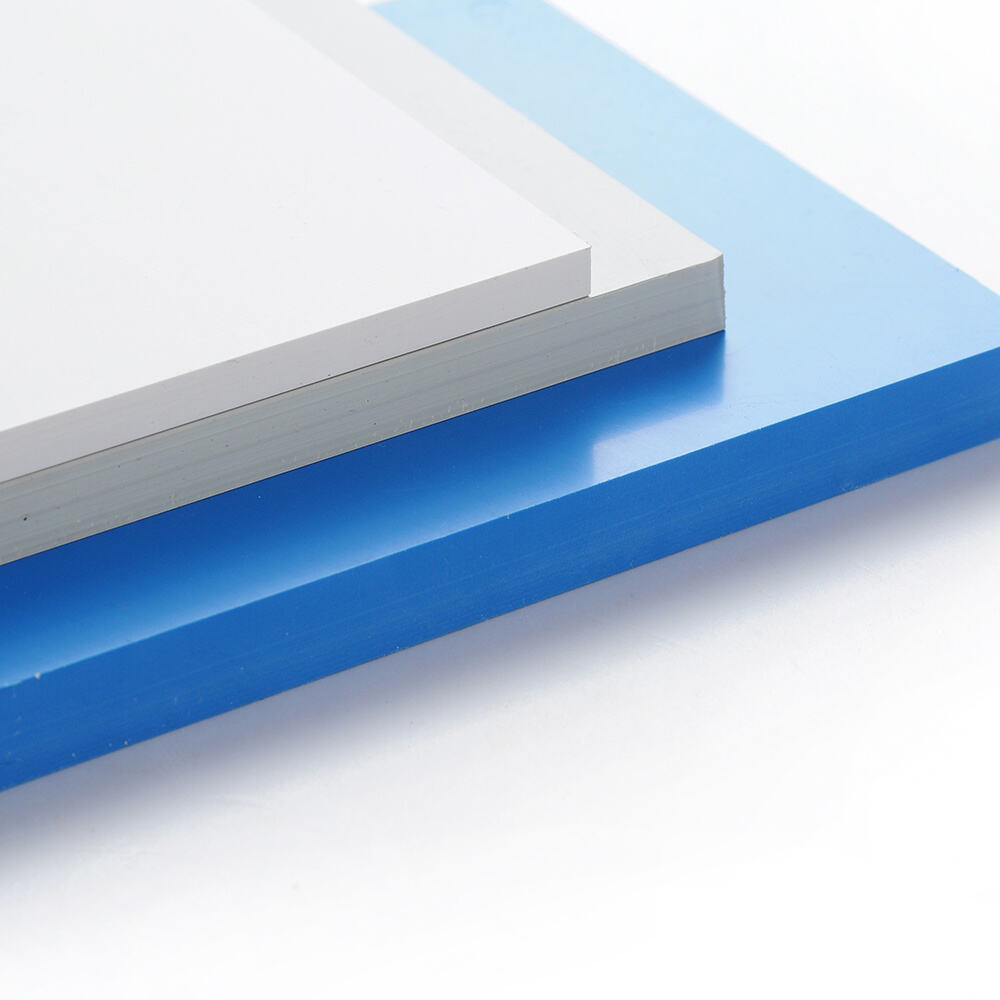

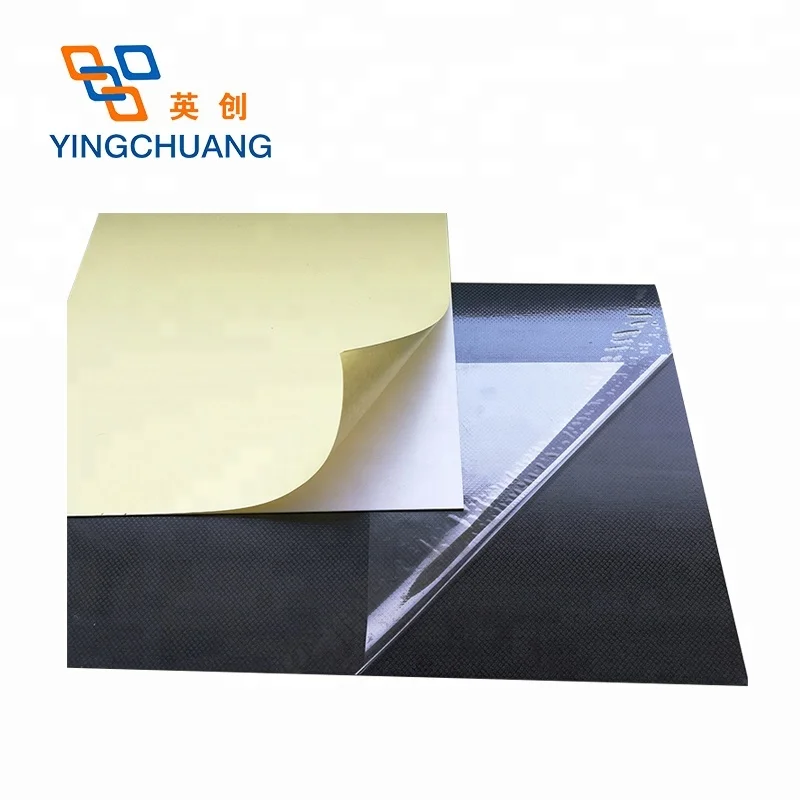

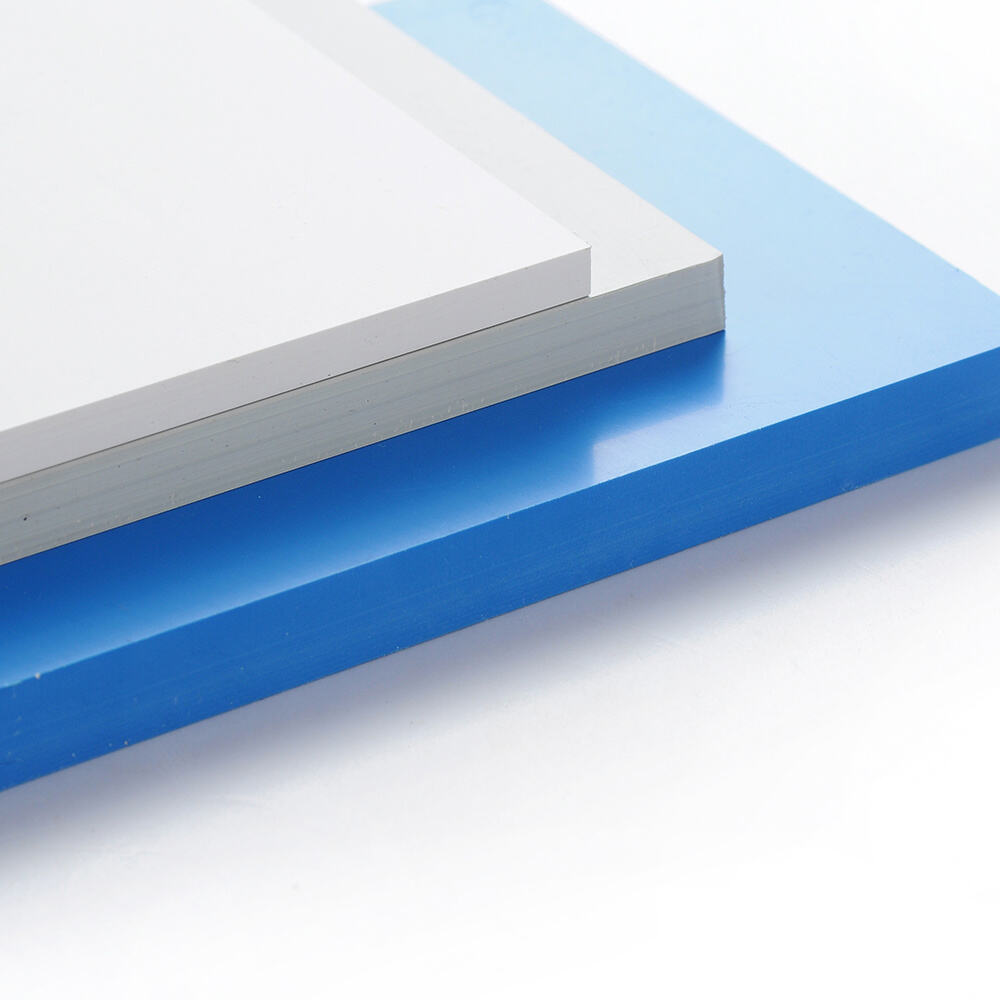

1/4" Thick White PVC Sheet - 4x8 Ft, Smooth Rigid Plastic Board Panel

Industrial-Grade Rigid PVC Sheet: Unmatched Durability for Demanding Environments

