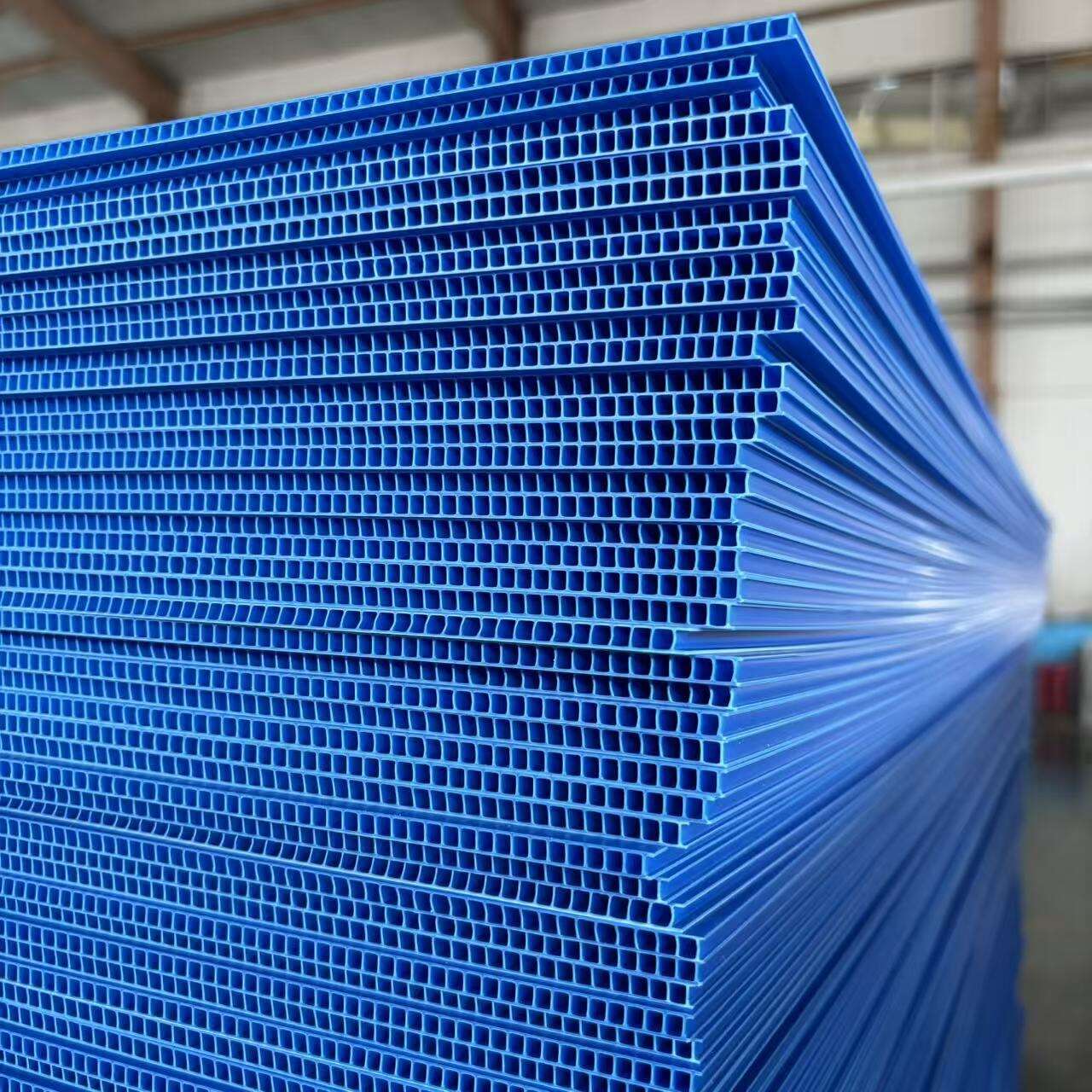

The construction and packaging industries are increasingly adopting sustainable materials that offer both environmental benefits and superior performance characteristics. Polypropylene hollow sheets have emerged as a revolutionary solution that addresses the growing demand for eco-friendly alternatives to traditional materials. These innovative plastic sheets combine lightweight construction with exceptional durability, making them an ideal choice for businesses seeking to reduce their environmental footprint while maintaining operational efficiency. The unique cellular structure of these sheets provides excellent insulation properties and structural integrity across diverse applications.

