Yingchuang Ultra-Pure White PVDF Plastic Plate for Semiconductor and High-Purity Water Systems

- Overview

- Recommended Products

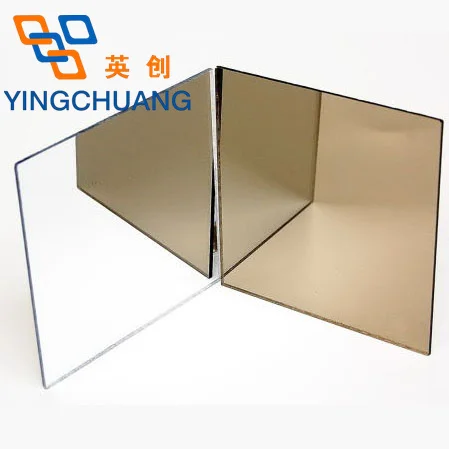

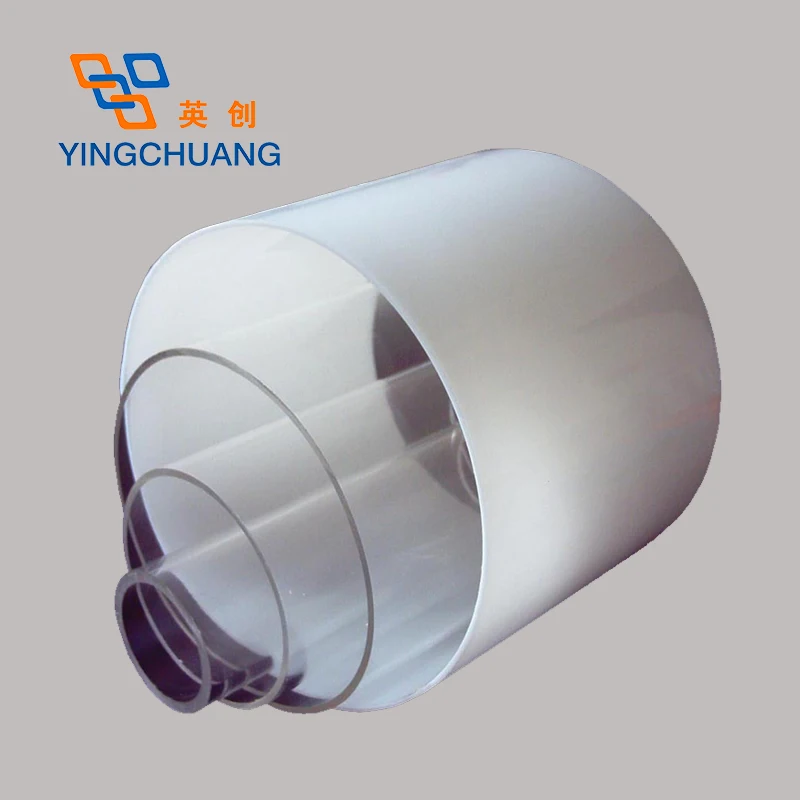

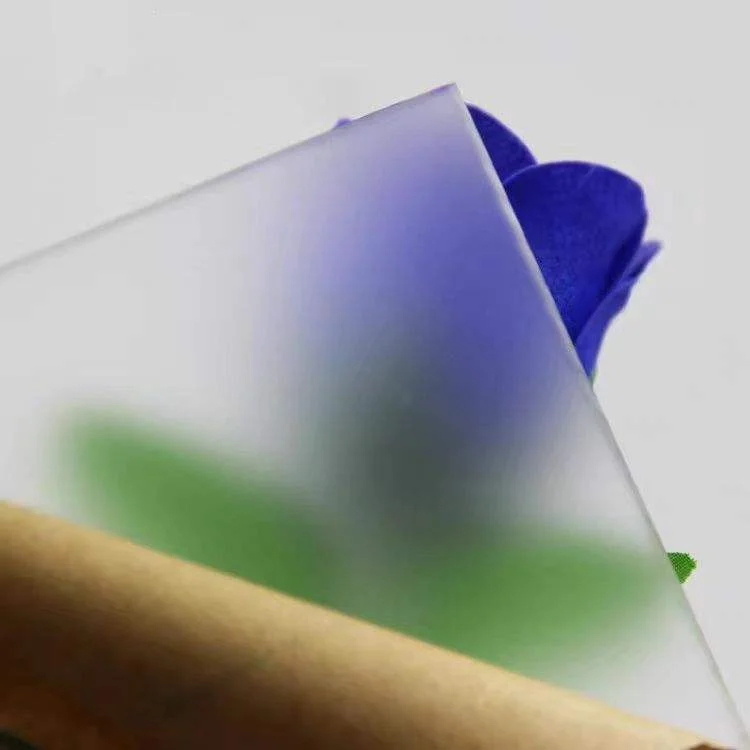

The PVDF board is a high-performance thermoplastic sheet made from polyvinylidene fluoride (Polyvinylidene Fluoride) through extrusion or molding processes. PVDF is a pure thermoplastic fluoropolymer that combines the characteristics of fluorine-based resins and general-purpose resins, and is known as one of the "plastic kings". Its stable molecular structure endows the final products with extremely excellent comprehensive performance.. PVDF sheet combines good mechanical, thermal and electrical properties with excellent chemical resistance. It has good resistance to UV, corrosion and radiation and can be used in food contact applications. It also has good wear resistance and sliding properties making it a versatile engineering material. PVDF board is a top-level high-performance engineering plastic sheet, renowned for its unparalleled chemical corrosion resistance, excellent weather resistance and UV resistance capabilities, as well as its extremely high purity. It can withstand the erosion of most strong acids, strong bases and solvents, far exceeding that of ordinary metals and plastics, ensuring long-term stable operation in harsh environments. At the same time, its inherent flame retardancy and excellent mechanical strength provide a solid guarantee for equipment and building safety. Whether it is the inner lining of chemical equipment, the ultra-pure fluid transportation in the semiconductor industry, or the exterior facade of landmark buildings, PVDF board is the ultimate material solution for extreme corrosion, high purity requirements and long-term outdoor durability, and is an indispensable ideal choice for high-end industrial applications.

|

|

|

| Item | Value | Unit |

| Density | 1.78 | g/cm |

| Water absorption | <0.4 | % |

| Crystal melting point | 171 | ℃ |

| Embrittlement temperature | <-61 | ℃ |

| Specific heat capacity | 1170 | J/JK·K |

| Linear expansion coefficient | 80*10 | K |

| Heat distortion temperature | 150 | ℃ |

| Decomposition temperature | 316 | ℃ |

| Operating temperature | -40 - 150 | ℃ |

| Pull strength | 49.2 | MPa |

| Elongation | 30-400 | % |

| Compressive strength | 70 | MPa |

| Impact strength | 1.47*10(4) | KI/M2 |

| Hardness | 7 | HB |

| Friction coefficient (to steel) | 0.14 | / |

