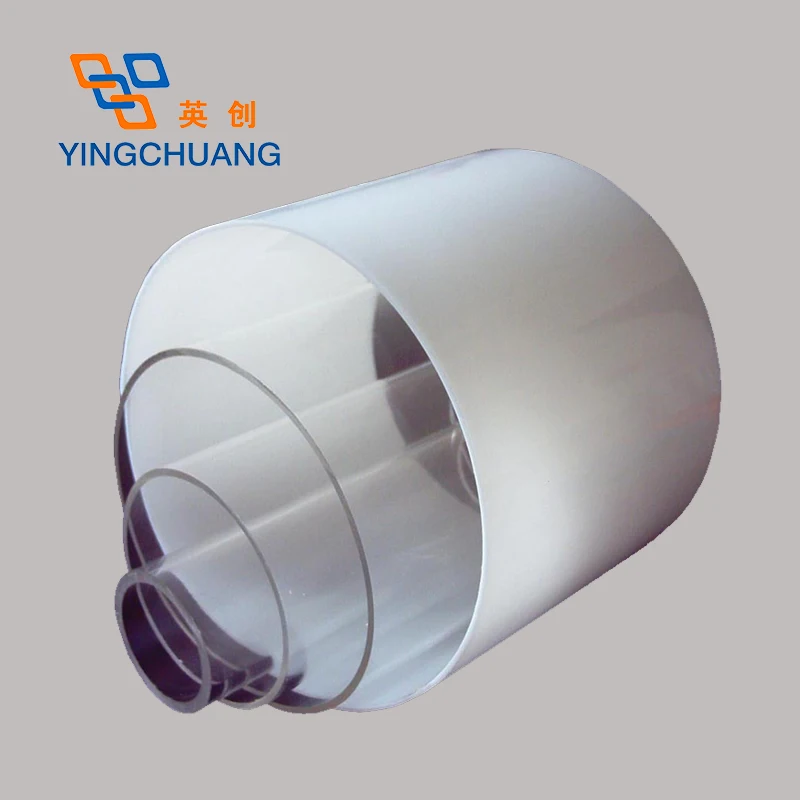

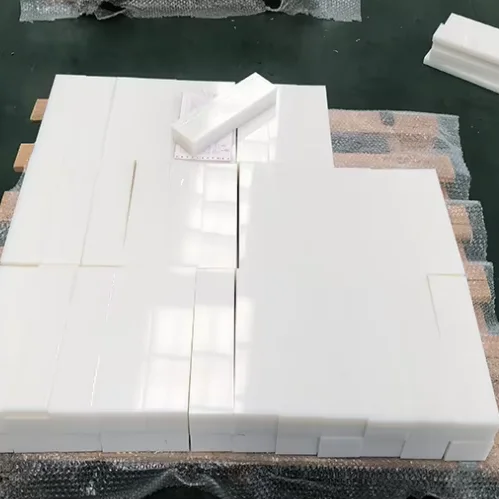

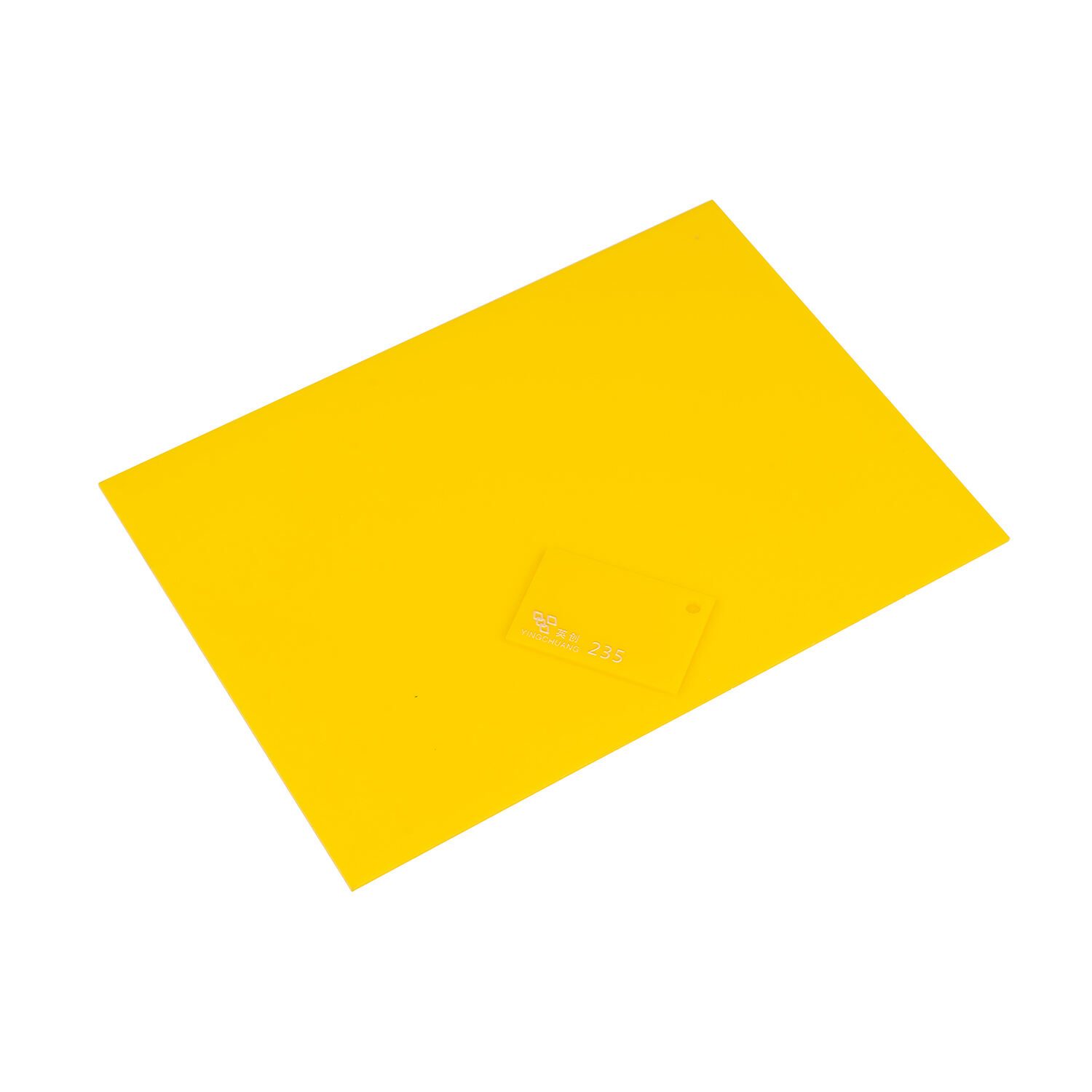

plexiglass sheets custom size

Plexiglass sheets custom size represents a versatile and highly adaptable solution in modern manufacturing and construction. These transparent acrylic sheets can be precisely cut and shaped according to specific dimensional requirements, offering unparalleled flexibility for various applications. The sheets are manufactured using advanced extrusion processes, ensuring consistent quality and optical clarity throughout each piece. With thicknesses ranging from 1mm to 25mm and the ability to be cut to any desired dimensions, these custom plexiglass sheets provide exceptional versatility for both commercial and residential projects. The material exhibits remarkable durability, featuring UV resistance and impact strength up to 17 times greater than traditional glass while maintaining only half the weight. The customization process employs state-of-the-art CNC machinery and laser cutting technology, guaranteeing precise dimensions and smooth edges. These sheets can be further enhanced with various surface treatments, including anti-glare coatings, scratch-resistant layers, and color tinting options, making them suitable for indoor and outdoor applications. The material's natural resistance to weathering and chemical exposure ensures long-lasting performance in diverse environments.