Manufacturing processes for polypropylene hollow sheets utilize advanced extrusion technologies that minimize waste generation and energy consumption. The thermoplastic nature of polypropylene allows for efficient recycling at the end of the product lifecycle, contributing to circular economy principles. Modern production facilities implement closed-loop systems that capture and reuse manufacturing byproducts, significantly reducing material waste. Quality control measures ensure consistent wall thickness and optimal cellular structure formation throughout the manufacturing process.

Environmental Impact Reduction Through Material Innovation

Carbon Footprint Minimization

Polypropylene hollow sheets demonstrate substantially lower carbon emissions during production compared to traditional materials such as wood, metal, or solid plastic alternatives. The manufacturing process requires approximately 30% less energy than conventional plastic sheet production due to the hollow core design requiring less raw material. Transportation costs and associated emissions are significantly reduced because of the lightweight nature of these sheets, with weight reductions of up to 50% compared to solid alternatives. Life cycle assessment studies indicate that pp hollow sheet applications can reduce overall project carbon footprints by 15-25% across various industrial sectors.

Resource Conservation Benefits

The hollow core structure maximizes material efficiency by providing structural strength while using minimal raw materials. This design philosophy aligns with sustainable manufacturing principles that prioritize resource optimization without compromising performance standards. Water consumption during the manufacturing process is significantly lower than wood processing or metal fabrication alternatives. The reduced material requirements translate directly into conservation of petroleum-based resources, supporting long-term sustainability goals for plastic manufacturers and end users alike.

Recyclability and Circular Economy Integration

End-of-Life Processing Advantages

Polypropylene belongs to thermoplastic polymer category, enabling multiple recycling cycles without significant degradation of mechanical properties. Specialized recycling facilities can process used sheets into new products, including outdoor furniture, automotive components, and industrial containers. The homogeneous material composition eliminates the complexity associated with composite material separation during recycling processes. Chemical recycling technologies are advancing to break down polypropylene into its constituent monomers, enabling infinite recycling potential for future applications.

Waste Stream Reduction

Implementation of polypropylene hollow sheets in packaging applications reduces overall waste generation through improved durability and reusability characteristics. The sheets can withstand multiple use cycles in protective packaging applications, significantly extending product lifespan compared to cardboard or foam alternatives. Post-industrial waste from manufacturing processes can be immediately reintroduced into production cycles, minimizing landfill contributions. The material's resistance to moisture, chemicals, and UV radiation extends service life, reducing replacement frequency and associated waste generation.

Energy Efficiency and Insulation Properties

Thermal Performance Characteristics

The air-filled cellular structure within polypropylene hollow sheets provides excellent thermal insulation properties that contribute to energy conservation in building applications. R-value measurements demonstrate superior insulation performance compared to solid plastic sheets of equivalent thickness. Building envelope applications utilizing these sheets can reduce heating and cooling energy consumption by 10-15% through improved thermal barrier performance. The low thermal conductivity properties make them ideal for cold storage facilities and temperature-controlled logistics applications.

Acoustic Insulation Benefits

Sound dampening characteristics of hollow core construction contribute to noise pollution reduction in urban environments and industrial settings. The cellular structure effectively absorbs and deflects sound waves, providing acoustic comfort in commercial and residential applications. Noise reduction coefficients exceed those of traditional building materials while maintaining lightweight construction advantages. Multi-layer configurations can achieve significant sound transmission class improvements for specialized acoustic applications.

Durability and Longevity Advantages

Weather Resistance Properties

Polypropylene hollow sheets exhibit exceptional resistance to environmental stressors including UV radiation, moisture, and temperature fluctuations. The inherent chemical stability of polypropylene prevents degradation from exposure to common environmental contaminants and pollutants. Surface treatments can further enhance weather resistance properties, enabling outdoor applications with service lives exceeding 10-15 years. The material maintains structural integrity across temperature ranges from -40°C to 80°C, supporting diverse geographical applications.

