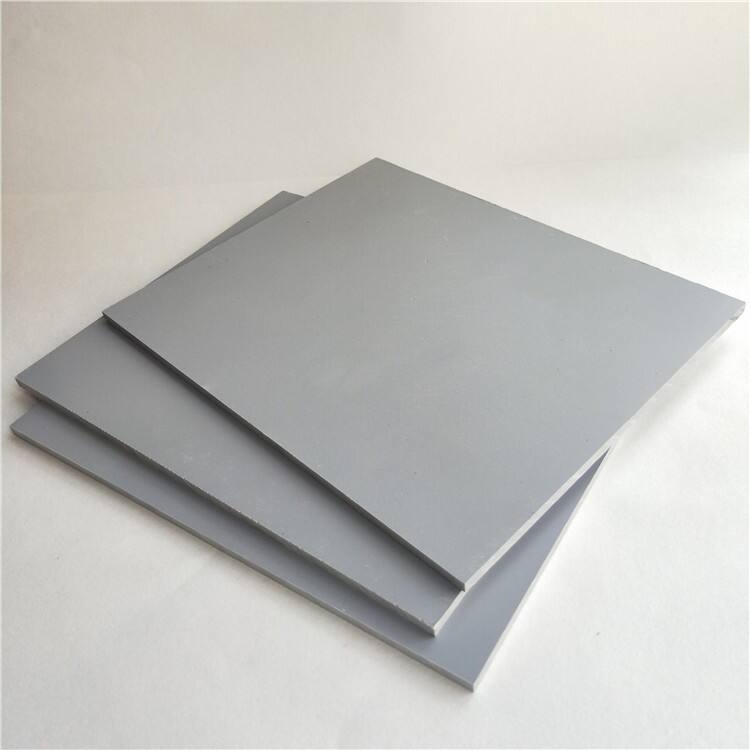

Industrial Grade PVC Plastic Sheet - Rigid, White, Multiple Sizes

Versatile Rigid PVC Sheet: The Lightweight, Easy-to-Fabricate Material for Countless Projects

Discover the ultimate utility material with our premium Rigid PVC Sheets. Combining remarkable lightweight properties with the workability of wood and the durability of plastic, these sheets are perfect for fabricators, builders, and DIY professionals. They offer excellent rigidity and impact strength while being significantly easier to handle and install than glass, metal, or stone.

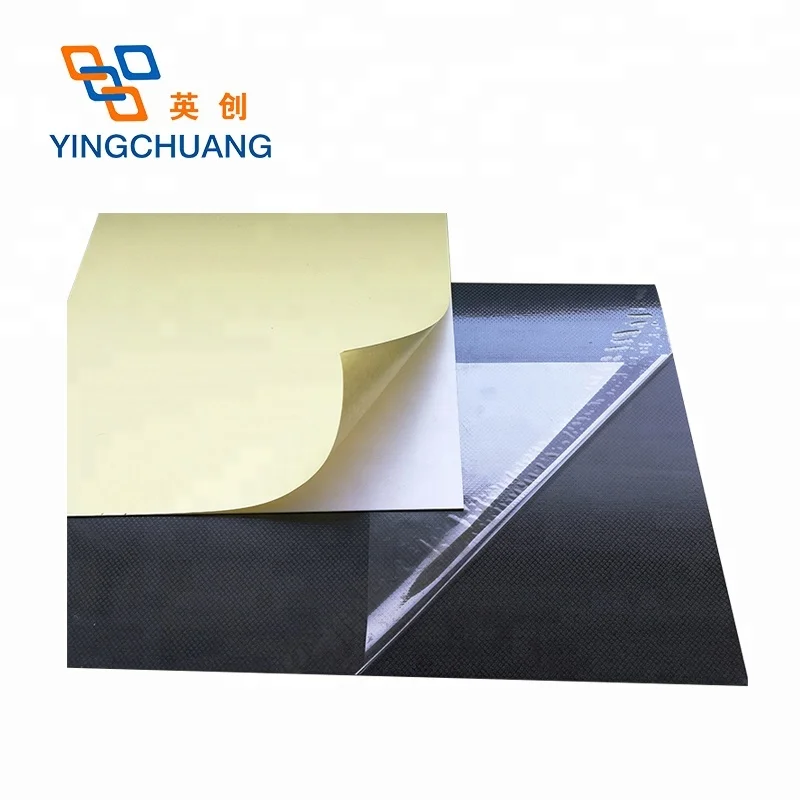

The smooth, non-porous surface is 100% waterproof, easy to clean, and resistant to stains and bacteria, making it highly suitable for hygiene-sensitive areas. It can be precisely cut, routed, drilled, and bent (with heat) using common carpentry and metalworking tools, enabling limitless design possibilities. As a cost-effective and low-maintenance material, it eliminates concerns about painting, sealing, or corrosion. Available in various colors and opaque finishes, it provides a clean, modern aesthetic for both functional and decorative purposes.

