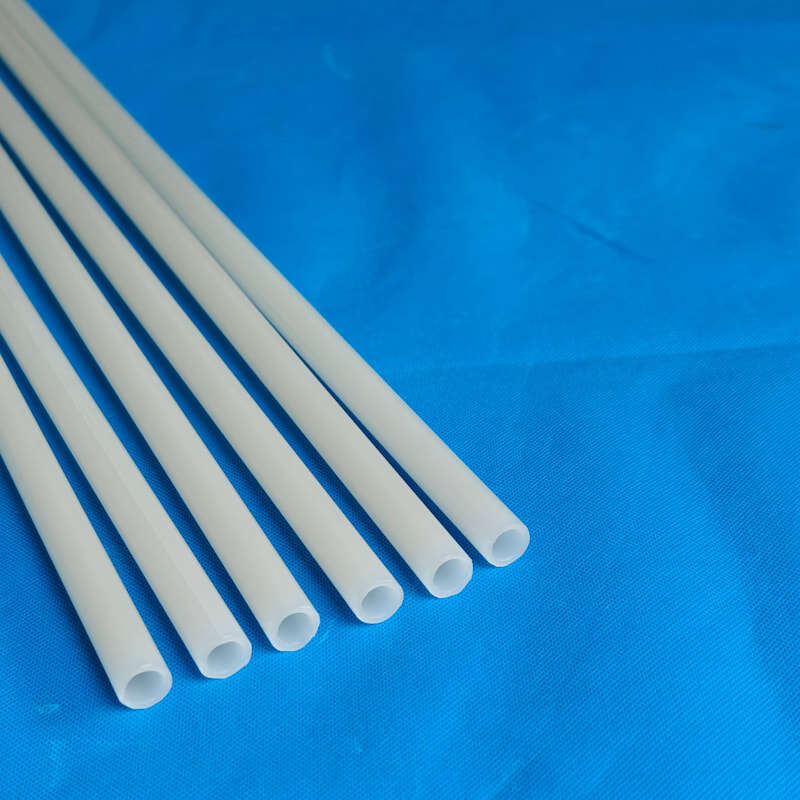

Yingchuang Industrial Grade PVDF Pipe with Superior Chemical Resistance for Aggressive Fluid Transfer

- Overview

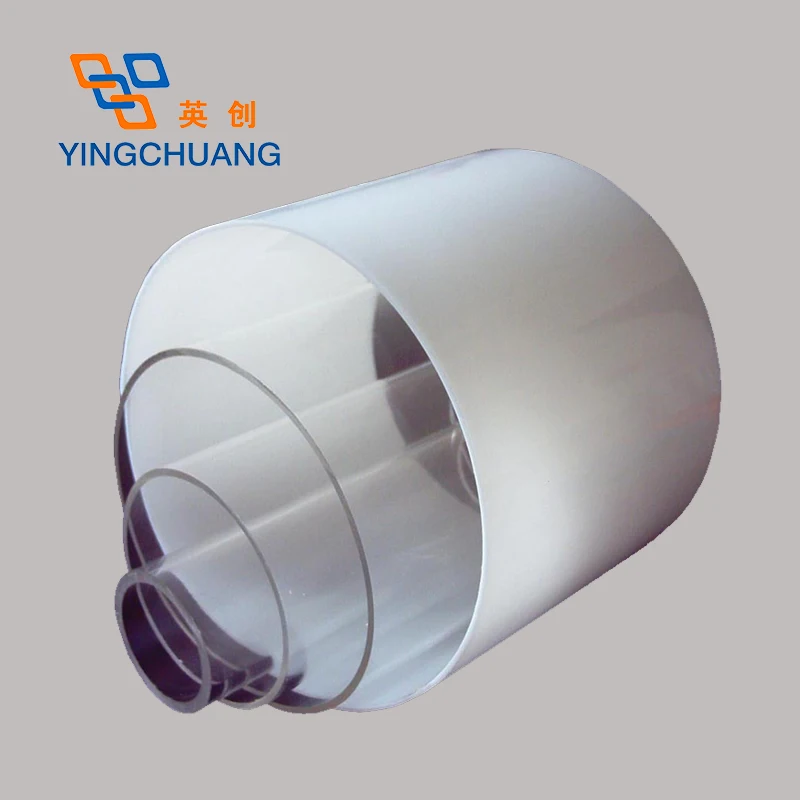

- Recommended Products

PVDF pipe is a high-performance engineering plastic pipe made of polyvinylidene fluoride (Polyvinylidene Fluoride) material. It has excellent chemical corrosion resistance and can withstand strong acids, strong bases, organic solvents, and halogens - almost all harsh chemical media. Its corrosion resistance even exceeds that of metal materials such as stainless steel. At the same time, PVDF pipe also has the advantages of high purity, no medium contamination, high mechanical strength, good resistance to ultraviolet aging, and good flame retardancy. It also complies with safety standards for food and pharmaceutical industries such as FDA and EU.

