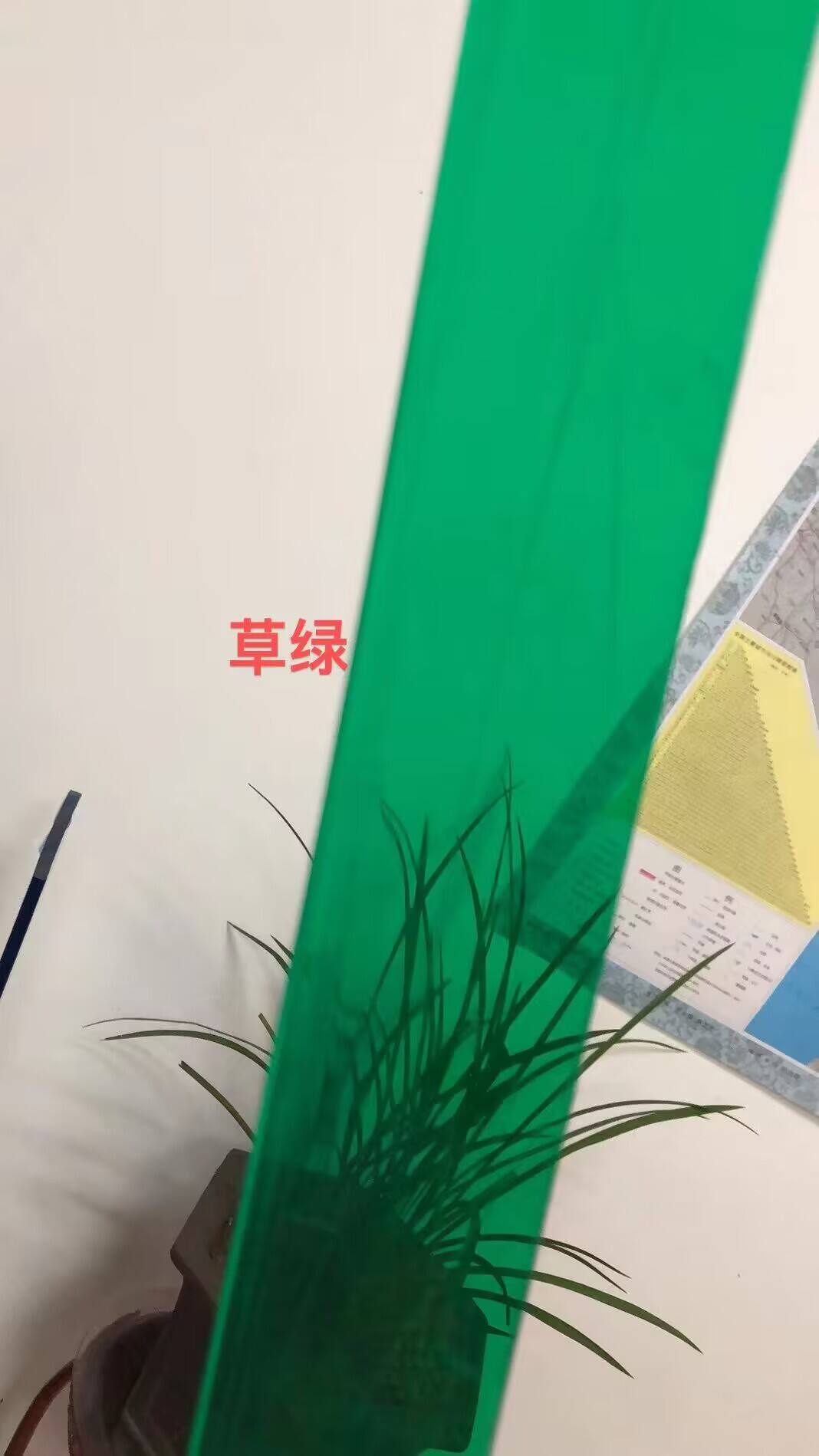

polycarbonate hollow sheet

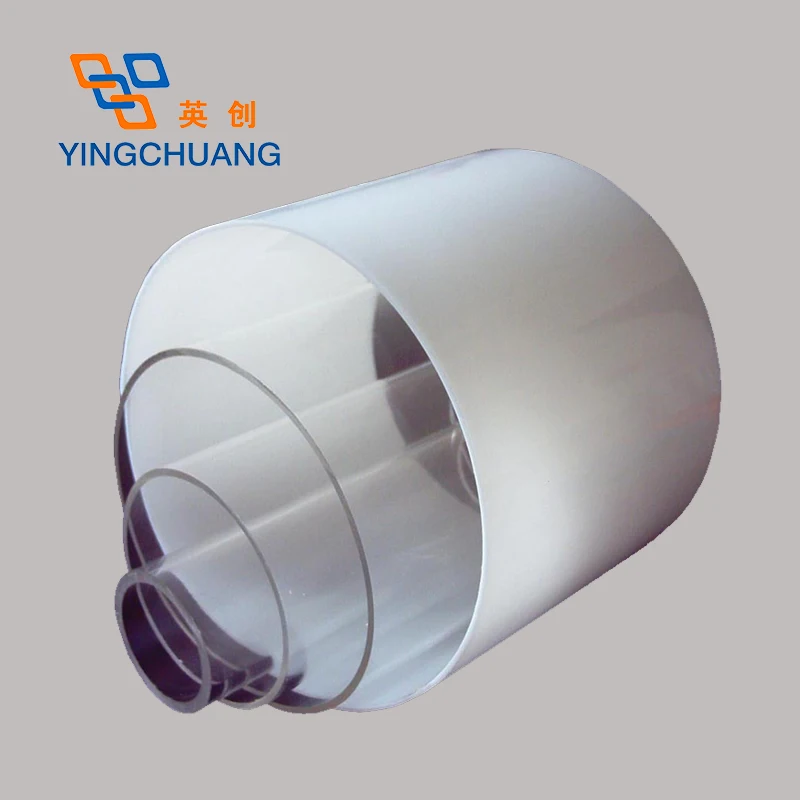

Polycarbonate hollow sheets are advanced building materials that combine lightweight construction with exceptional durability. These versatile sheets feature a multi-wall structure with hollow chambers that create superior insulation properties while maintaining remarkable strength. The sheets are manufactured through an advanced extrusion process, resulting in a product that offers both thermal efficiency and impact resistance. The hollow structure provides excellent light transmission while reducing heat loss, making it an ideal choice for various architectural applications. These sheets are available in different thicknesses and configurations, typically ranging from 4mm to 40mm, with varying numbers of walls to suit different requirements. The material's UV-protective layer ensures long-lasting performance and prevents yellowing over time. Polycarbonate hollow sheets are highly versatile and can be easily cut, bent, and installed, making them suitable for both commercial and residential applications. They excel in projects requiring natural light transmission while maintaining thermal insulation, such as greenhouses, skylights, roofing systems, and partition walls. The material's inherent fire-resistant properties and ability to withstand extreme weather conditions further enhance its appeal in construction applications.