- Overview

- Recommended Products

Versatile Rigid PVC Sheet: The Lightweight, Easy-to-Fabricate Material for Countless Projects

Discover the ultimate utility material with our premium Rigid PVC Sheets. Combining remarkable lightweight properties with the workability of wood and the durability of plastic, these sheets are perfect for fabricators, builders, and DIY professionals. They offer excellent rigidity and impact strength while being significantly easier to handle and install than glass, metal, or stone.

The smooth, non-porous surface is 100% waterproof, easy to clean, and resistant to stains and bacteria, making it highly suitable for hygiene-sensitive areas. It can be precisely cut, routed, drilled, and bent (with heat) using common carpentry and metalworking tools, enabling limitless design possibilities. As a cost-effective and low-maintenance material, it eliminates concerns about painting, sealing, or corrosion. Available in various colors and opaque finishes, it provides a clean, modern aesthetic for both functional and decorative purposes.

|

|

|

|

| Specifications: | Place of Origin: China |

| Brand Name: YINGCHUANG | |

| Thickness: 1mm to 32mm. | |

| Width: 1220mm, 1560mm, 2050mm, etc. | |

| Length: Customizable based on actual needs, with 2440mm and 3050mm being common. |

Signage & Displays • Point-of-Sale Fixtures • Food Service Areas • Window Liners • Agricultural & Marine Applications • Protective Wall Cladding • Model Making & Prototyping.

Practical Benefits of PVC Rigid Sheet for Fabricators & Projects:

Cost-Effective Material Alternative: Provides a durable and chemically resistant solution at a significantly lower cost than many engineered plastics (e.g., polycarbonate, HDPE) and metals like aluminum.

Easy Fabrication & Installation: Can be easily cut, routed, drilled, and thermoformed using standard woodworking and plastic fabrication tools, reducing labor time and specialist equipment needs.

Low Maintenance & Long Lifecycle: Requires no painting, sealing, or special coatings. It is easy to clean, does not rust or corrode, and offers a long service life with minimal upkeep, maximizing ROI.

Versatile Multi-Industry Application: A proven material across sectors including chemical processing (for tanks, linings), building & construction (for partitions, profiles), signage, and transportation.

Hygienic & Waterproof Nature: Its non-porous surface prevents moisture absorption and bacterial growth, making it suitable for food processing areas, cleanrooms, and sanitary wall cladding.

Q: How do I join large panels to create a seamless look?

A: The most common and strongest method is PVC solvent welding, which chemically fuses the material into a homogenous, leak-proof bond. For non-structural seams, compatible PVC adhesive can also be used.

Q: How does its cost and performance compare to materials like HDPE, acrylic, or aluminum composite panel?

A: PVC rigid sheet offers a favorable balance of cost, flame retardancy, and rigidity. It is more rigid and fire-resistant than HDPE, more chemical resistant and affordable than acrylic, and easier to fabricate than most metals while being naturally corrosion-proof.

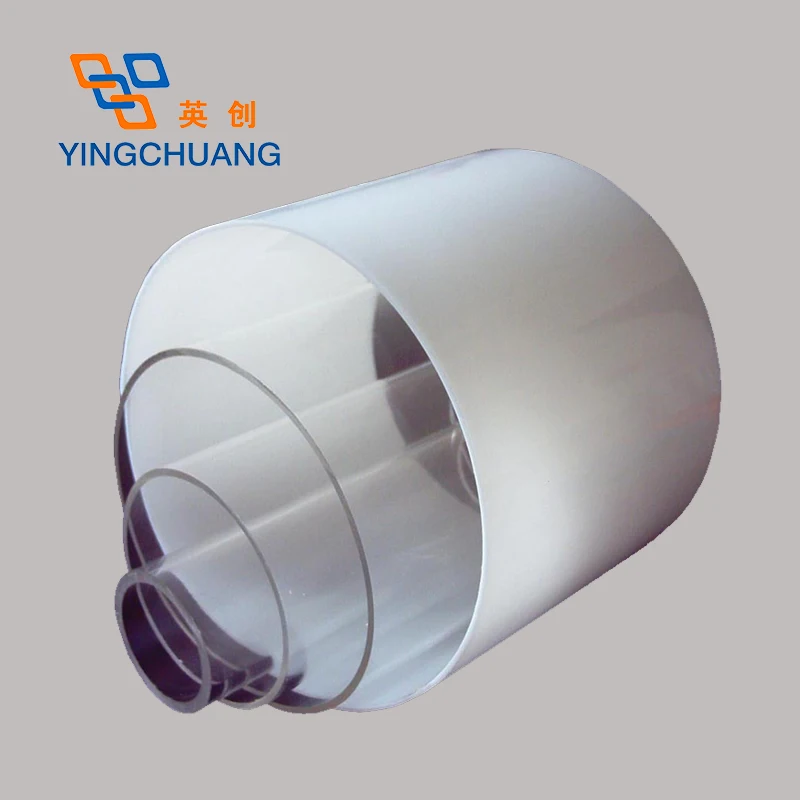

Q: Is there a recommended method for thermoforming rigid PVC sheet into 3D shapes?

A: Yes, it can be thermoformed. The sheet must be heated uniformly to 280-320°F (140-160°C) until pliable, then quickly formed over a mold using vacuum or pressure. Special "high-heat" grades are available for more complex, deep-draw forming.