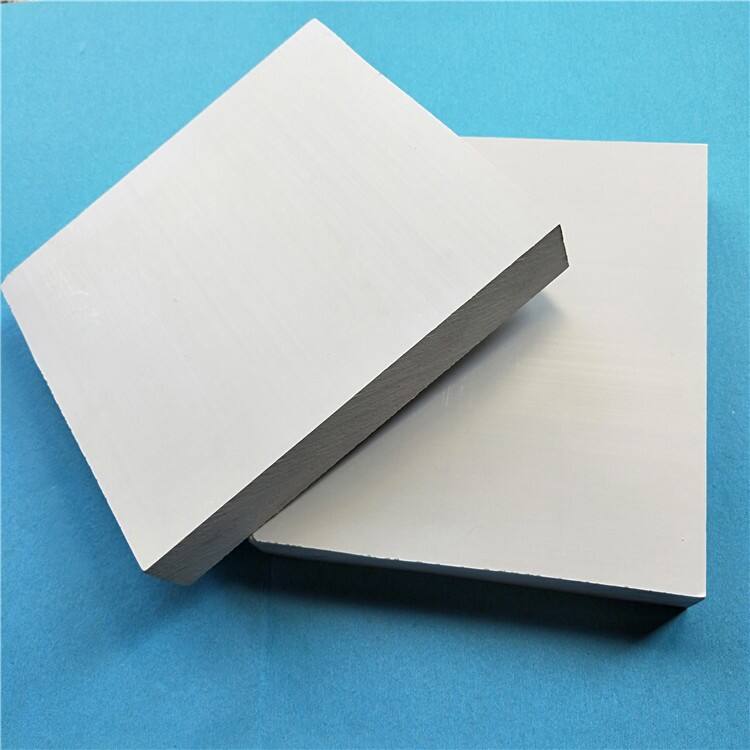

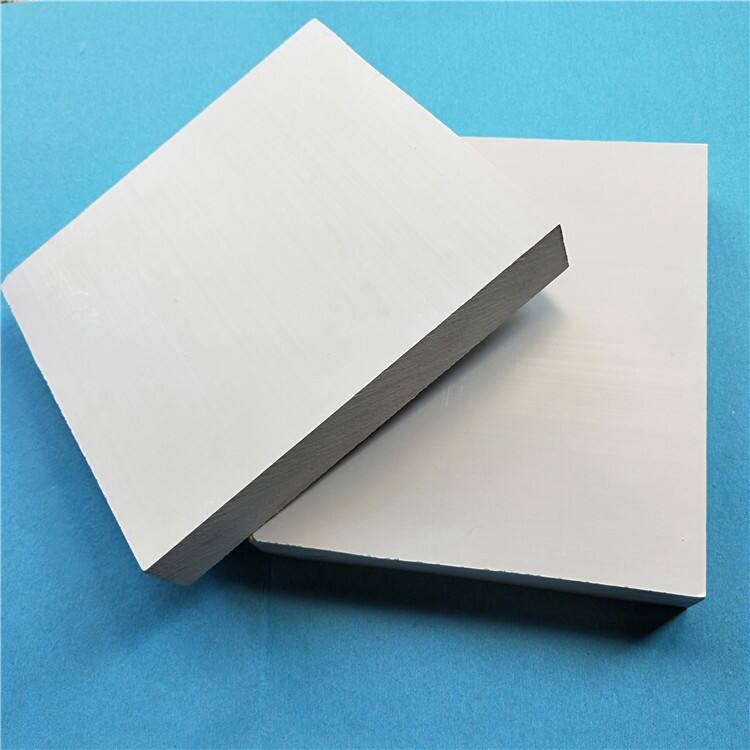

Engineered to withstand the toughest conditions, our Rigid PVC Sheets are the definitive solution for industrial and architectural applications requiring superior strength and chemical resistance. Manufactured from high-density polyvinyl chloride, these sheets deliver exceptional impact resistance, structural integrity, and long-term dimensional stability. A key advantage is their inherent flame retardancy, typically meeting UL94 V-0 rating, making them a safe choice for regulated environments.