Chemical and Biological Resistance

The non-porous surface structure prevents bacterial growth and chemical penetration, supporting hygiene requirements in food processing and medical applications. Resistance to acids, alkalis, and organic solvents ensures compatibility with industrial cleaning protocols and harsh operating environments. The material does not support mold or mildew growth, eliminating the need for chemical treatments that could compromise environmental sustainability. Pest resistance characteristics prevent damage from insects and rodents that commonly affect organic materials.

Application Versatility and Performance

Construction Industry Applications

Temporary protection systems utilize polypropylene hollow sheets for floor protection, wall covering, and equipment shielding during construction phases. The sheets provide excellent impact resistance while maintaining easy installation and removal characteristics. Formwork applications benefit from the smooth surface finish and dimensional stability of these materials. Roofing underlayment applications leverage the waterproof properties and lightweight characteristics for improved installation efficiency.

Packaging and Logistics Solutions

Reusable packaging systems incorporate polypropylene hollow sheets for durable container construction and protective inserts. The material's shock absorption properties protect sensitive products during shipping and handling operations. Custom fabrication capabilities enable precise fitting for specialized packaging requirements across automotive, electronics, and pharmaceutical industries. Stackable container designs optimize warehouse space utilization while maintaining product protection standards.

Economic Benefits of Sustainable Material Choice

Cost-Effectiveness Analysis

Initial investment costs for polypropylene hollow sheets are typically competitive with traditional alternatives while providing superior long-term value through extended service life. Maintenance requirements are minimal due to the material's resistance to environmental degradation and mechanical damage. Labor costs for installation and handling are reduced due to the lightweight characteristics and ease of fabrication. Transportation cost savings accumulate over project lifecycles due to reduced shipping weights and volumes.

Return on Investment Considerations

Energy savings from improved insulation properties contribute to positive return on investment calculations for building envelope applications. Reduced replacement frequency extends asset utilization periods, improving overall project economics. Tax incentives and sustainability certifications may provide additional financial benefits for projects incorporating environmentally responsible materials. Corporate sustainability reporting benefits support brand value enhancement and market positioning advantages.

FAQ

What makes polypropylene hollow sheets more environmentally friendly than traditional materials

Polypropylene hollow sheets offer superior environmental benefits through reduced material consumption, lower manufacturing energy requirements, and complete recyclability. The hollow core design uses up to 50% less raw material while maintaining structural performance, and the thermoplastic nature enables infinite recycling cycles without property degradation.

How long do polypropylene hollow sheets typically last in outdoor applications

With proper surface treatments and UV stabilization, polypropylene hollow sheets can maintain structural integrity and appearance for 10-15 years in outdoor applications. The material's inherent weather resistance properties prevent degradation from moisture, temperature fluctuations, and environmental contaminants common in exterior installations.

Can polypropylene hollow sheets be recycled at standard recycling facilities

Most municipal recycling programs accept polypropylene materials, though specialized industrial recycling facilities provide optimal processing capabilities for hollow sheet products. The homogeneous material composition simplifies the recycling process, and many manufacturers offer take-back programs for post-consumer material recovery.

What industries benefit most from switching to polypropylene hollow sheets

Construction, packaging, automotive, and agricultural industries realize significant benefits from polypropylene hollow sheet adoption. These sectors particularly value the combination of environmental sustainability, cost-effectiveness, and performance characteristics that support both operational efficiency and corporate sustainability objectives.

Table of Contents

- Environmental Impact Reduction Through Material Innovation

- Recyclability and Circular Economy Integration

- Energy Efficiency and Insulation Properties

- Durability and Longevity Advantages

- Application Versatility and Performance

- Economic Benefits of Sustainable Material Choice

-

FAQ

- What makes polypropylene hollow sheets more environmentally friendly than traditional materials

- How long do polypropylene hollow sheets typically last in outdoor applications

- Can polypropylene hollow sheets be recycled at standard recycling facilities

- What industries benefit most from switching to polypropylene hollow sheets