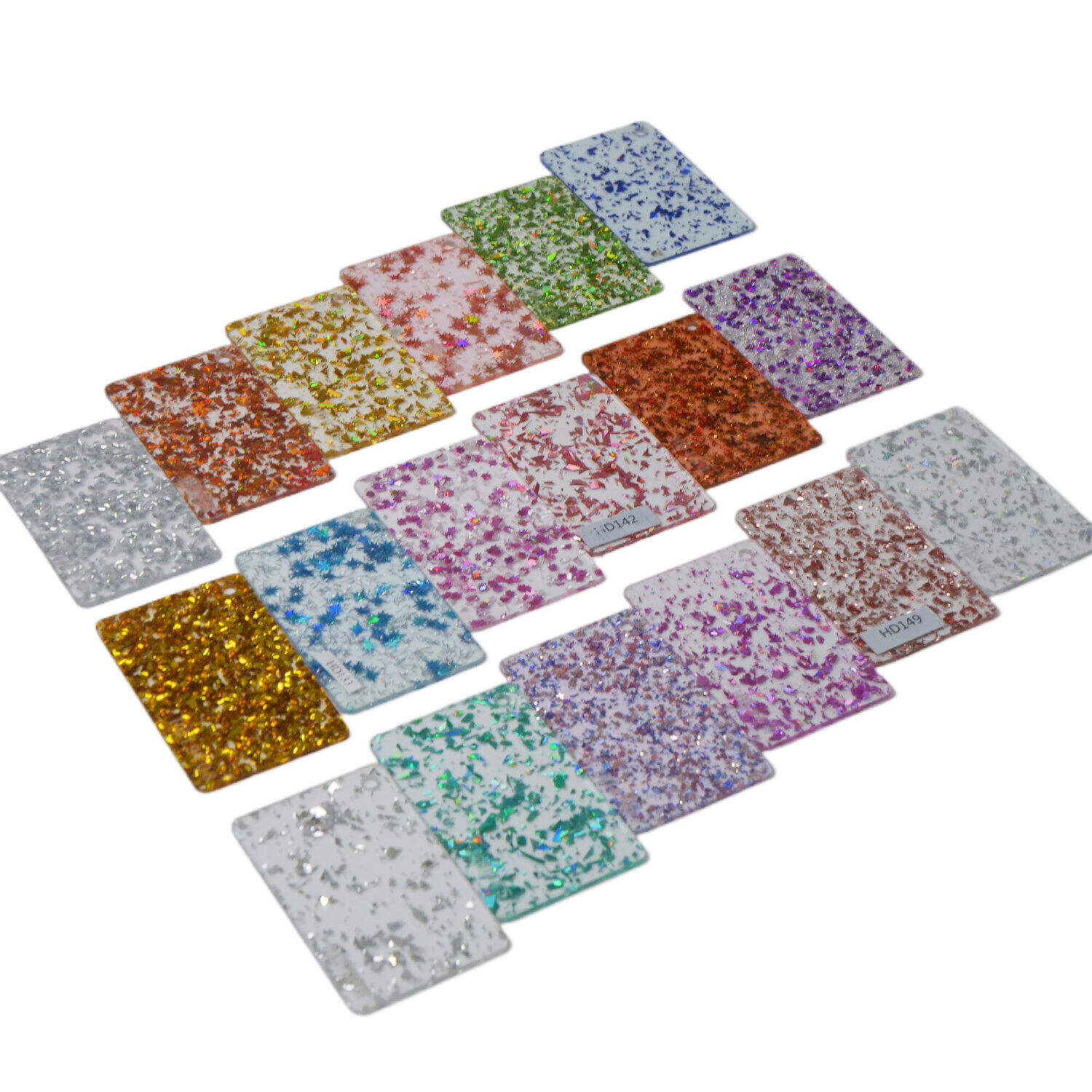

Color Palette Variations

Classic Metallic Finishes

Traditional metallic colors represent the foundation of glitter acrylic sheet collections, offering timeless appeal for both contemporary and classic design schemes. Gold variants range from warm, rich tones reminiscent of precious metals to bright, contemporary interpretations that complement modern architectural elements. Silver options provide cool, sophisticated aesthetics that work exceptionally well in commercial environments and high-tech applications.

