Versatile Design and Installation Capabilities

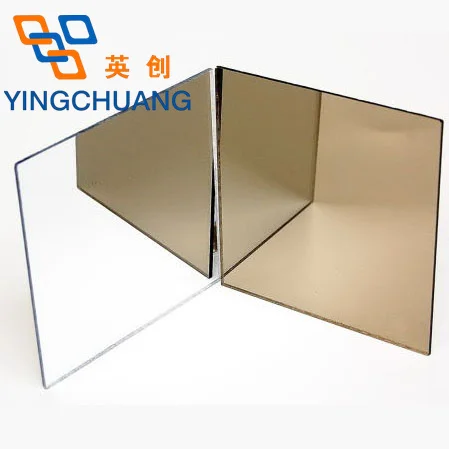

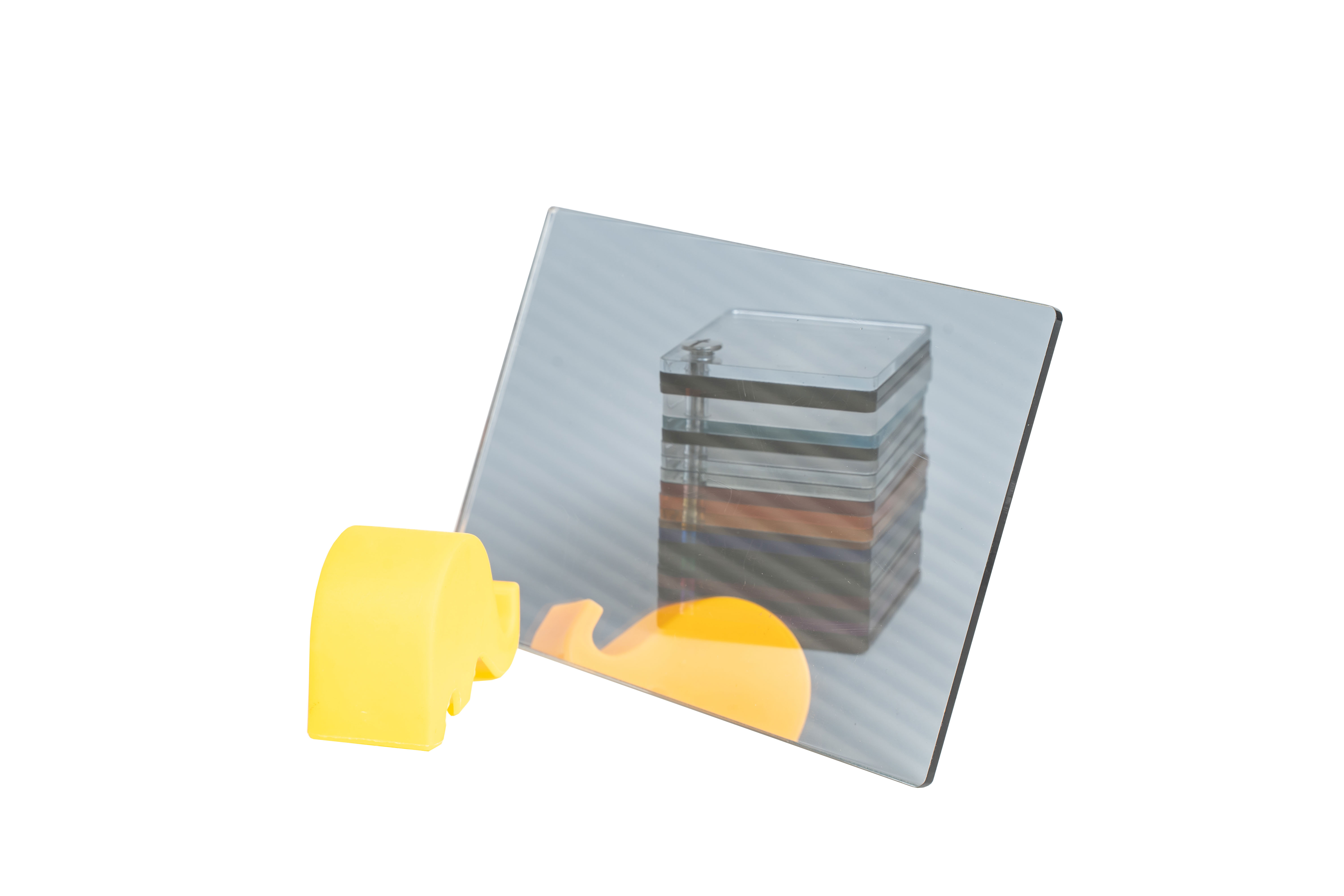

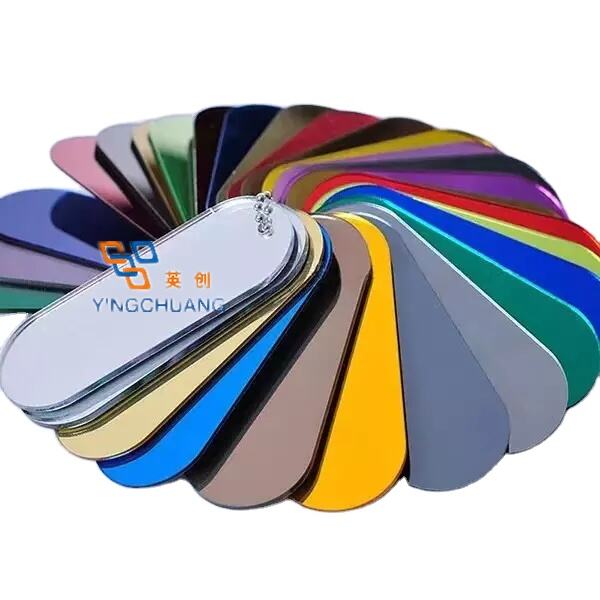

The mirror finish acrylic sheet demonstrates remarkable versatility in design applications, offering architects and designers unprecedented creative freedom. The material can be easily cut, shaped, and formed into various configurations without compromising its reflective properties, enabling the creation of unique architectural elements and custom installations. The sheets can be thermoformed to create curved surfaces, opening up possibilities for innovative design solutions that would be impossible with traditional glass mirrors. The lightweight nature of the material, combined with its flexibility in fabrication, simplifies the installation process significantly. Installers can work with the material using standard tools and techniques, reducing installation time and costs. The sheets can be mounted using various methods, including mechanical fasteners, adhesives, or custom mounting systems, providing flexibility in installation approaches. This versatility makes the material suitable for a wide range of applications, from retail displays to architectural features.