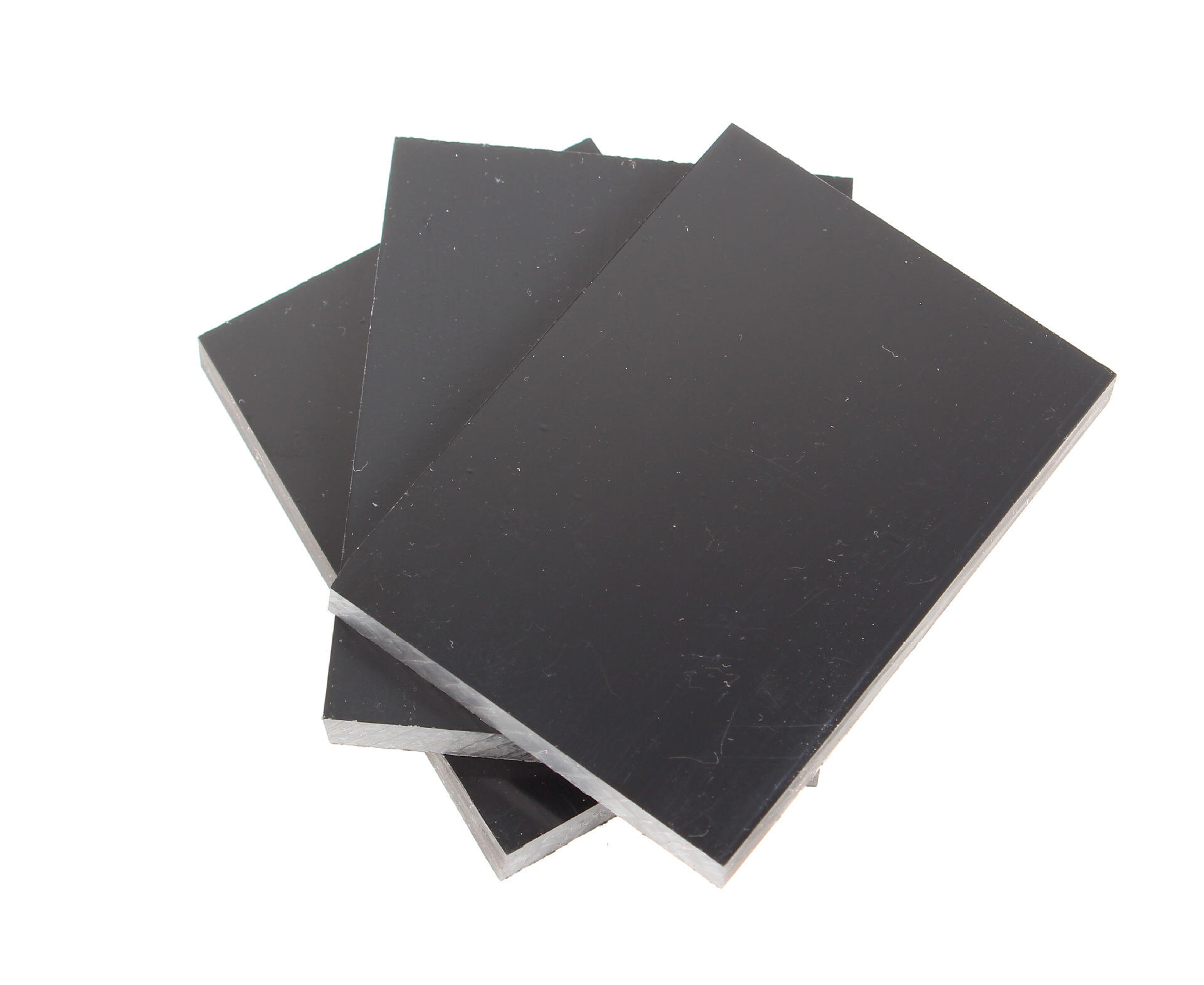

This material is impervious to moisture, acids, alkalis, oils, and most corrosive chemicals, preventing rust, rot, and degradation. It is an ideal, non-conductive alternative to metal for electrical enclosures, chemical fume hoods, tank linings, and process equipment fabrication. The sheets can be easily machined, thermoformed, and welded using standard workshop tools, allowing for complete customization. Choose from a range of thicknesses (from 1mm to 30mm) and standard sheet sizes for your project needs.

- Overview

- Recommended Products

Industrial-Grade Rigid PVC Sheet: Unmatched Durability for Demanding Environments

Engineered to withstand the toughest conditions, our Rigid PVC Sheets are the definitive solution for industrial and architectural applications requiring superior strength and chemical resistance. Manufactured from high-density polyvinyl chloride, these sheets deliver exceptional impact resistance, structural integrity, and long-term dimensional stability. A key advantage is their inherent flame retardancy, typically meeting UL94 V-0 rating, making them a safe choice for regulated environments.

This material is impervious to moisture, acids, alkalis, oils, and most corrosive chemicals, preventing rust, rot, and degradation. It is an ideal, non-conductive alternative to metal for electrical enclosures, chemical fume hoods, tank linings, and process equipment fabrication. The sheets can be easily machined, thermoformed, and welded using standard workshop tools, allowing for complete customization. Choose from a range of thicknesses (from 1mm to 30mm) and standard sheet sizes for your project needs.

|

|

|

|

| Specifications: | Place of Origin: China |

| Brand Name: YINGCHUANG | |

| Thickness: 1mm to 32mm. | |

| Width: 1220mm, 1560mm, 2050mm, etc. | |

| Length: Customizable based on actual needs, with 2440mm and 3050mm being common. |

Chemical Processing Tanks • Machine Guards & Safety Shields • Industrial Partitions • Laboratory Work Surfaces • Electrical Enclosures • Corrosion-Resistant Ductwork.

