Custom Size Polystyrene Foam Board - Lightweight & Rigid for Signage & Models

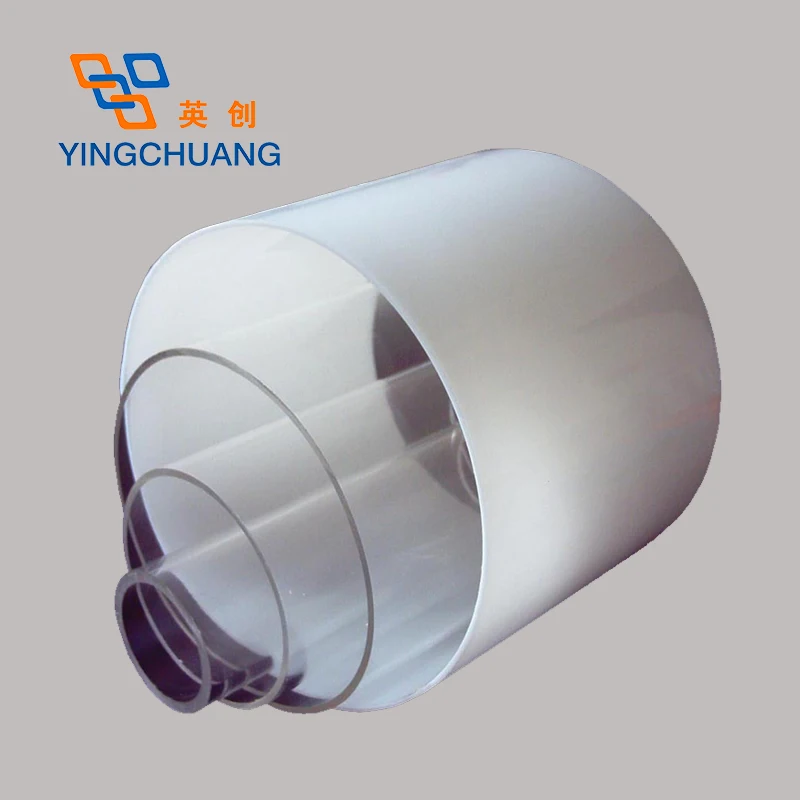

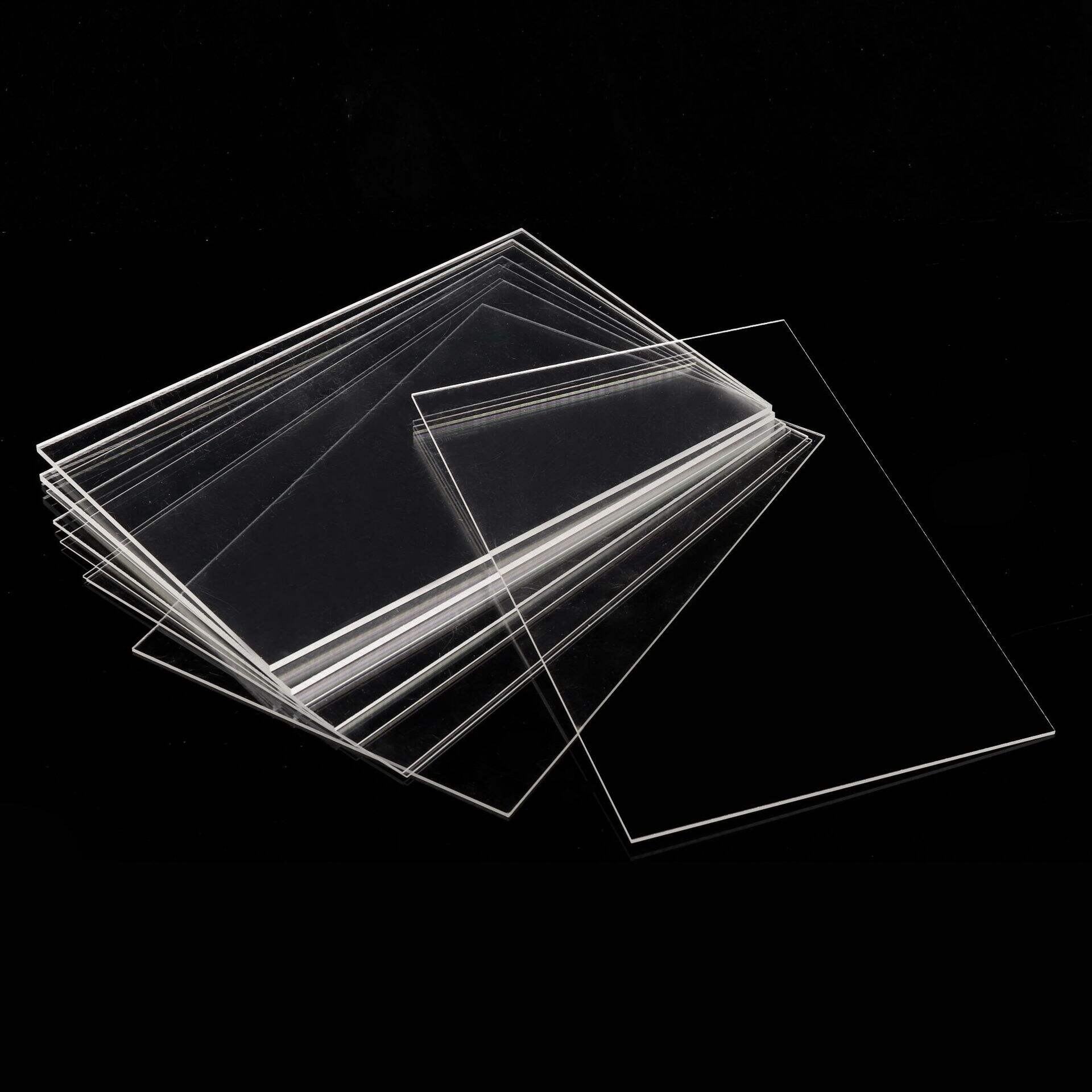

Our premium Polystyrene (PS) Sheets are engineered for exceptional performance across a wide range of applications. Available in both General Purpose (GPPS) crystal-clear and High-Impact (HIPS) opaque white formulations, these sheets offer an outstanding balance of clarity, rigidity, and ease of fabrication. As a cost-effective alternative to more expensive plastics like acrylic or polycarbonate, our PS sheets are the ideal choice for prototyping, packaging, displays, and countless DIY projects.

- Overview

- Recommended Products

Our premium Polystyrene (PS) Sheets are engineered for exceptional performance across a wide range of applications. Available in both General Purpose (GPPS) crystal-clear and High-Impact (HIPS) opaque white formulations, these sheets offer an outstanding balance of clarity, rigidity, and ease of fabrication. As a cost-effective alternative to more expensive plastics like acrylic or polycarbonate, our PS sheets are the ideal choice for prototyping, packaging, displays, and countless DIY projects.