Bronze and copper tones add warmth and earthiness to glitter acrylic sheet selections, creating connections with natural materials while maintaining the practical advantages of synthetic substrates. These metallic finishes demonstrate excellent color stability under various lighting conditions, ensuring consistent appearance throughout the product lifecycle. The depth of metallic effects varies based on particle concentration and base material transparency.

Vibrant Spectrum Colors

Contemporary glitter acrylic sheet collections include an extensive range of vibrant colors designed to meet diverse aesthetic requirements. Red variants span from deep crimson to bright cherry, offering options for applications ranging from dramatic accent pieces to subtle decorative elements. Blue selections include everything from royal navy to electric turquoise, providing versatility for both professional and creative applications.

Green options encompass forest tones, emerald shades, and lime variations that bring natural color palettes into interior spaces. Purple and pink variants offer sophisticated color choices for specialized applications where unique visual impact is desired. Each color maintains its vibrancy through advanced pigmentation techniques that resist fading and discoloration over extended periods.

Style Categories and Applications

Fine Glitter Compositions

Fine glitter acrylic sheet products feature small particle sizes that create subtle, refined sparkle effects suitable for professional environments and sophisticated design applications. The uniform distribution of micro-particles produces consistent light reflection across the entire surface without creating distracting hotspots or uneven visual patterns. These styles work particularly well in retail displays, office partitions, and architectural accent panels.

The manufacturing precision required for fine glitter acrylic sheet ensures that particle density remains consistent throughout each production batch. This consistency enables designers to specify materials with confidence, knowing that visual appearance will match expectations across multiple sheets. Fine glitter styles also demonstrate superior machinability, allowing for precise fabrication without particle loss or surface damage.

Chunky Glitter Variations

Chunky glitter styles incorporate larger reflective particles that create bold, dramatic visual effects ideal for statement pieces and attention-grabbing displays. These glitter acrylic sheet variants produce intense light reflection points that catch attention from significant distances, making them excellent choices for signage, exhibition displays, and decorative installations. The larger particle size creates more pronounced texture variations across the surface.

Despite their bold appearance, chunky glitter acrylic sheet products maintain the same structural integrity as their fine-glitter counterparts. The embedding process ensures that even large particles remain permanently fixed within the acrylic matrix, preventing particle migration or surface contamination. These materials require specialized handling techniques during fabrication to preserve particle integrity and surface finish quality.

Performance Characteristics

Optical Properties and Light Management

The optical performance of glitter acrylic sheet materials depends on multiple factors including particle type, concentration, and base material properties. Light transmission characteristics vary significantly based on these parameters, with some variants providing excellent clarity for applications requiring see-through capabilities while others prioritize maximum sparkle intensity. Understanding these optical relationships helps specifiers choose appropriate materials for specific lighting environments.

Refractive index matching between glitter particles and acrylic substrate influences overall optical clarity and sparkle intensity. Properly matched systems minimize unwanted light scattering while maximizing desired reflective effects. Advanced glitter acrylic sheet formulations incorporate optical enhancers that improve light gathering and redistribution properties, creating more dynamic visual experiences under varying lighting conditions.

Mechanical Durability and Weather Resistance

Structural performance characteristics of glitter acrylic sheet products match or exceed those of standard acrylic materials, ensuring reliable service in demanding applications. Impact resistance remains excellent despite particle inclusion, with proper embedding techniques maintaining material integrity under mechanical stress. Flexural strength properties enable use in applications requiring moderate bending or forming without compromising appearance or performance.

Weather resistance testing demonstrates that glitter acrylic sheet materials maintain their appearance and structural properties when exposed to UV radiation, temperature cycling, and moisture exposure. The embedded particle system remains stable under these conditions, preventing particle migration or surface degradation. This stability makes these materials suitable for both interior and exterior applications where long-term performance is critical.