Key Advantages of PVC Rigid Sheet for Industrial Solutions:

Superior Structural Integrity: Offers high strength-to-weight ratio and dimensional stability, maintaining its shape under load and across temperature variations, ideal for fabrication into tanks, ducts, and machine parts.

Inherent Flame Retardancy: Possesses excellent natural fire-resistant properties, typically achieving UL94 V-0 rating, making it a safe choice for electrical enclosures and construction in regulated environments.

Exceptional Chemical & Corrosion Resistance: Highly resistant to a broad spectrum of acids, alkalis, salts, and industrial chemicals, ensuring long-term performance in aggressive processing and corrosive atmospheres.

Excellent Electrical Insulation: Serves as a reliable non-conductive barrier for electrical components and assemblies, providing both safety and protection.

Outstanding Weathering & UV Stability (When Specified): Formulations with UV inhibitors provide strong resistance to sunlight degradation and weathering, suitable for long-term outdoor applications like signage and architectural cladding.

Q: Can rigid PVC sheet withstand prolonged exposure to chemicals like sulfuric acid or chlorine?

A: Yes, rigid PVC offers excellent resistance to a wide range of acids, alkalis, and salts, including diluted sulfuric acid and chlorine solutions. Always consult our chemical resistance chart for specific concentration and temperature limits before specification.

Q: What are the standard machining guidelines for this material?

A: It can be machined like hardwood. Use carbide-tipped tools with positive rake angles, maintain moderate feed rates, and use air or coolant to prevent heat buildup. For clean cuts, ensure tools are sharp.

Q: Does it comply with industry-specific certifications for food, pharmaceutical, or marine use?

A: We offer specialty grades including NSF/ANSI 51 certified for food contact, USP Class VI for pharmaceutical applications, and grades meeting specific marine flame/smoke/toxicity (FST) requirements for marine interiors.