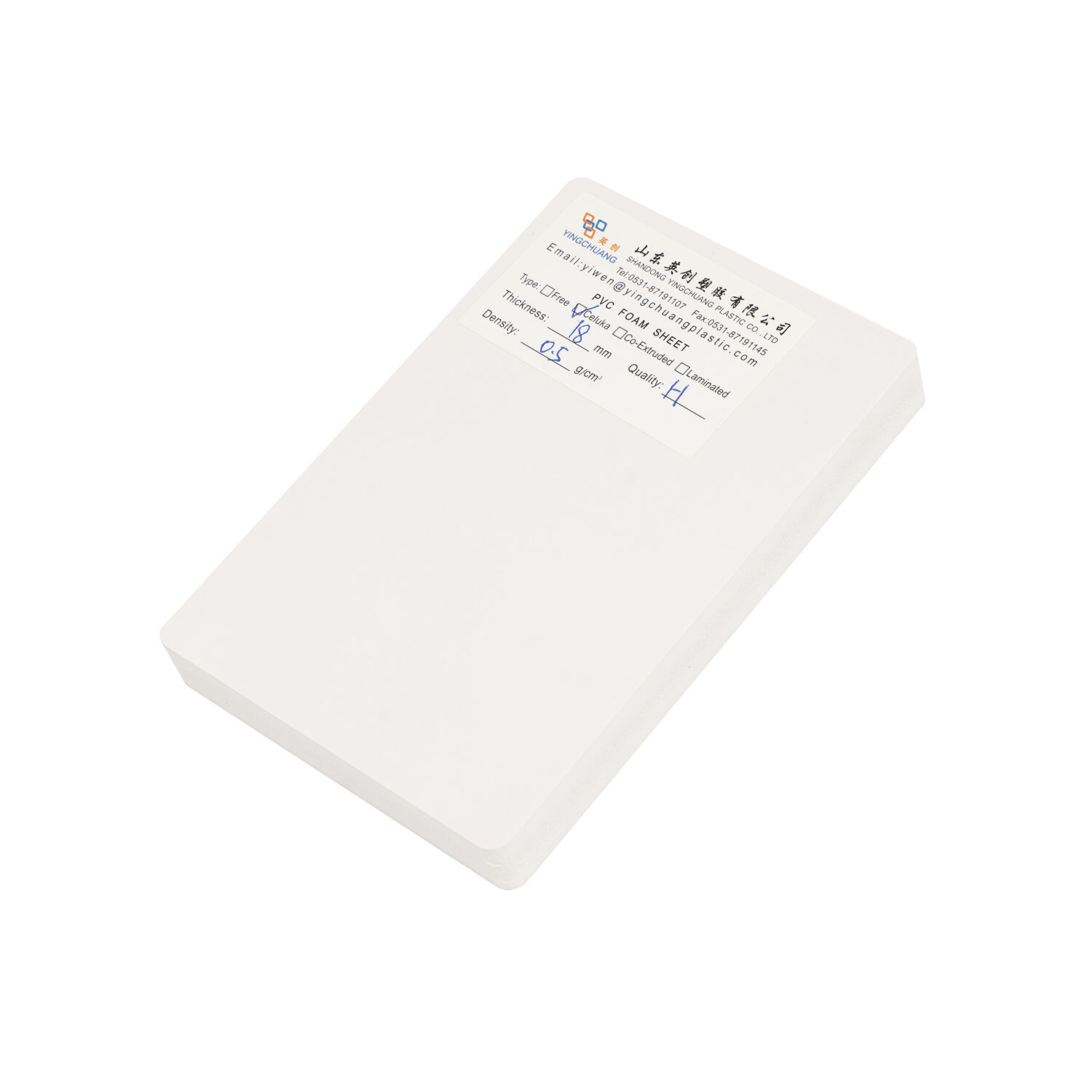

Versatility and Easy Processing

PVC extruded foam sheets offer unmatched versatility in processing and application methods, making them a preferred choice for diverse projects. The material can be easily cut, shaped, and formed using standard woodworking tools, eliminating the need for specialized equipment. This processing flexibility allows for on-site modifications and custom installations without compromising material integrity. The sheets accept various finishing techniques, including painting, laminating, and printing, enabling endless design possibilities. Their lightweight nature facilitates easy handling and installation, reducing labor costs and installation time. The material's consistent density and smooth surface finish ensure precise fabrication and high-quality end results. These processing advantages, combined with the material's inherent properties, make PVC extruded foam sheets suitable for applications ranging from construction and signage to industrial components and creative projects.