| Dielectric coefficient (60hz) | 8.4 | / |

| Electrical loss (60hz) | 0.05 | / |

| Volume resistance | 2*10 | Ω/cm |

| Breakdown strength | 10 | Kv/m |

| Arc resistance | 50-70 | S |

| Flammability | self-extinguishing | / |

| Chemical resistance | good | / |

1.Chemical industry: Used for manufacturing inner linings, plate linings, pipes, valves, pump components, seals, etc. for chemical storage tanks, and handling various highly corrosive chemicals.

2.Semiconductor and electronics industry: Used for manufacturing wet process equipment (such as acid tanks, solvent tanks), wafer carriers, high-purity chemical delivery system pipelines and valves, ensuring ultra-high purity and no pollution.

3.Environmental protection and water treatment: Used for manufacturing dust removal and dehumidification equipment, filter plates, filter membrane supports, etc., capable of withstanding corrosive exhaust gas and wastewater.

4.Food and Pharmaceutical Industry: Equipment components that come into contact with food or drugs, meeting the requirements of FDA and other relevant certifications.

5.Construction industry: As high-performance building membranes or decorative panels, they are used for the roofs or facades of large buildings such as airports and sports venues, being durable and aesthetically pleasing.

·Temperature: -30°C up to +150°C.

·Excellent resistance to UV and weathering.

·Very good electrical insulation properties.

·High purity and good resistance to chemicals.

·Good resistance to wear.

·Excellent weldability.

·FDA approved for contact with food.

Q1: What is PVDF?

A: PVDF (Polyvinylidene Fluoride) is a high-performance thermoplastic fluoropolymer known for its exceptional combination of chemical resistance, UV stability, mechanical strength, and high purity. PVDF sheets are semi-finished products made from this material, used in demanding industrial applications.

Q2: What are the main advantages of PVDF sheets over other plastics like PP or PVC?

A: PVDF vastly outperforms PP and PVC in several key areas:

Chemical Resistance: Handles a much wider range of strong acids, bases, and solvents.

Purity & Cleanability: Ideal for ultra-pure applications in semiconductor and food industries, where PP/PVC may leach additives.

UV & Weather Resistance: Naturally resistant to UV degradation and weathering without needing additives, ensuring long-term performance outdoors.

Flame Retardancy: PVDF is inherently flame-retardant (with a high LOI), while PP and PVC are combustible.