Due to its stable chemical properties and purity, PVDF pipes are widely used in semiconductor ultra-pure water systems, chemical industry conveying pipelines, food and pharmaceutical process equipment, environmental water treatment, and electroplating fluid conveying, etc. It is a reliable pipe material that can maintain a long service life even in harsh environments.

|

|

|

|

| Item | Value | Unit |

| Density | 1.78 | g/cm |

| Water absorption | <0.4 | % |

| Crystal melting point | 171 | ℃ |

| Embrittlement temperature | <-61 | ℃ |

| Specific heat capacity | 1170 | J/JK·K |

| Linear expansion coefficient | 80*10 | K |

| Heat distortion temperature | 150 | ℃ |

| Decomposition temperature | 316 | ℃ |

| Operating temperature | -40 - 150 | ℃ |

| Pull strength | 49.2 | MPa |

| Elongation | 30-400 | % |

| Compressive strength | 70 | MPa |

| Impact strength | 1.47*10(4) | KI/M2 |

| Hardness | 7 | HB |

| Friction coefficient (to steel) | 0.14 | / |

| Dielectric coefficient (60hz) | 8.4 | / |

| Electrical loss (60hz) | 0.05 | / |

| Volume resistance | 2*10 | Ω/cm |

| Breakdown strength | 10 | Kv/m |

| Arc resistance | 50-70 | S |

| Flammability | self-extinguishing | / |

| Chemical resistance | good | / |

Chemical Processing: Transfer lines for acids, alkalis, and solvents; vent systems; and effluent handling.

Ultra-Pure Water (UPW) Systems: High-purity water distribution in semiconductor, microelectronics, and pharmaceutical manufacturing.

Pharmaceutical & Bio-Tech: Process piping for purified water, water-for-injection (WFI), and chemical transfer under cGMP standards.

Food & Beverage: Product transfer lines, dairy processing, and brewing systems where cleanliness and compliance are critical.

Surface Treatment & Electroplating: For transporting aggressive chemical baths and filtration systems.

Environmental & Wastewater Treatment: Handling corrosive gases, effluents, and in electrodialysis systems.

·Exceptional Chemical Resistance

·Ultra-High Purity & Low Contamination.

·Excellent Mechanical Strength & Durability.

·Lightweight & Easy Installation.

·Long-Term Weathering & UV Stability.

1. What is a PVDF pipe?

A PVDF pipe is an engineering plastic pipe made of polyvinylidene fluoride (Polyvinylidene Fluoride). It has excellent chemical corrosion resistance, high purity, UV resistance and mechanical strength, and is widely used for fluid transportation in harsh industrial environments.

2. What are the main advantages of PVDF pipes?

Chemical corrosion resistance: Capable of withstanding strong acids, strong bases, solvents and halogens.

High purity and cleanliness: Does not contaminate the medium, complies with FDA and EU standards, suitable for the food and pharmaceutical industries.

Lightweight and easy to install: The weight is much lower than that of metal pipes, and it supports various connection methods such as welding and flange connections.

Long-lasting durability: Resistant to UV rays and aging, with a long service life.

3. What industries can PVDF pipes be used in?

Chemical industry: Transporting corrosive chemicals (such as acids, bases, solvents).

Semiconductors and Electronics: Ultra-pure water system, high-purity liquid drug transportation.

Food and Pharmaceuticals: Fluid transportation of food and pharmaceutical raw materials.

Environmental protection and water treatment: Wastewater treatment, electroplating solution transportation.

Energy sector: Lithium battery electrolyte pipelines, etc.

4. How are PVDF pipes connected? Is it reliable?

They can be connected through methods such as hot-melt butt welding, electrofusion welding, or flange connection, forming a permanent and leak-free system. The welding strength can reach over 90% of the pipe's original strength, and the reliability is extremely high.

5. What is the maximum temperature and pressure that PVDF pipes can withstand?

Temperature range: Generally applicable from -40℃ to +140℃ (up to 150℃ for short periods).

Pressure resistance performance: Depending on the pipe specification (SDR value), the pressure resistance can reach PN10-PN16 (1.0-1.6 MPa) or even higher.

6. Is PVDF pipe suitable for outdoor use?

Yes, the PVDF material is inherently resistant to ultraviolet radiation and weathering. It will not become brittle or lose its performance when used outdoors for a long period of time.

7. Compared with stainless steel or other metal pipes, what are the advantages of PVDF pipes?

More resistant to chemical corrosion, especially suitable for handling halogens (such as chlorine gas, fluorine acid).

Light in weight, with low installation and maintenance costs.

It does not form deposits or breed bacteria, and the inner wall is smooth with low resistance.

It has excellent insulation properties and no additional anti-corrosion treatment is required.

8. Are the PVDF pipes in compliance with food and drug safety standards?

They fully meet the standards of FDA (US Food and Drug Administration), EU 10/2011 (EU food contact materials), and USP Class VI (pharmaceutical grade).

9. How to select the specifications of PVDF pipes?

The diameter (DN), wall thickness (SDR value), and connection method of the pipeline should be determined based on the properties of the fluid, working pressure, temperature, and flow rate requirements. We offer technical parameter support for the selection.

10. Can you provide customized PVDF pipeline systems?

Yes, we support customizing pipeline dimensions, bending shapes, pre-assembled modules and matching valves and fittings, offering a one-stop solution.