|

|

|

|

| Specifications: | Place of Origin: China |

| Brand Name: YINGCHUANG | |

| Thickness: 0.1mm to 60mm. | |

| Width: 1220mm, 1560mm, 2050mm, etc. | |

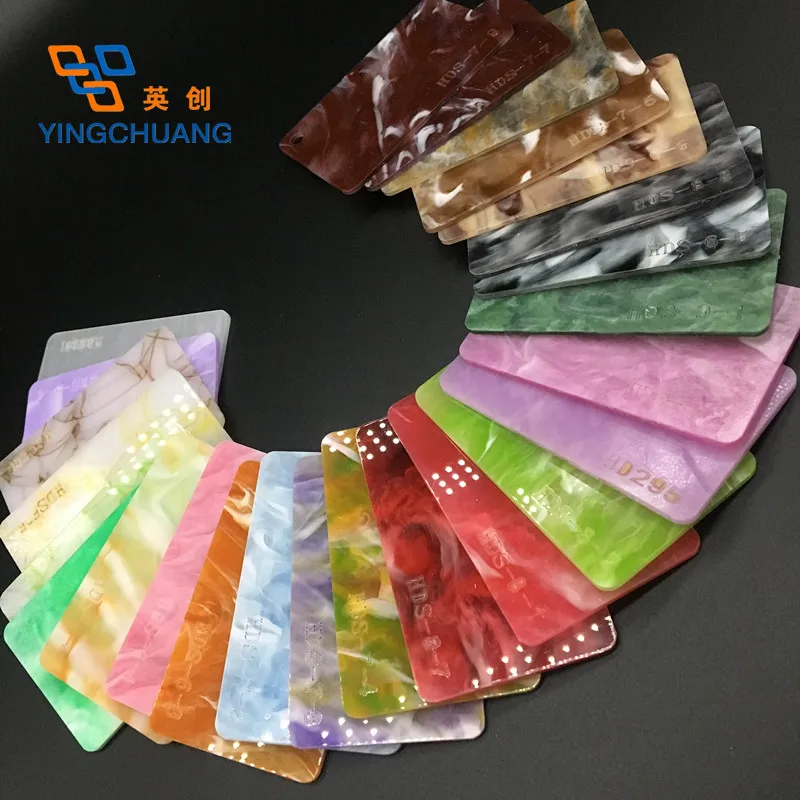

| Available Colors: Crystal Clear, Opaque White, Black, and Custom Colors upon request. |

Packaging: Blister packs, clamshells, and food-grade containers.

Displays & Signage: Point-of-purchase (POP) displays, decorative signs, and exhibition panels.

Prototyping & Models: Quick and affordable models for product design, architectural studies, and hobbyist projects.

Stationery & Office Supplies: Divider sheets, binder covers, and presentation folders.

DIY & Crafts: A versatile material for a multitude of creative and artistic endeavors.

Superior Clarity & Gloss (GPPS): The crystal-clear GPPS sheets feature excellent light transmission and a brilliant, glass-like surface, perfect for retail displays and packaging where visual appeal is paramount.

Excellent Fabrication Properties: Easily cut, routed, bent, and thermoformed. Our PS sheets can be seamlessly worked with standard woodworking and plastic fabrication tools, saving you time and production costs.

Lightweight & Rigid: Enjoy the benefits of a sturdy material that is easy to handle, transport, and install, reducing overall project weight.

Cost-Effective Solution: Achieve your project goals without exceeding your budget. Polystyrene delivers exceptional value without compromising on key performance characteristics.

1. Q: What is the difference between GPPS and HIPS sheets?

A: The main difference lies in flexibility and impact strength.

GPPS (General Purpose Polystyrene) is crystal clear and rigid but is more brittle and prone to cracking under impact.

HIPS (High Impact Polystyrene) is typically opaque white (and can be colored) because it's blended with a rubbery polymer additive. This makes it much more durable and resistant to shocks and breaks, hence the name "High Impact."

In short: Choose GPPS for superior clarity; choose HIPS for better durability.

2. Q: Can I cut and bend PS sheets easily?

A: Yes, that's one of the key advantages of Polystyrene! It is very easy to fabricate. You can cleanly cut it using a saw, utility knife, or laser cutter. It can also be easily bent and shaped using a strip heater for thermoforming projects. Always ensure you work in a well-ventilated area.

3. Q: How does Polystyrene (PS) compare to Acrylic (PMMA)?

A: Here’s a quick comparison:

Clarity: GPPS offers very good clarity, but Acrylic is typically clearer and more glass-like.

Strength & Impact Resistance: Acrylic is significantly stronger and more impact-resistant than standard GPPS. HIPS is tougher than GPPS but may still not match the impact resistance of acrylic.

Cost: PS is generally the more cost-effective option, making it ideal for budget-conscious projects, short-term displays, and prototyping.

Fabrication: Both are easy to cut, but PS is generally easier to thermoform.