polycarbonate sheet embossed

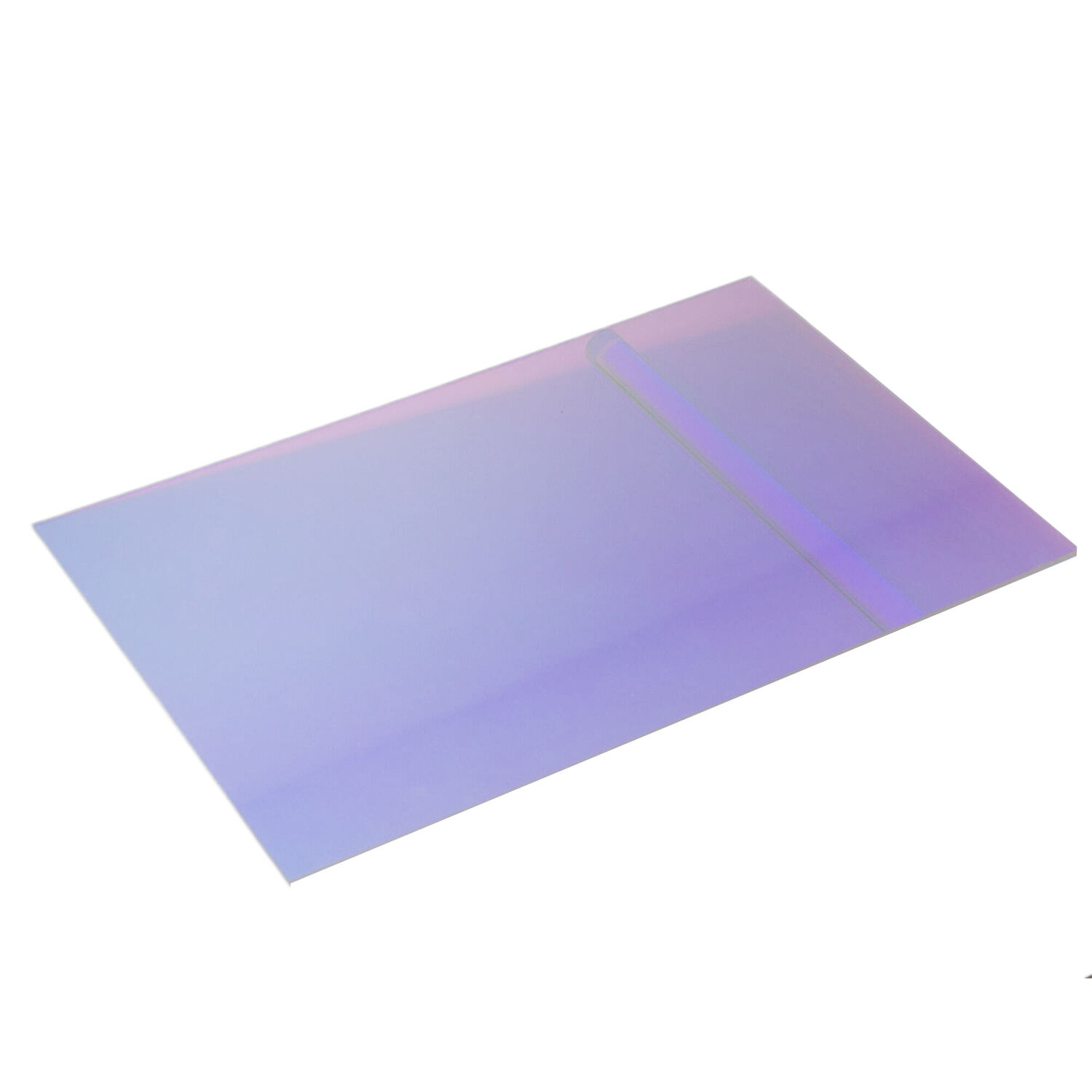

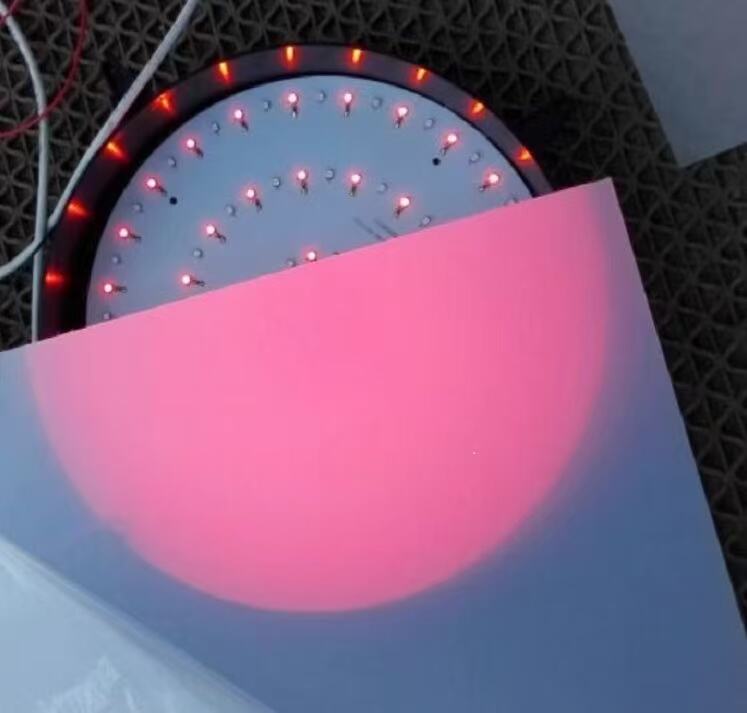

Polycarbonate sheet embossed represents a significant advancement in construction and architectural materials, combining durability with aesthetic appeal. This innovative material features a textured surface pattern created through a specialized embossing process, which enhances both its visual appeal and functional properties. The embossing process creates microscopic patterns on the sheet's surface, resulting in improved light diffusion, enhanced scratch resistance, and superior impact strength compared to standard polycarbonate sheets. These sheets are manufactured using high-grade polycarbonate resins and advanced embossing technology, ensuring consistent quality and long-term performance. The material offers exceptional versatility in applications, ranging from architectural glazing and greenhouse construction to industrial partitions and decorative panels. With UV protection integrated into its composition, embossed polycarbonate sheets maintain their clarity and structural integrity even after prolonged exposure to outdoor elements. The sheets are available in various thicknesses and patterns, allowing for customization according to specific project requirements, while maintaining their core characteristics of high impact resistance and excellent light transmission.