Q3: How does PVDF compare to PTFE (Teflon®)?

A: While both are superb fluoropolymers, they have key differences:

Chemical Resistance: PTFE has slightly broader chemical resistance and a higher continuous service temperature.

Mechanical Properties: PVDF has superior mechanical strength, rigidity, and abrasion resistance. It is much less prone to "cold flow" (deformation under load) than PTFE.

Processability: A major advantage of PVDF is that it can be easily welded and thermoformed using standard plastic fabrication equipment, while PTFE cannot be melt-processed in the same way and requires sintering.

Q4: What are the most common applications for PVDF sheets?

A: Their primary use is in corrosive and high-purity environments:

Chemical Processing: Tank linings, pipes, valves, and pumps.

Semiconductor Industry: Wet bench components, chemical baths, and high-purity fluid handling systems.

Architecture: Durable cladding and roofing membranes for buildings.

Food & Pharma: Equipment components requiring cleanability and compliance with regulations.

Water Treatment: Components in electrodialysis and filtration systems.

Q5: Can PVDF sheets be easily fabricated?

A: Yes, this is one of its significant benefits. PVDF can be machined (sawed, milled, drilled), welded (using hot air, speed welding, or butt welding), and thermoformed efficiently using standard workshop equipment, allowing for the creation of complex custom parts.

Q6: Is PVDF material safe? Does it meet regulatory standards?

A: Absolutely. Our PVDF sheets are manufactured from resins that comply with key international standards for safety and purity, including:

FDA (U.S. Food and Drug Administration) regulations for repeated food contact.

EU 10/2011 regulations for food contact materials.

USP Class VI (United States Pharmacopeia) for medical and pharmaceutical applications.

They are also inherently flame-retardant and produce low smoke.

Q7: Why is PVDF more expensive than many other plastics?

A: The higher cost is due to the advanced chemical synthesis process of the raw PVDF polymer and its superior performance characteristics. The investment is justified by its longer service life, reduced maintenance costs, and prevention of costly downtime in critical applications. It provides excellent long-term value and ROI by protecting expensive equipment and processes.

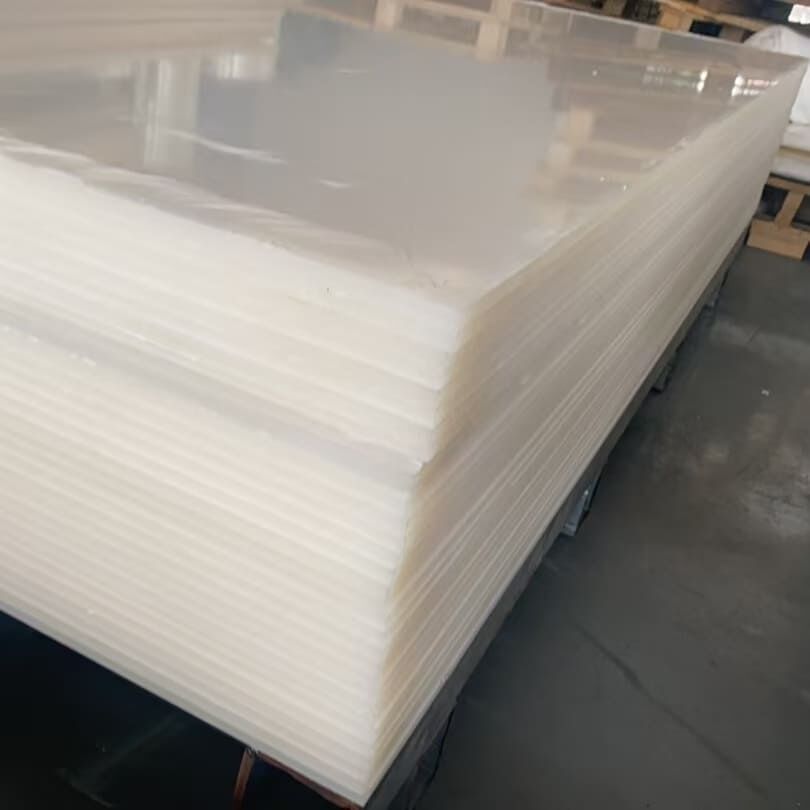

Q8: Do you offer custom sizes and thicknesses?

A: Yes. We provide a wide range of standard sizes and thicknesses to meet various needs. Furthermore, we offer custom cutting and fabrication services to deliver precision components ready for installation, saving you time and production costs.

Q9: How can I request a quote or get a sample?

A: We encourage you to test our material for yourself. Please visit our Contact Us page and fill out the form with your requirements (desired size, thickness, application). Our sales team will promptly provide a competitive quotation and arrange for a free sample to be sent to you.