Manufacturing and Processing Considerations

Fabrication Techniques and Tool Requirements

Processing glitter acrylic sheet materials requires specialized techniques and tooling to preserve surface finish and particle integrity throughout fabrication operations. Cutting operations must utilize sharp, appropriate tooling to prevent particle pull-out or surface damage that could compromise appearance. Feed rates and cutting speeds require adjustment compared to standard acrylic processing to accommodate particle presence.

Drilling and routing operations present unique challenges when working with glitter acrylic sheet materials due to particle hardness and distribution. Specialized cutting fluids and chip evacuation systems help maintain surface quality during machining operations. Edge polishing techniques must account for particle exposure along cut edges, often requiring modified procedures to achieve desired finish quality.

Quality Control and Inspection Methods

Quality assurance protocols for glitter acrylic sheet production include visual inspection methods that evaluate particle distribution uniformity, color consistency, and surface finish quality. Automated inspection systems utilize advanced imaging technology to detect variations that might affect final appearance or performance. Statistical process control methods ensure that each production batch meets established specifications.

Performance testing protocols verify mechanical properties, optical characteristics, and environmental resistance parameters for each glitter acrylic sheet formulation. Accelerated aging tests simulate long-term exposure conditions to validate durability claims and establish appropriate application guidelines. These comprehensive testing programs ensure consistent quality across different color variants and style categories.

Design Applications and Creative Possibilities

Interior Design Integration

Interior design applications for glitter acrylic sheet materials span residential, commercial, and institutional projects where visual impact combines with practical functionality. Wall cladding systems utilize these materials to create accent features that add sparkle without overwhelming surrounding design elements. The light-weight nature of acrylic substrates simplifies installation while reducing structural loading requirements.

Furniture applications incorporate glitter acrylic sheet components as tabletops, decorative panels, and accent pieces that bring glamour to functional items. The material's ease of cleaning and maintenance makes it practical for high-use applications where appearance retention is important. Custom fabrication capabilities enable unique shapes and configurations that match specific design requirements.

Commercial and Display Applications

Retail environments utilize glitter acrylic sheet materials for point-of-purchase displays, product showcases, and brand presentation elements that attract customer attention. The material's ability to enhance lighting effects makes it valuable for creating memorable visual experiences that support marketing objectives. Durability characteristics ensure that displays maintain their impact throughout extended use periods.

Exhibition and trade show applications benefit from the lightweight, high-impact visual properties of glitter acrylic sheet materials. Modular display systems incorporating these materials create sophisticated brand presentations that stand out in competitive environments. The material's machinability enables rapid prototyping and custom fabrication for unique display concepts.

FAQ

What thickness options are available for glitter acrylic sheet materials

Glitter acrylic sheet products are commonly available in thicknesses ranging from 3mm to 25mm, with some manufacturers offering custom thickness options for specific applications. Thinner sheets work well for decorative overlays and light-duty applications, while thicker variants provide structural capability for load-bearing installations. The glitter particle distribution remains consistent across different thickness options.

How do glitter acrylic sheet materials perform in outdoor applications

High-quality glitter acrylic sheet products demonstrate excellent outdoor performance when properly specified and installed. UV-stabilized formulations resist color fading and particle degradation under prolonged sun exposure. Weather resistance testing shows minimal dimensional changes and maintained optical properties after extensive environmental exposure cycles.

Can glitter acrylic sheet be recycled at the end of its service life

Many glitter acrylic sheet formulations are compatible with standard acrylic recycling processes, though particle content may limit certain recycling applications. Clean material without adhesive residue or contamination typically qualifies for mechanical recycling into lower-grade applications. Manufacturers increasingly offer take-back programs to ensure responsible end-of-life material handling.

What maintenance procedures are recommended for glitter acrylic sheet installations

Routine cleaning of glitter acrylic sheet surfaces involves mild soap solutions and soft cloths to prevent scratching or particle damage. Avoid abrasive cleaners or scrubbing tools that could affect surface finish or particle integrity. Regular inspection for edge damage or surface scratches enables prompt repair before issues compromise overall appearance or performance.